Double-face nanometer band electrode array integration sensor capable of being cut and method for manufacturing same

An integrated sensor and electrode array technology, applied in the field of chemical and biological sample detection, can solve complex problems, achieve the effect of less interference, fast measurement, and less sample solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

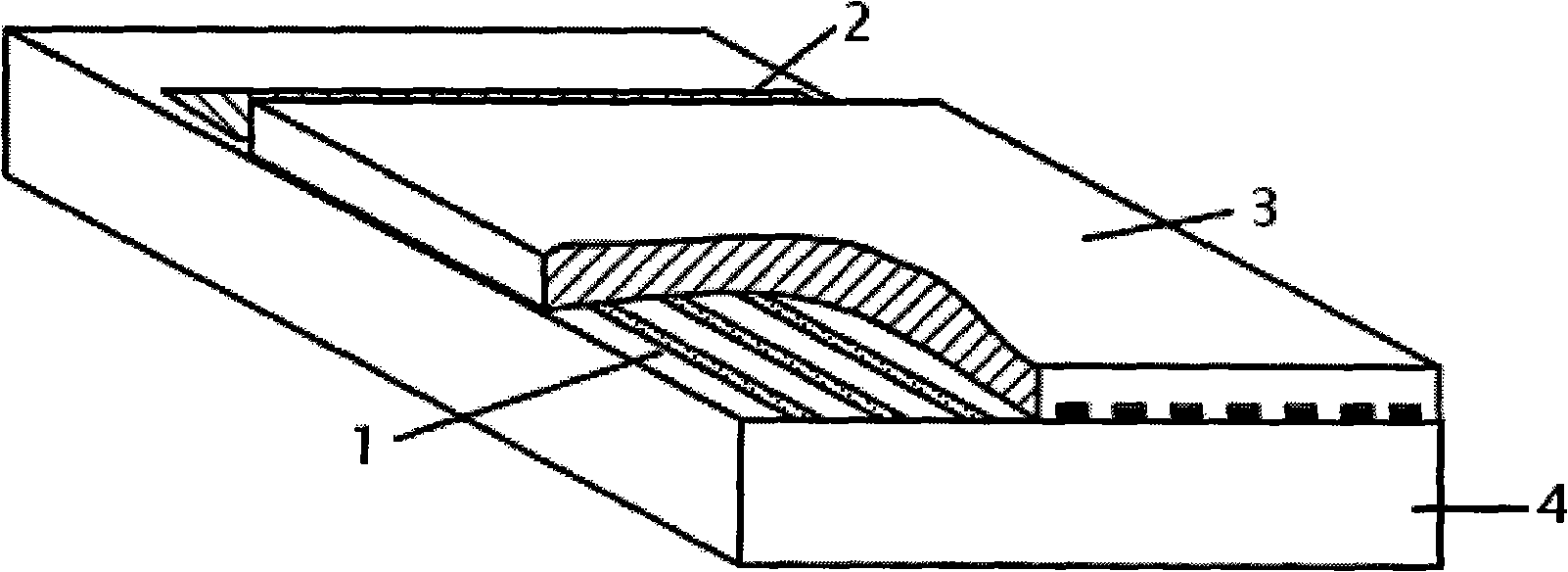

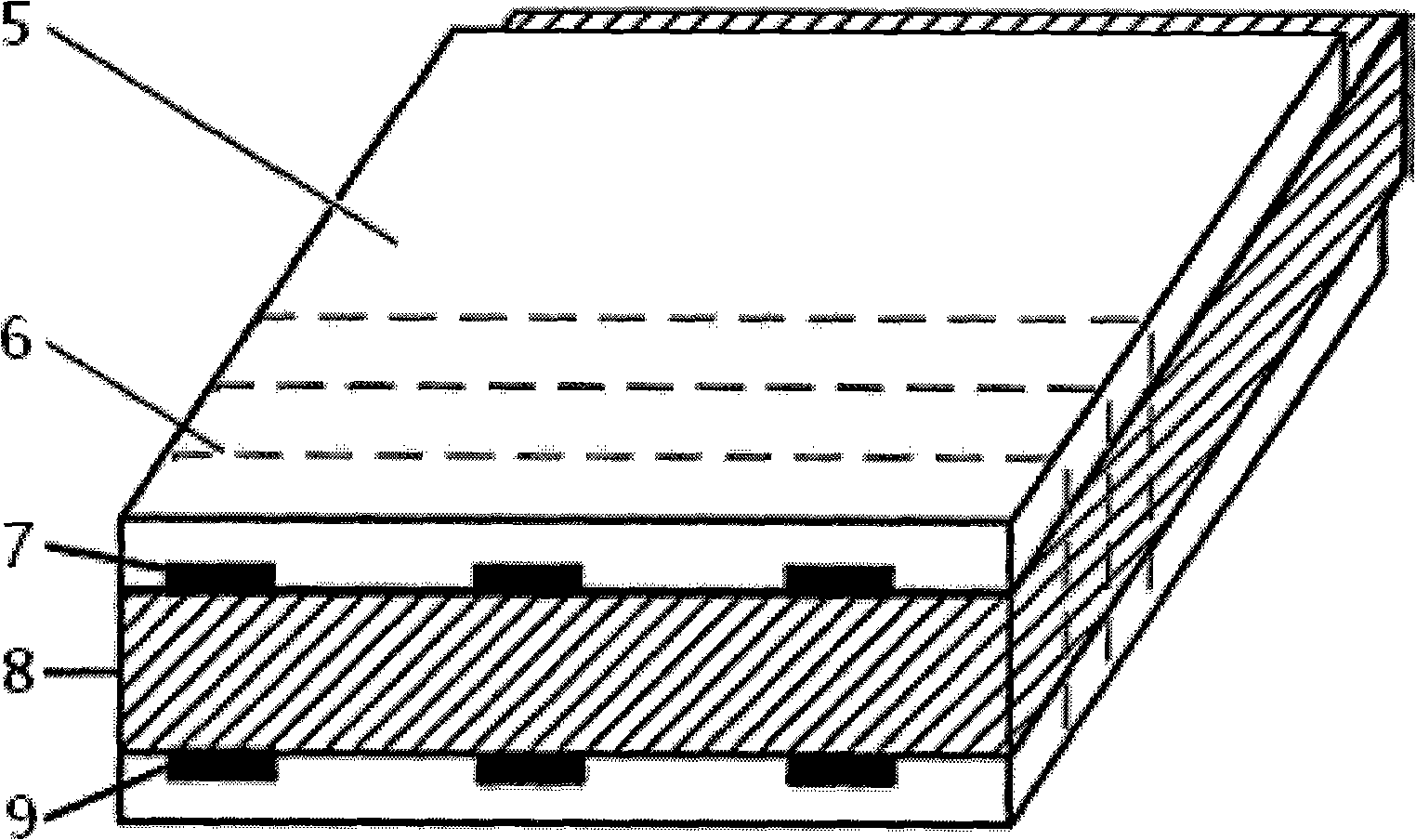

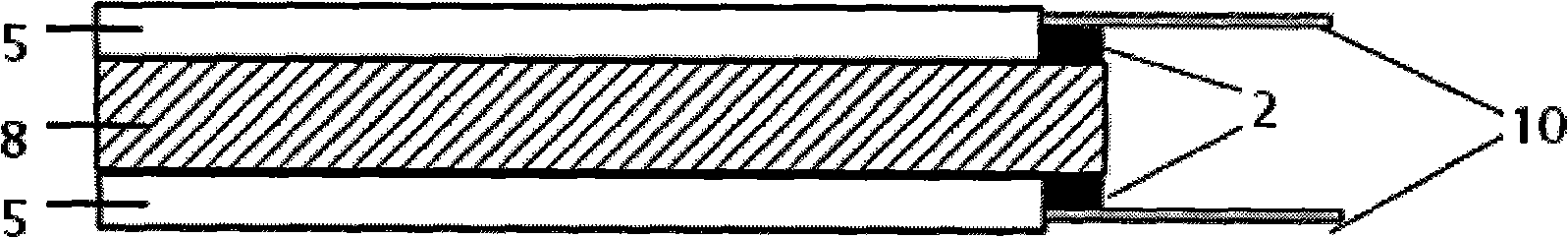

[0027] Such as figure 2 , image 3 As shown, the present invention includes a substrate, an electrode, an insulating layer, and a bonding pad. Choose silicon wafer or glass as Si / SiO 2 Substrate 8, using MEMS technology to deposit two different electrode materials on the front and back planes of the substrate to form Au working electrode 7 and Pt reference electrode 9 respectively, using photolithography technology to form a comb-shaped Au working electrode with upper and lower symmetry 7 and Pt reference electrode 9 arrays, with Si deposited on both sides of the comb-shaped working electrode and reference electrode by PECVD method 3 N 4 The insulating layer 5 is exposed to the pad 2 by photolithography, and a plurality of cutting lines 6 perpendicular to the electrode direction are engraved on both insulating layers.

[0028] The thicknesses of the Au working ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com