PVDC copolymerization emulsion, preparation and uses thereof

A copolymerization emulsion and copolymerization technology, which is applied in the direction of textiles, papermaking, coatings, paper coatings, etc., can solve the problems of PVDC emulsion discoloration, unsatisfactory use, and insufficient softness of the coating film, and achieve strong adhesion, good elasticity, and white color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

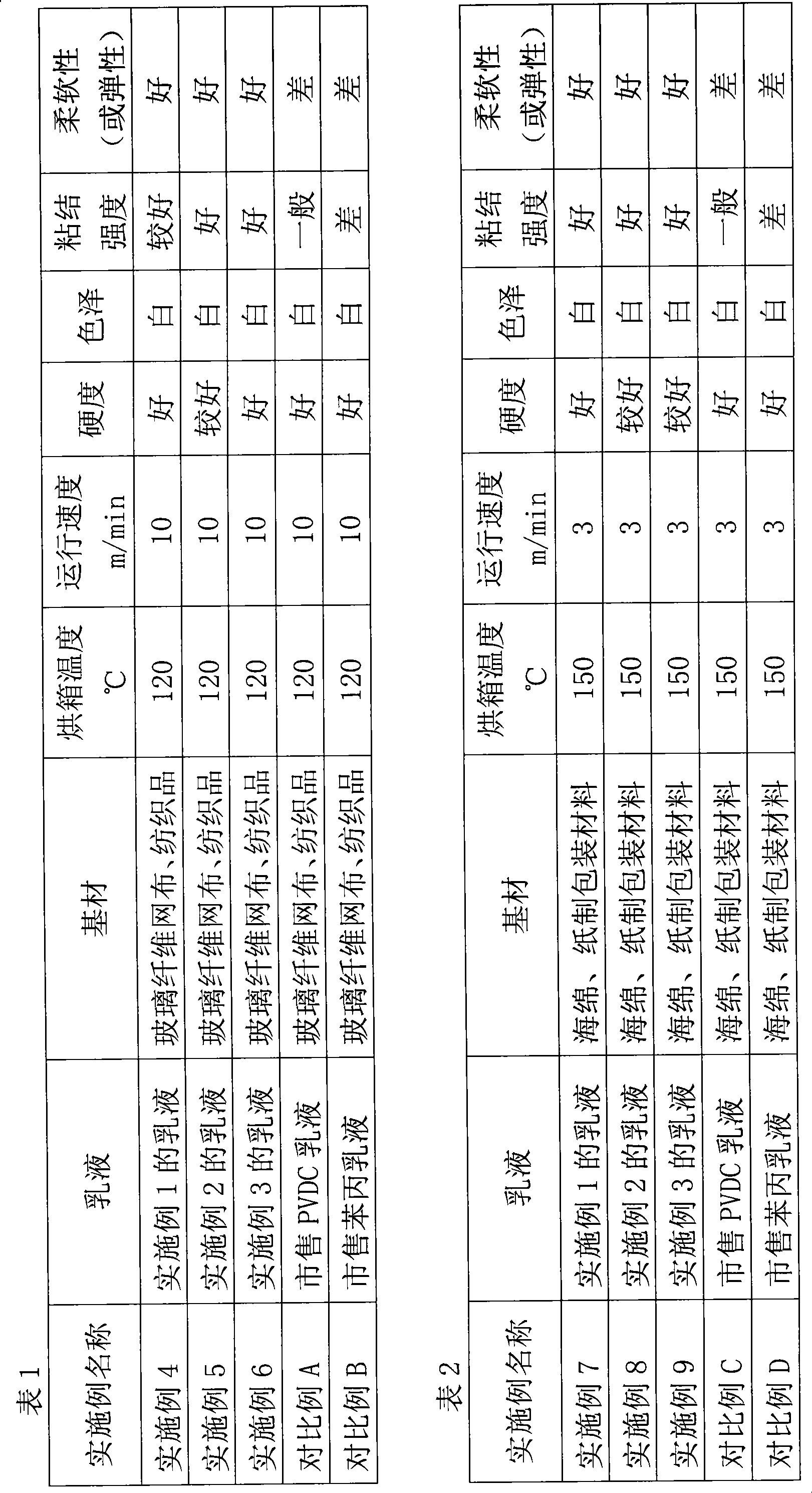

Examples

Embodiment 1

[0033] Preparation of PVDC Copolymer Emulsion

[0034] Components:

[0035] Mixed monomer: vinylidene chloride (VDC) 40kg

[0036] Methyl methacrylate (MMA) 2kg

[0037] Butyl Acrylate (BA) 12kg

[0038] Acrylic acid (AA) 2kg

[0039] Perfluoroalkyl ethyl acrylate 0.28kg

[0040] Soft water 45kg

[0041] Emulsifier: sodium secondary alkylbenzene sulfonate 0.9kg

[0042] A501 0.5kg

[0043] Initiator: Ammonium persulfate 35g

[0044] Sodium thiosulfate 25g

[0045] pH regulator: Glacial acetic acid 0.05kg

[0046] Operation method: In a 100L stainless steel reaction kettle, add 28kg of soft water, 0.058kg of sodium secondary alkylbenzene sulfonate, 0.07kg of A501, and 0.025kg of a pH regulator in the first stage. kg methyl methacrylate, 2.816 kg butyl acrylate and 0.16 kg acrylic acid mixed monomer, control the stirring speed to 100 rpm, stir for 5 minutes and then raise the temperature to 45°C, add dropwise 2 g ...

Embodiment 2

[0049] Repeat Example 1, the difference between this embodiment and Example 1 is that the components of the mixed monomers are:

[0050] (1) Vinylidene chloride (VDC) 38kg

[0051] (2) Methyl methacrylate (MMA) 2kg

[0052] (3) Butyl acrylate (BA) 14kg

[0053] (4) Acrylic acid (AA) 2kg

[0054] (5) Perfluoroalkyl ethyl acrylate 0.28kg

[0055] Results: A copolymer emulsion with a three-layer structure with a solid content of 56% was obtained: the core layer was 30% VDC and 70% comonomer, the middle layer was 80% VDC and 20% comonomer, and the outermost layer was 43% VDC and 57% comonomer and 0.5% C 3~6 Perfluoroester, the ratio of each layer is 10:70:20.

Embodiment 3

[0057] Repeat Example 1, the difference between this embodiment and Example 1 is that in the first stage of the operation method, add 4.2kg vinylidene chloride, 3.72kg butyl acrylate, add 27.552kg vinylidene chloride, 4.048 kg in the second stage kg butyl acrylate.

[0058] Results: A copolymer emulsion with a three-layer structure with a solid content of 56% was obtained: the core layer was 50% VDC and 50% comonomer, the middle layer was 82% VDC and 18% comonomer, and the outermost layer was 57.4% VDC and 42.6% comonomer and 0.5% C 3~6 Perfluoroester, the ratio of each layer is 15:60:25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com