Volume scattering polymer light conducting plate and preparation method for injection mould master batch

A technology of polymers and light guide plates, applied in optics, light guides, optical components, etc., can solve the problems affecting the uniformity of light scattering, complex preparation process, and unsatisfactory, and achieve excellent performance and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

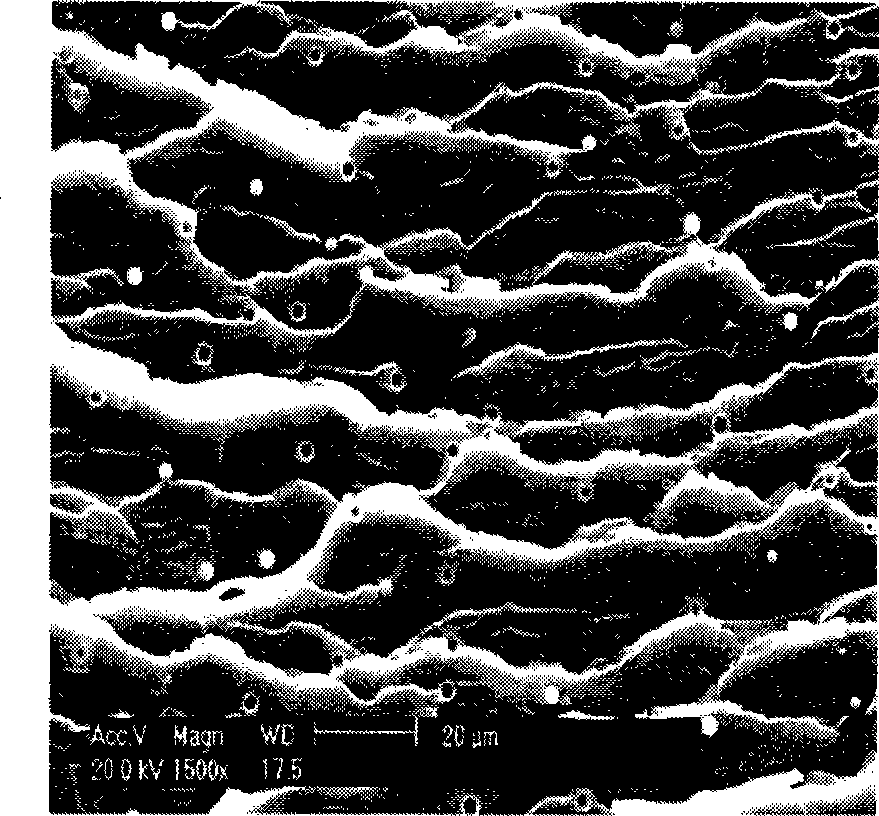

[0032] Preparation of injection molding masterbatch, the organic matrix material is polymethyl methacrylate, and the inorganic scattering particles are SiO 2 , whose particle size is 0.1 μm; comprising the following steps:

[0033] (a) Under the action of ultrasonic stirring environment (ultrasonic power is 1200W, frequency is 30KHZ), carry out surface treatment to inorganic body scattering particles with absolute ethanol, coupling agent MPS and dibutyl phthalate for 20 minutes; inorganic body The mass ratio of scattering particles to absolute ethanol, coupling agent MPS and dibutyl phthalate is 1:0.25:0.005:0.05;

[0034] (b) mixing the treated inorganic scattering particles and the organic matrix material, and mechanically stirring the mixed material to uniformly mix the inorganic scattering particles and the organic matrix material; the inorganic scattering particles account for 20% by weight in the mixed material;

[0035] (c) Extrude, mix, wire-draw and pelletize the mix...

Embodiment 2

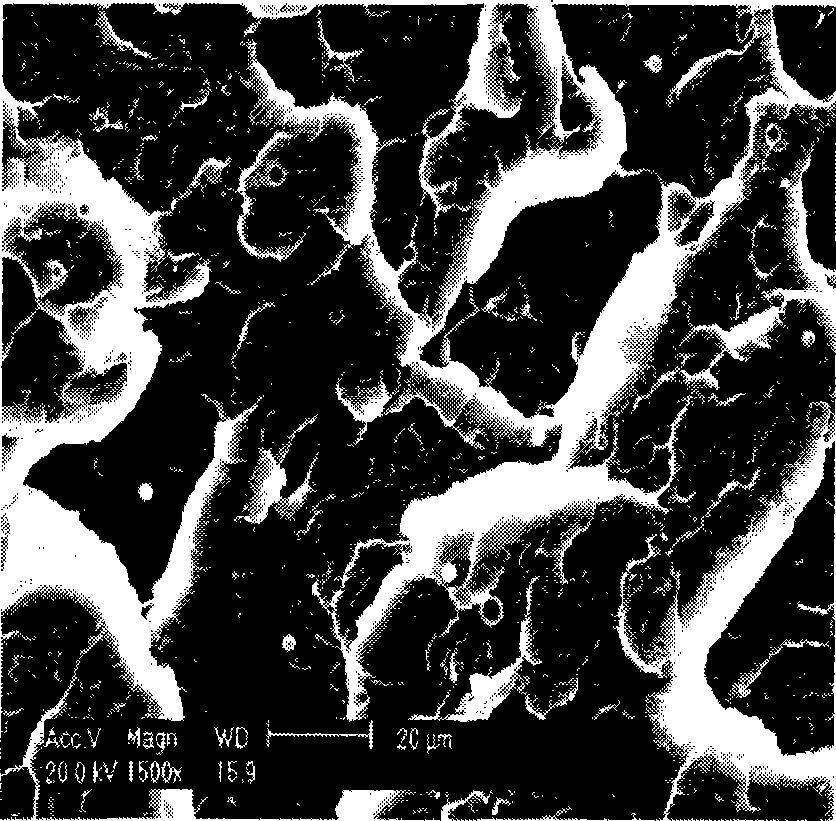

[0037] Preparation of injection molding masterbatch, the organic matrix material is polymethyl methacrylate, and the inorganic scattering particles are TiO 2 , whose particle size is 1 μm; comprising the following steps:

[0038] (a) Under the action of ultrasonic stirring environment (ultrasonic power is 800W, frequency is 20KHZ), carry out surface treatment on inorganic body scattering particles with absolute ethanol, coupling agent MPS and dibutyl phthalate for 100 minutes; inorganic body The mass ratio of scattering particles to absolute ethanol, coupling agent MPS and dibutyl phthalate is 1:0.1:0.0005:0.005;

[0039] (b) mixing the treated inorganic scattering particles and the organic matrix material, and mechanically stirring the mixed material to uniformly mix the inorganic scattering particles and the organic matrix material; the inorganic scattering particles account for 10% by weight in the mixed material;

[0040] (c) Extrude, mix, wire-draw and pelletize the mixe...

Embodiment 3

[0042] Preparation of injection molding masterbatch, the organic matrix material is polymethyl methacrylate, and the inorganic scattering particles are ZrO 2 , whose particle size is 10 μm; comprising the following steps:

[0043] (a) Under the action of ultrasonic stirring environment (ultrasonic power is 2000W, frequency is 40KHZ), carry out surface treatment on inorganic body scattering particles with absolute ethanol, coupling agent MPS and dibutyl phthalate for 10 minutes; inorganic body The mass ratio of scattering particles to absolute ethanol, coupling agent MPS and dibutyl phthalate is 1:0.005:0.001:0.03;

[0044] (b) mixing the treated inorganic scattering particles and the organic matrix material, and mechanically stirring the mixed material to uniformly mix the inorganic scattering particles and the organic matrix material; the inorganic scattering particles account for 5% by weight in the mixed material;

[0045] (c) Extrude, mix, wire-draw and pelletize the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com