Semiconductor discharged-gas processing device

A technology for exhaust gas and treatment device, applied in the field of semiconductor exhaust gas treatment device, can solve problems such as explosion, flame disappearance, pressure change, etc., and achieve the effect of preventing damage and preventing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

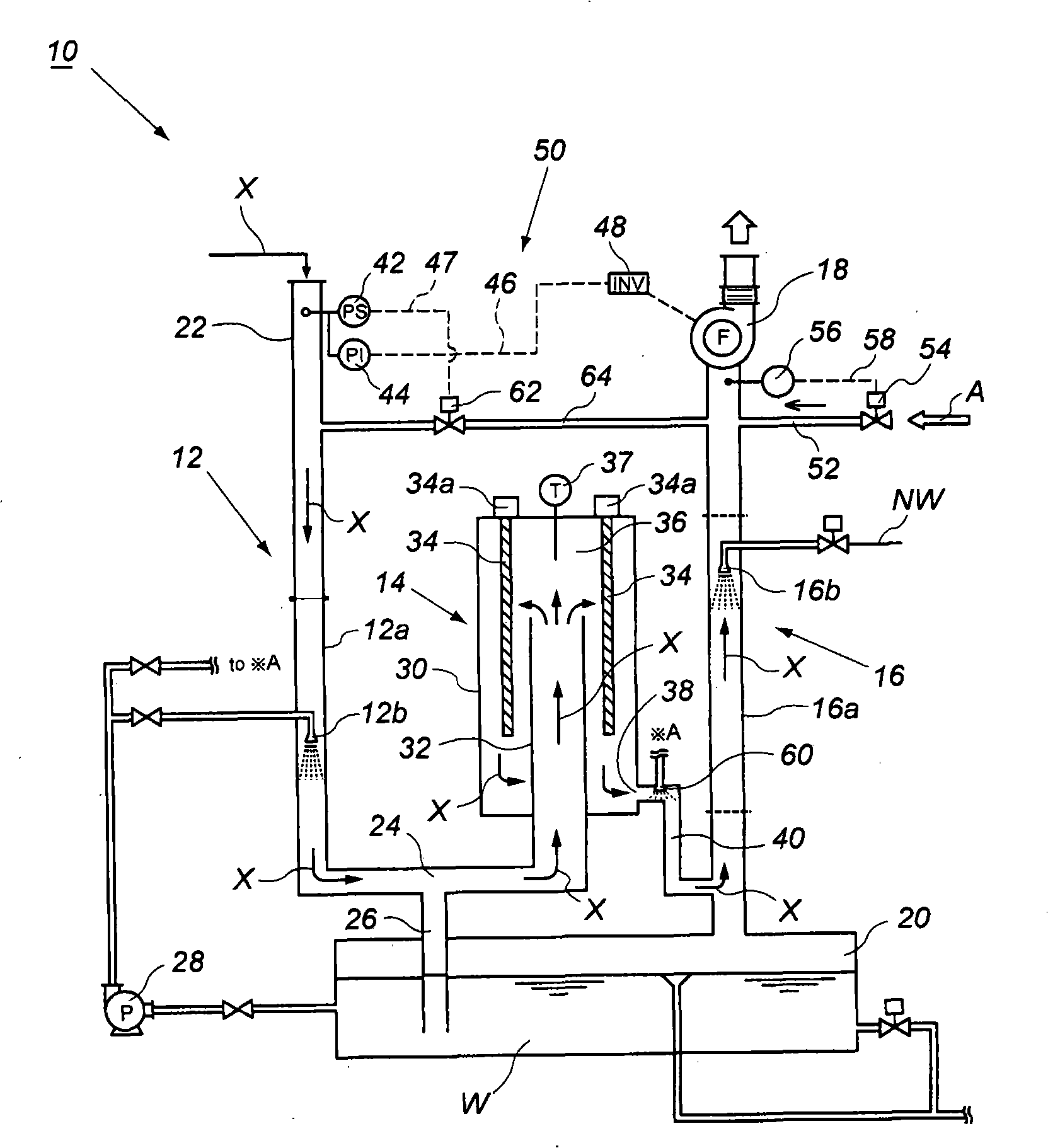

[0063] The invention will be described below with reference to the illustrated embodiments. figure 1 It is a schematic diagram showing the flow of the apparatus of the present invention. As shown in the figure, the semiconductor exhaust gas treatment device 10 of this embodiment is roughly composed of an inlet scrubber 12, a reaction furnace 14, an outlet scrubber 16, an exhaust fan 18, a storage tank 20, and the like.

[0064] The inlet scrubber 12 is used to remove dust or water-soluble gas contained in the semiconductor exhaust gas X introduced into the reaction furnace 14. It has a straight cylindrical scrubber body 12a, and is arranged inside the scrubber body 12a. The nozzle 12b sprays water W or chemical solution in the form of a spray near the top.

[0065] The top of the inlet scrubber 12 is connected to the semiconductor manufacturing equipment (not shown) of the factory through the inlet pipe 22, and various semiconductor exhaust gases X discharged in the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com