Iron tower foundation of overhead power transmission line severely-weathered rock formation winding anchor rod

A technology for power transmission lines and iron tower foundations, applied in the field of iron tower foundations, can solve problems such as the inability to meet the use requirements of large-load tower foundations, and achieve the effects of improving the lifting load capacity, increasing the bearing capacity of anchor rods, and improving the technical level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

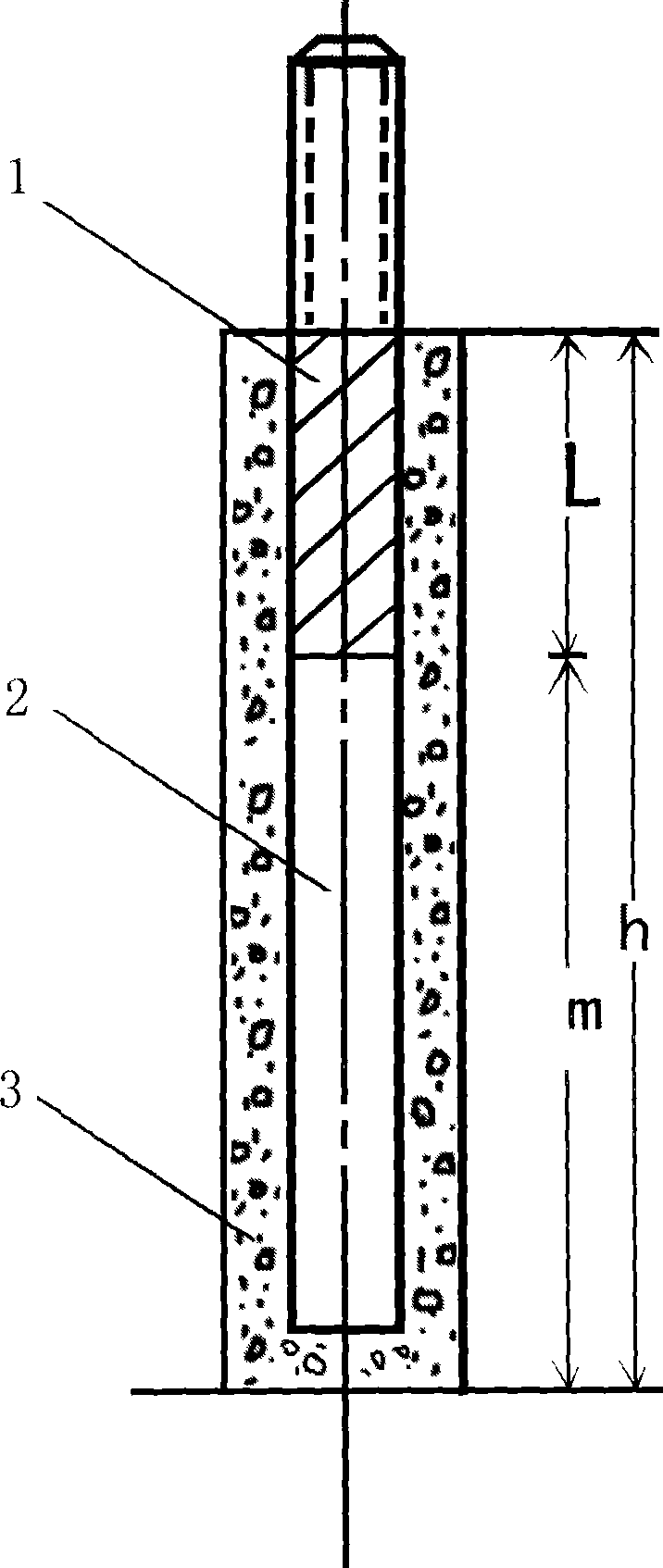

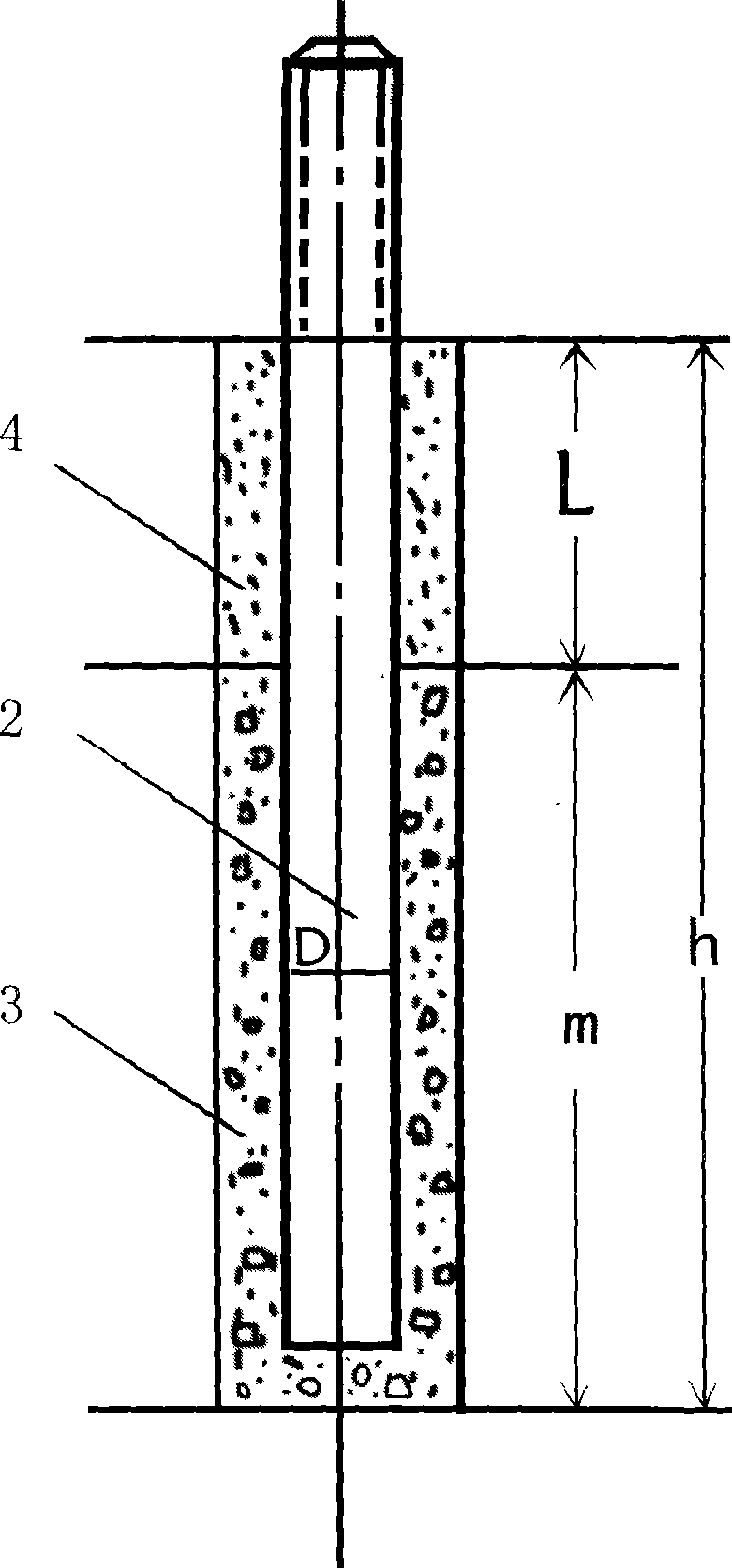

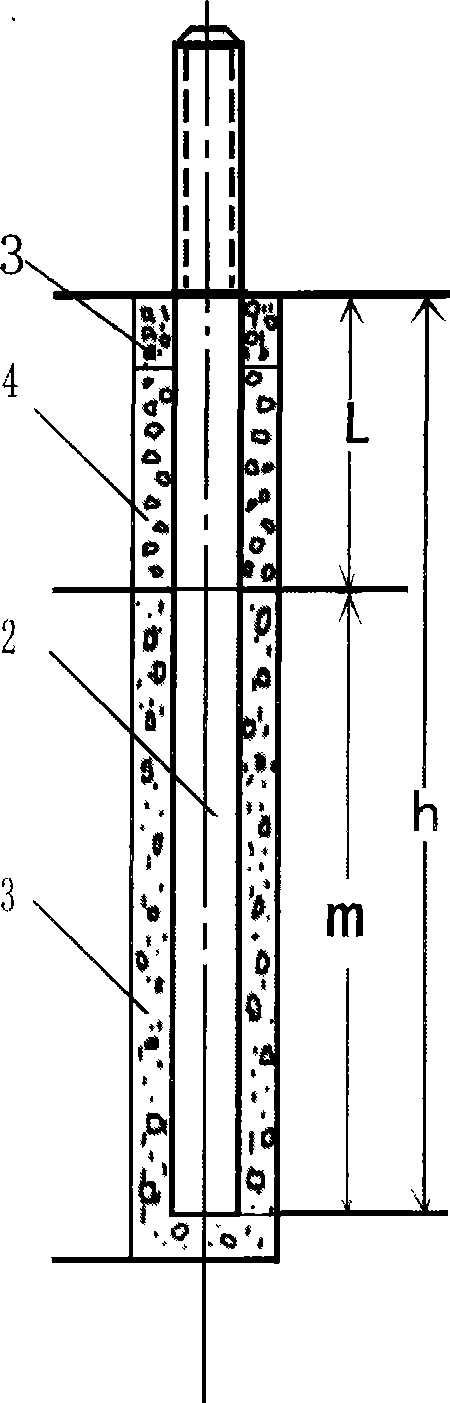

[0024] Such as Figure 1 to Figure 4 as shown, figure 1 It is a schematic diagram of the main structure of the present invention; figure 2 It is the embodiment that the steel bar L section of the present invention is filled with a viscosity-reducing layer; image 3 It is an embodiment in which a filling layer and a concrete layer are sequentially arranged in the L section of the steel bar of the present invention from bottom to top; Figure 4 It is an embodiment of the present invention for corner or tension tower base.

[0025] According to the conventional method, one end has a screw thread, the diameter is 60mm, and the steel bar 2 with an effective length of 4 meters, extending downward from the lower end of the threaded section to 1 meter is the L section, and the L section is at least uniformly dense with a commercially available wide plastic tape. Wrap one layer; then use a combined light drilling rig to drill a hole with a diameter of 120mm and a depth of 4.15 mete...

Embodiment 2

[0027] Bolts with a diameter of 110mm and an effective length of 4 meters are processed, and the L section is 0.5 meters; a drilling machine is used to form a rock hole with a diameter of 130mm and a depth of 4 meters on the strongly weathered rock formation, and then the bolt is placed in the rock hole for positioning Pour fine concrete 3 to the upper end of the anchoring section m, that is, 3.5 meters, pour sand from the rock opening after the strength is up, and use the submersion method to compact the sand layer at the rock opening, and the L section becomes the filling layer 4, or pour in The fine stone is tamped to the rock hole to form a single anchor rod; the tower foundation is formed according to conventional techniques.

Embodiment 3

[0029] Process anchor bolts with a diameter of 100mm and an effective length of 5 meters. The rock hole diameter is 130mm and the depth is 5.15 meters. In order to increase the strength, pour fine stones from the rock hole to 4.5 meters for compaction, and then pour fine stone concrete 3 to the rock hole, so as to have a high pull-up force and a good resistance level. force. Other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com