Radiation protection cement and sulphuric acid production method

A production method and radiation protection technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problem of unrealized industrial production, and achieve the unique effect of the batching scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

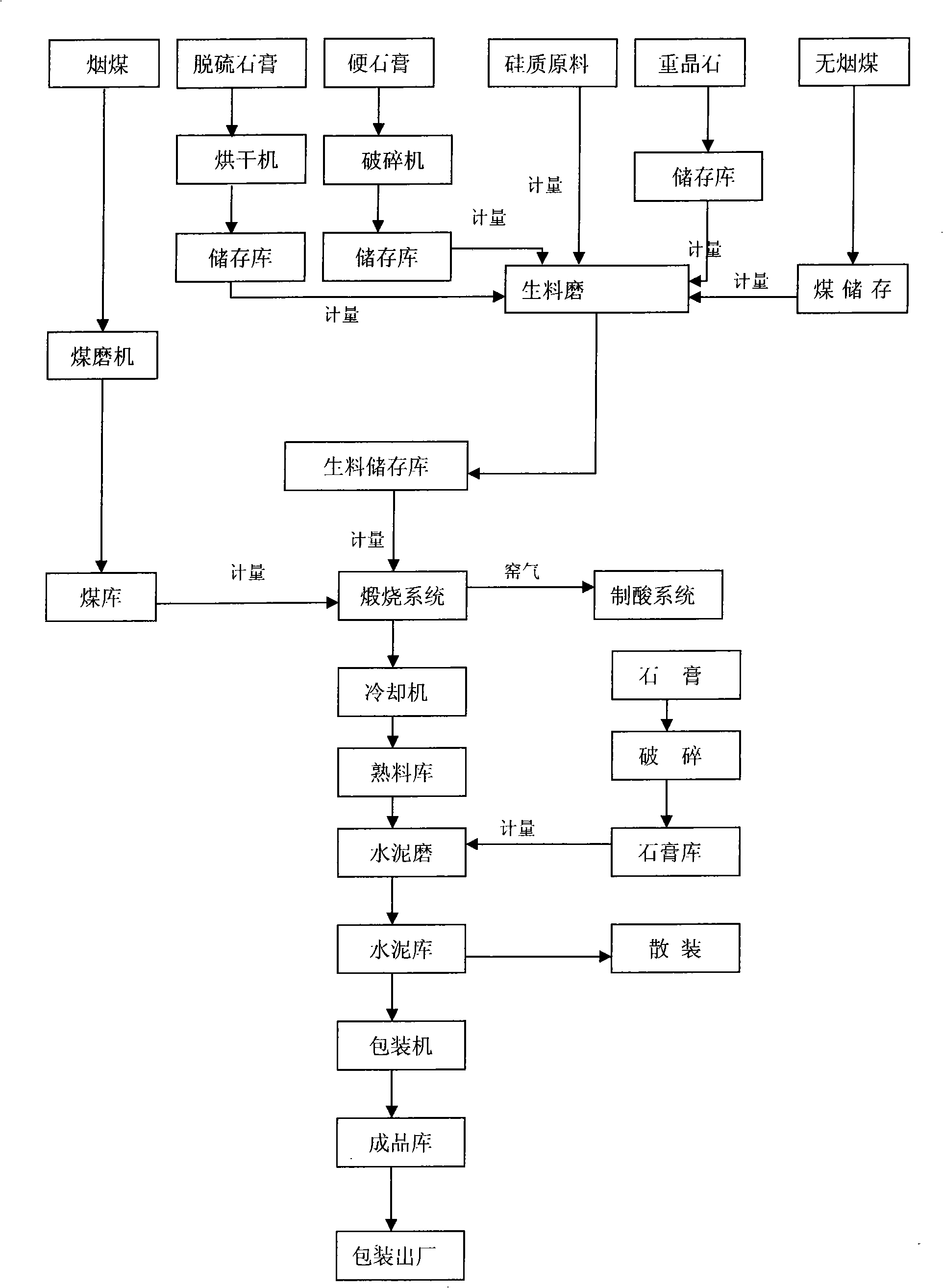

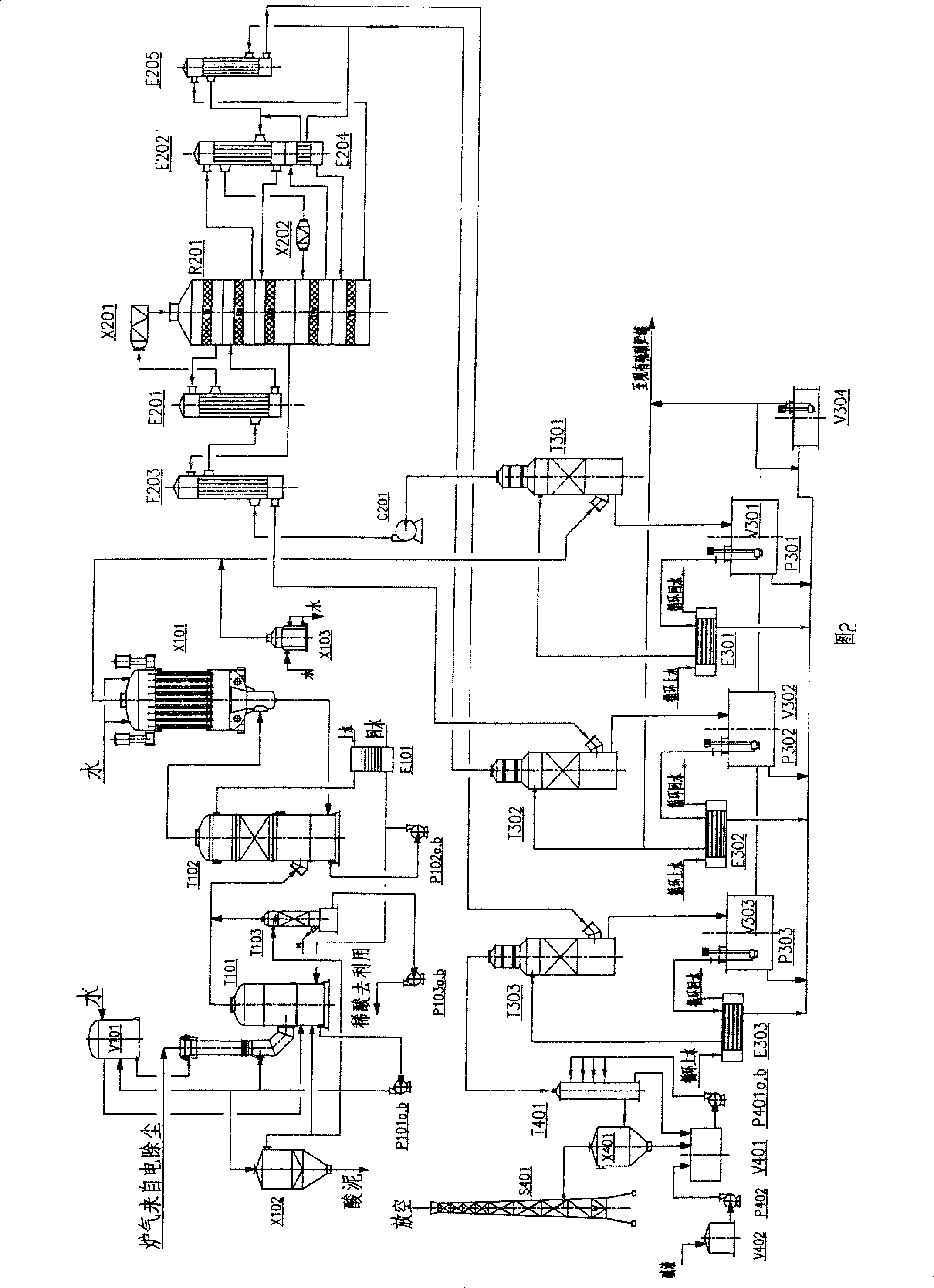

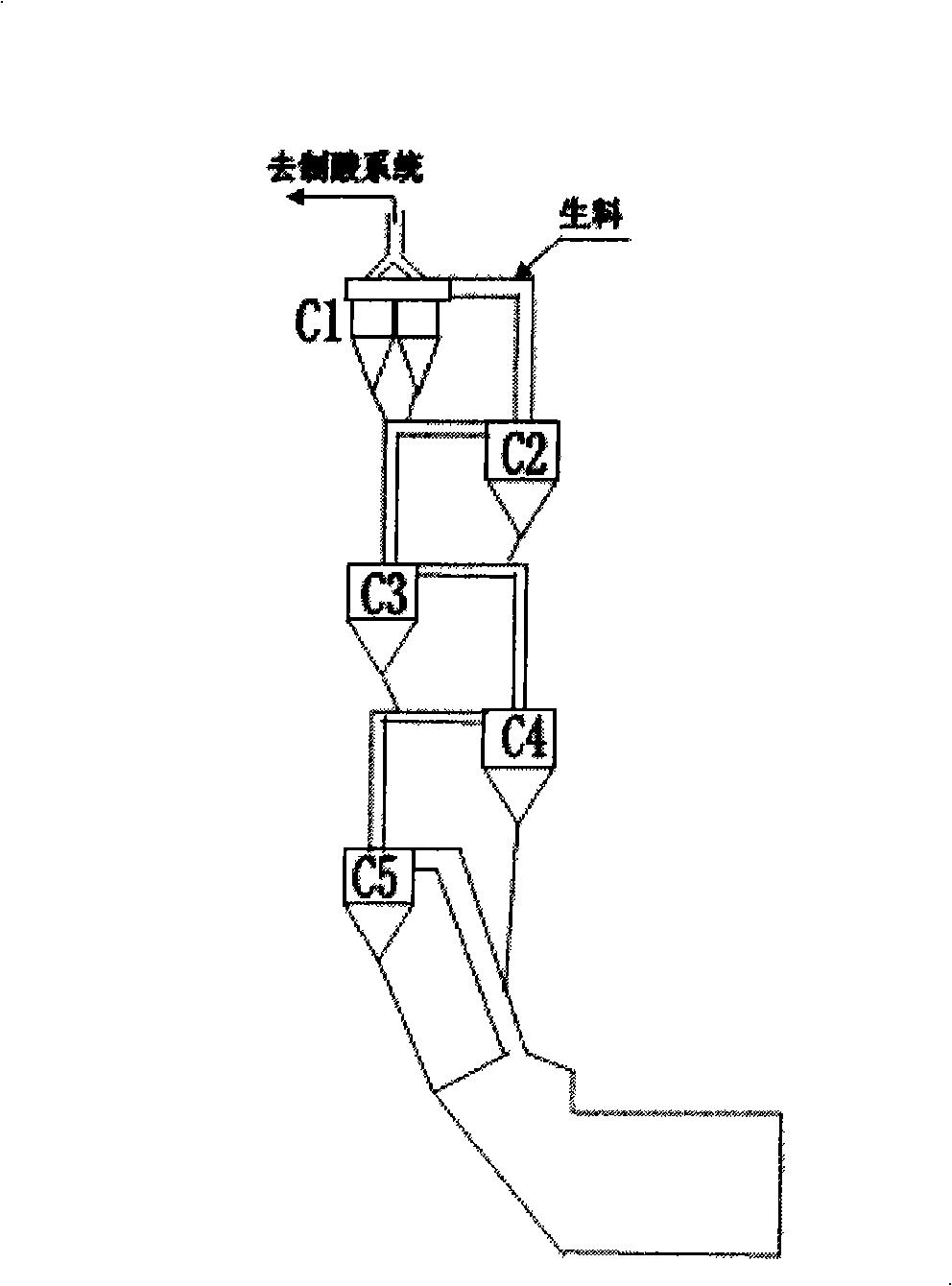

[0020] 1. This method adopts five-stage cyclone preheating technology and "two conversion and two absorption" pickling acid production technology, using desulfurized gypsum, barite, etc. as raw materials to produce barium cement and industrial sulfuric acid with anti-radiation properties. See the process figure 1 , Figure 2 and image 3 , The description is as follows:

[0021] 1. Dry the flue gas desulfurization gypsum to remove all free water and part of the crystal water in the desulfurization gypsum to produce hemihydrate gypsum with a moisture content of 6-9%;

[0022] 2. The anhydrite is crushed by a crusher and then enters the storage warehouse. After crushing, the mass fraction of the anhydrite 20mm sieve is 10-20%;

[0023] 3. After measuring desulfurized gypsum, anhydrite, barite, siliceous raw materials, and anthracite, enter the raw meal mill to prepare raw meal, and enter the raw meal storage warehouse. In the dry state, the mass percentage of each material in the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com