Anti-leakage structure of water storage container

A water storage container and anti-leakage technology, which is applied to building components, chemical instruments and methods, and large-capacity bulk material storage, etc., can solve problems such as waterproof membrane rupture, space occupation, and waterproof membrane loss, so as to prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the embodiments of the present invention in more detail in conjunction with the drawings, so that any skilled person who is familiar with this technology can implement them after studying this specification.

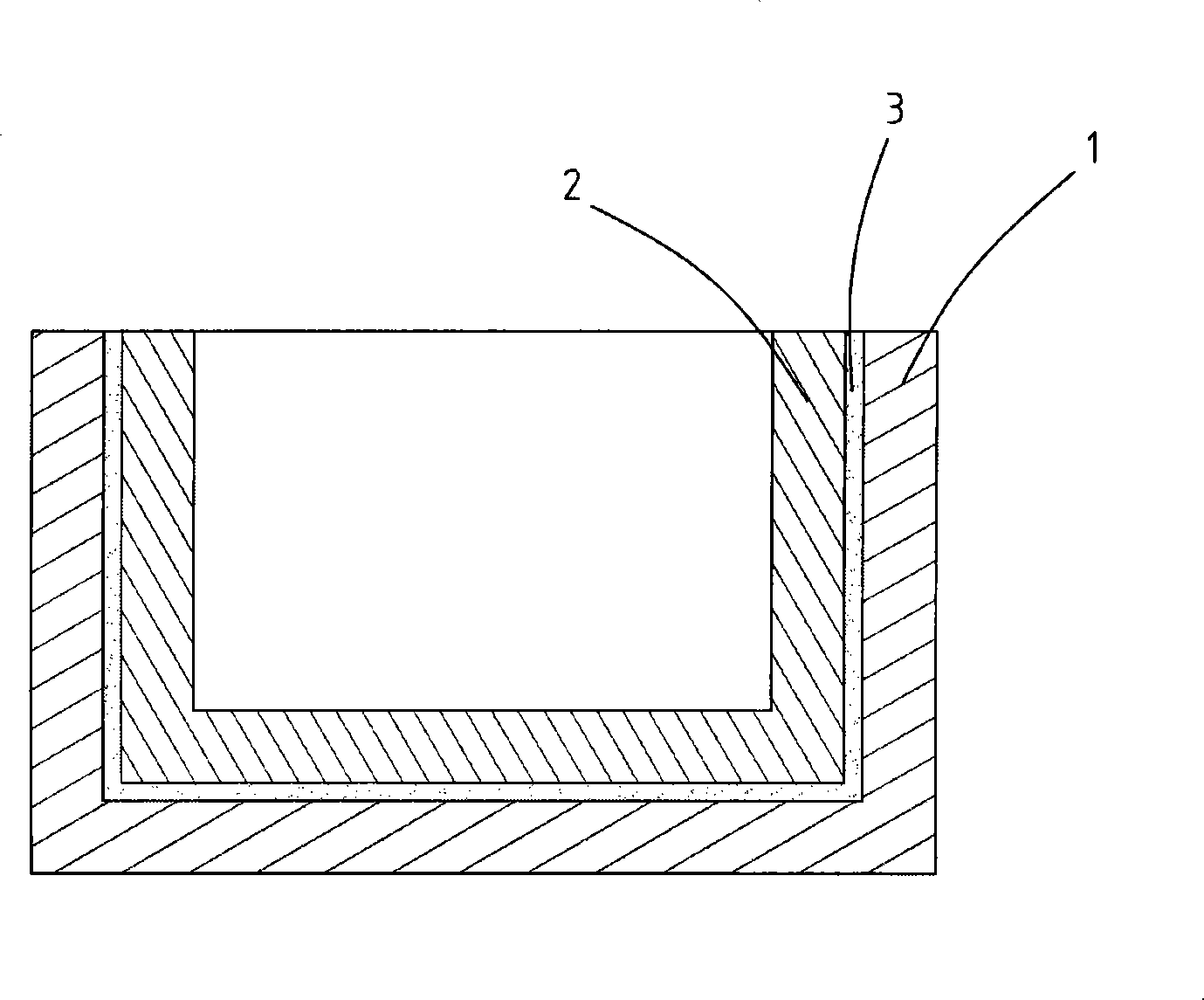

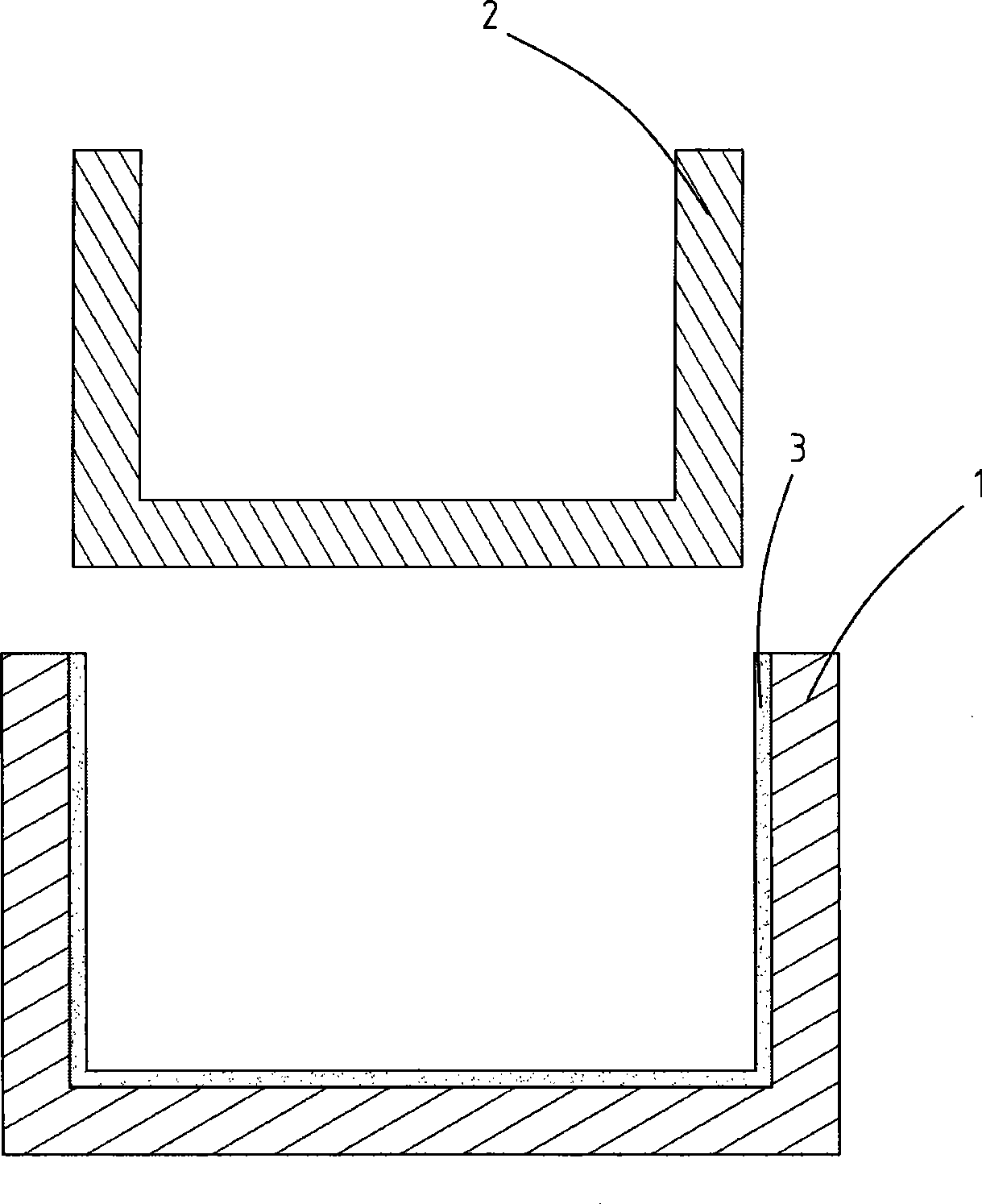

[0021] Such as figure 1 As shown, the preferred embodiment of the anti-leakage structure of the water storage container of the present invention includes an outer body 1, an inner body 2, and a waterproof powder layer 3, and the waterproof powder layer 3 is located on the inner body 2 Between the outer body 1 and the inner body 2, the inner body 2 is used to directly contain water, and the waterproof powder layer 3 is used as a structural layer to prevent water from seeping from the inner body 2 to the outer body 1; the outer body 1 Both the body and the inner body 2 can be of concrete structure or brick structure; or the outer body 1 is of concrete structure, while the inner body 2 is of brick structure; or the outer body 1 is of brick str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com