Manufacturing method of modified terylene segment thrown silk

A manufacturing method and polyester technology, which can be used in melt spinning, textiles and papermaking, etc., can solve the problems of high price of natural hemp fabrics, unfavorable promotion and application, etc., and achieve the effect of unique color effect, rough and bright style, and strong texture of fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

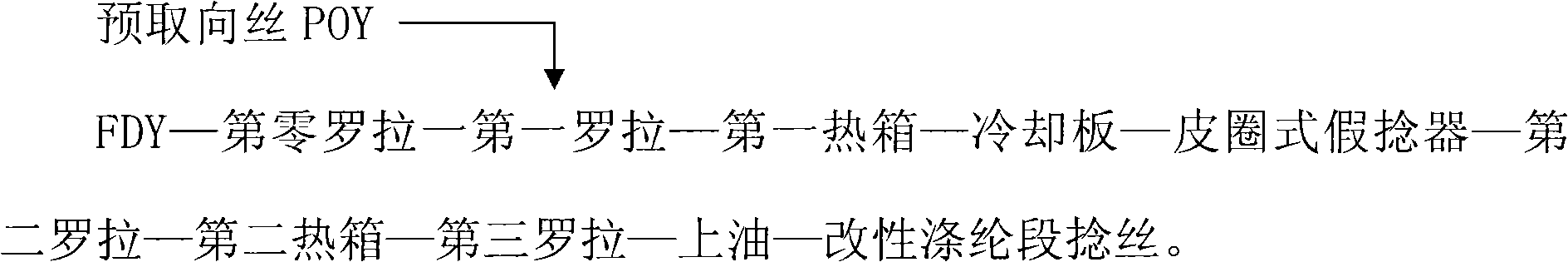

[0015] A method for manufacturing modified polyester section twisted yarn, comprising a spinning process part and a post-processing process part, in the spinning process, the pre-crystallization temperature of cationic modified polyester chips is 150-190 °C, and the drying temperature is 152-150 °C. 192°C, the drawing ratio of the spinning spinneret is above 100, high twist is used in the post-processing process, the wire guide is refitted on the cooling plate to increase the temperature of the setting hot box, and the appropriate second overfeed of 3.0% is selected to increase the strength of the tow Twist effect and twist transfer, forced heat setting at 195°C. The pre-crystallization temperature of the cation-modified polyester chips is 158°C, and the drying temperature is 160°C. The drying conditions of the cation-modified polyester chips in the spinning process are that the water content of the dry chips is controlled below 30 ppm, and the intrinsic viscosity drop of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com