Instant fresh cake produced from hydrophilic materials and method for producing the same

A hydrophilic and material technology, applied in food preparation, food science, application, etc., can solve the problems of easy rejuvenation and short shelf life of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

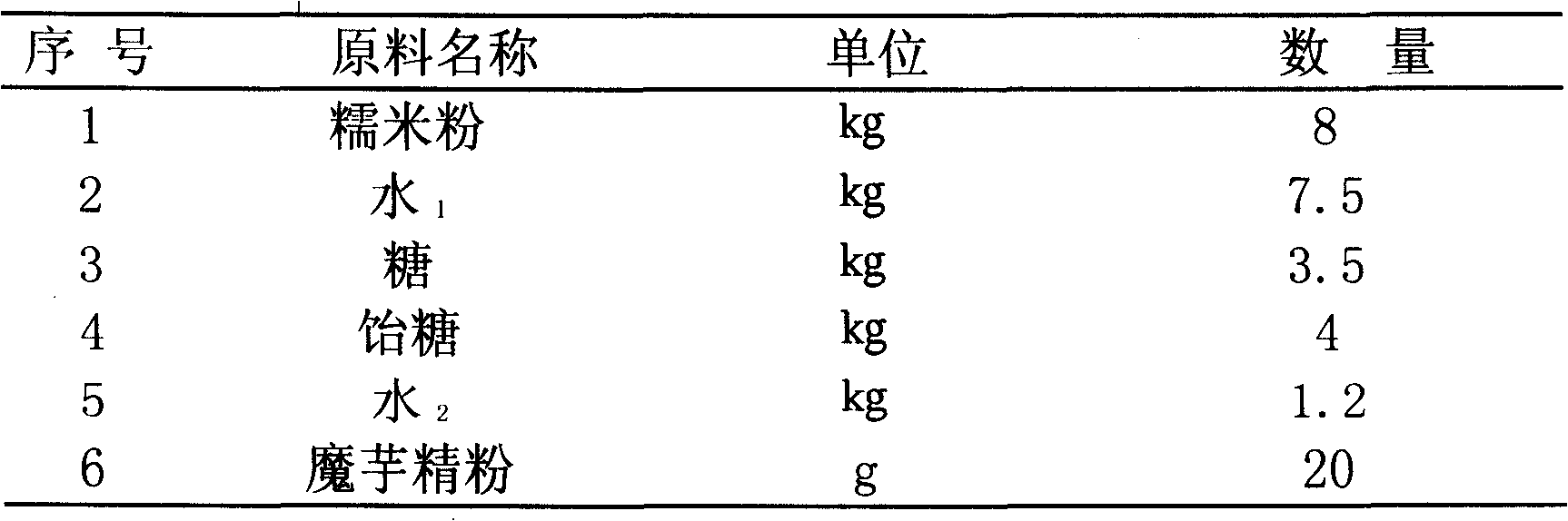

[0014]

[0015] The operation method of cake dough:

[0016] 1. Stir for the first time: first pour the glutinous rice flour and water into the dough mixer and stir for about 20 minutes.

[0017] 2. Pour into the tray: Pour the above ingredients into 4 steaming trays (the size is about 60×40×5cm) and spread them out.

[0018] 3. Steaming: Put the raw material tray into the steaming cabinet for steaming, and it will take 45 minutes from the time of boiling (steaming).

[0019] 4. Gelatinization of konjac flour: add water 2 Heat to boiling, pour in the diluted konjac powder, stir while heating, until it boils again, remove from the heat when the material liquid is uniform, and cool down for later use.

[0020] 5. Secondary stirring: Pour the steamed clinker into the dough mixer, accurately measure the amount of white sugar, caramel, and konjac paste, and put it into the dough mixer, and stir for 5 minutes. The dough that is stirred contains 8 kilograms of glutinous rice fl...

Embodiment 2

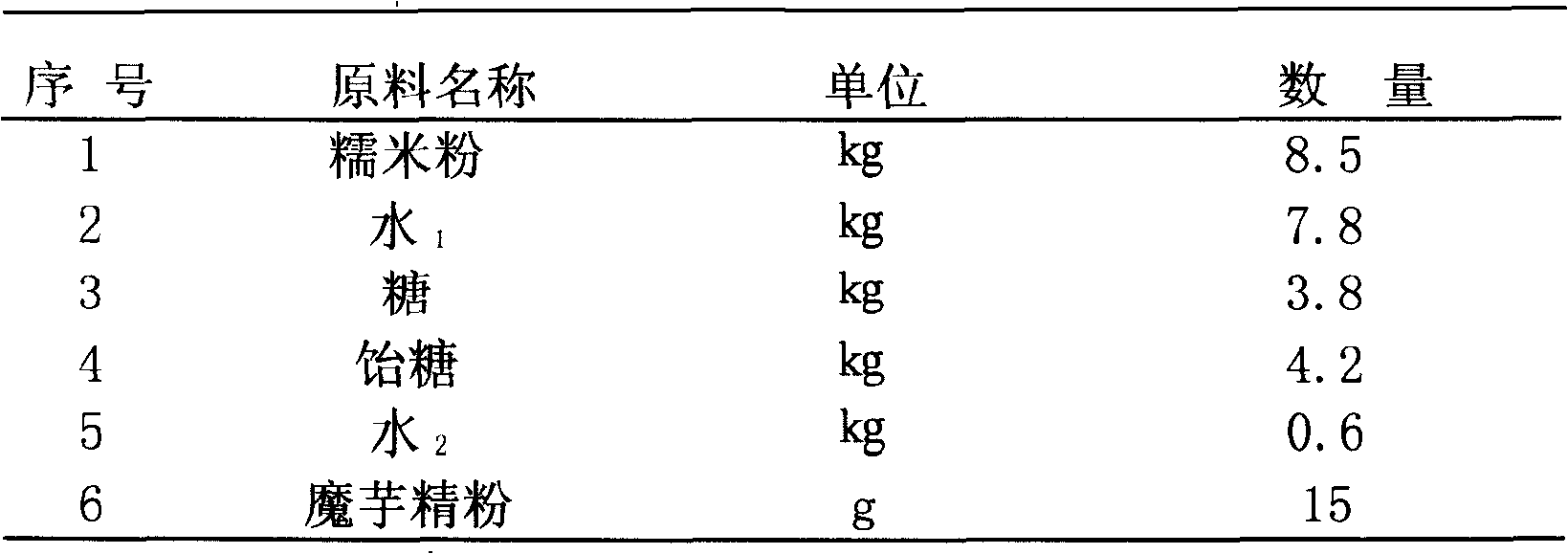

[0023]

[0024] The operation method of cake dough:

[0025] 1. Stir for the first time: first accurately measure the amount of glutinous rice flour and water, pour it into the dough mixer, and stir for about 25 minutes.

[0026] 2. Pour into the plate: Pour the above ingredients evenly into 4 steaming plates (size about 60×40×5cm), and spread them evenly.

[0027] 3. Steaming: Put the raw material tray into the steaming cabinet and steam it. It will take about 55 minutes to start timing from boiling (steaming).

[0028] 4. Gelatinization of konjac flour: water 2 Heat to boiling, pour in the diluted konjac powder, stir while heating, until it boils again, remove from the heat when the material liquid is uniform, and cool down for later use.

[0029] 5. Secondary stirring: Pour the steamed clinker into the dough mixer, accurately measure the amount of white sugar, caramel, and konjac paste, and put it into the dough mixer, and stir for 3 minutes until it is even and smooth...

Embodiment 3

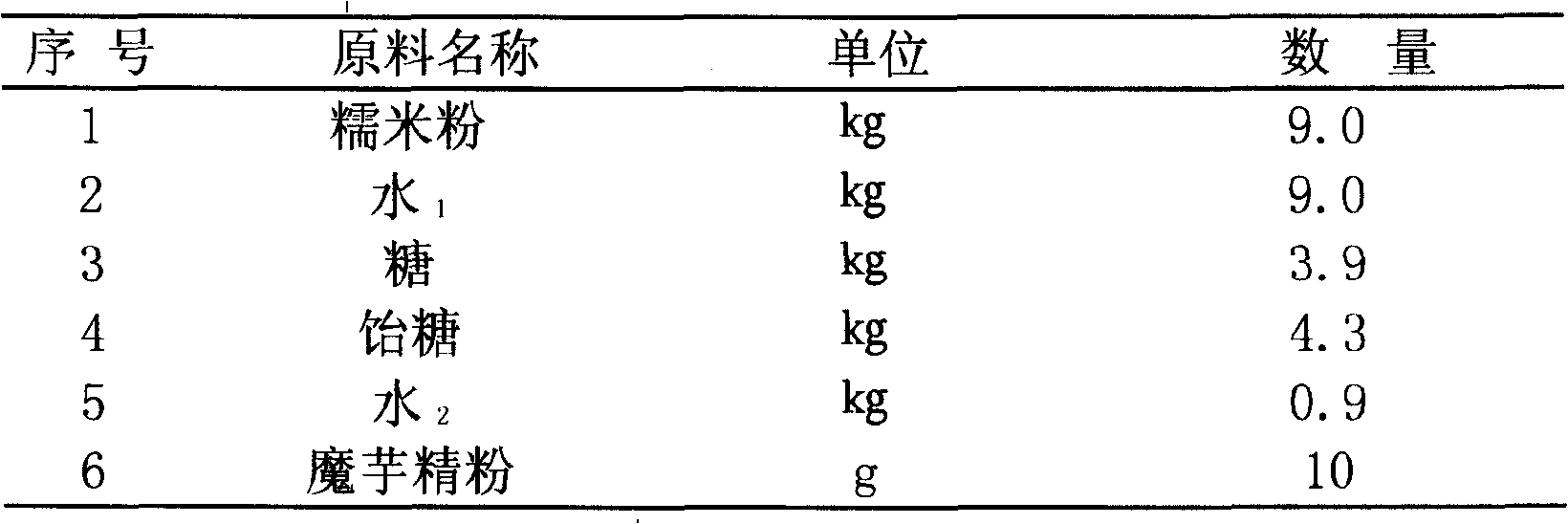

[0032]

[0033] The operation method of cake dough:

[0034] 1. Stir for the first time: first mix glutinous rice flour, water 1 Pour into the dough mixer and stir for about 30 minutes.

[0035] 2. Pour into the plate: Pour the above ingredients evenly into 4 steaming plates and spread them out.

[0036] 3. Steaming: put the tray into the steaming cabinet for steaming, it will take about 60 minutes from the beginning of boiling.

[0037] 4. Gelatinization of konjac flour: add water 2 Heat to boiling, pour in the diluted konjac powder, stir while heating, until it boils again, remove from the heat when the material liquid is uniform, and cool down for later use.

[0038] 5. Secondary stirring: Put the steamed clinker, sugar, maltose, and konjac paste into the noodle mixer and stir for 4 minutes. Divide the uniformly stirred dough and make skins respectively, and wrap sesame stuffing in the skins to make glutinous rice cakes with fillings.

[0039] Results: The finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com