Preparation for silicon substrate on isolator

An insulator, silicon substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult corrosion control, poor silicon uniformity on the top layer of SOI substrate, etc., to improve the corrosion selection ratio, maintain activity, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the method for preparing a silicon-on-insulator substrate provided by the present invention will be described in detail below with reference to the accompanying drawings.

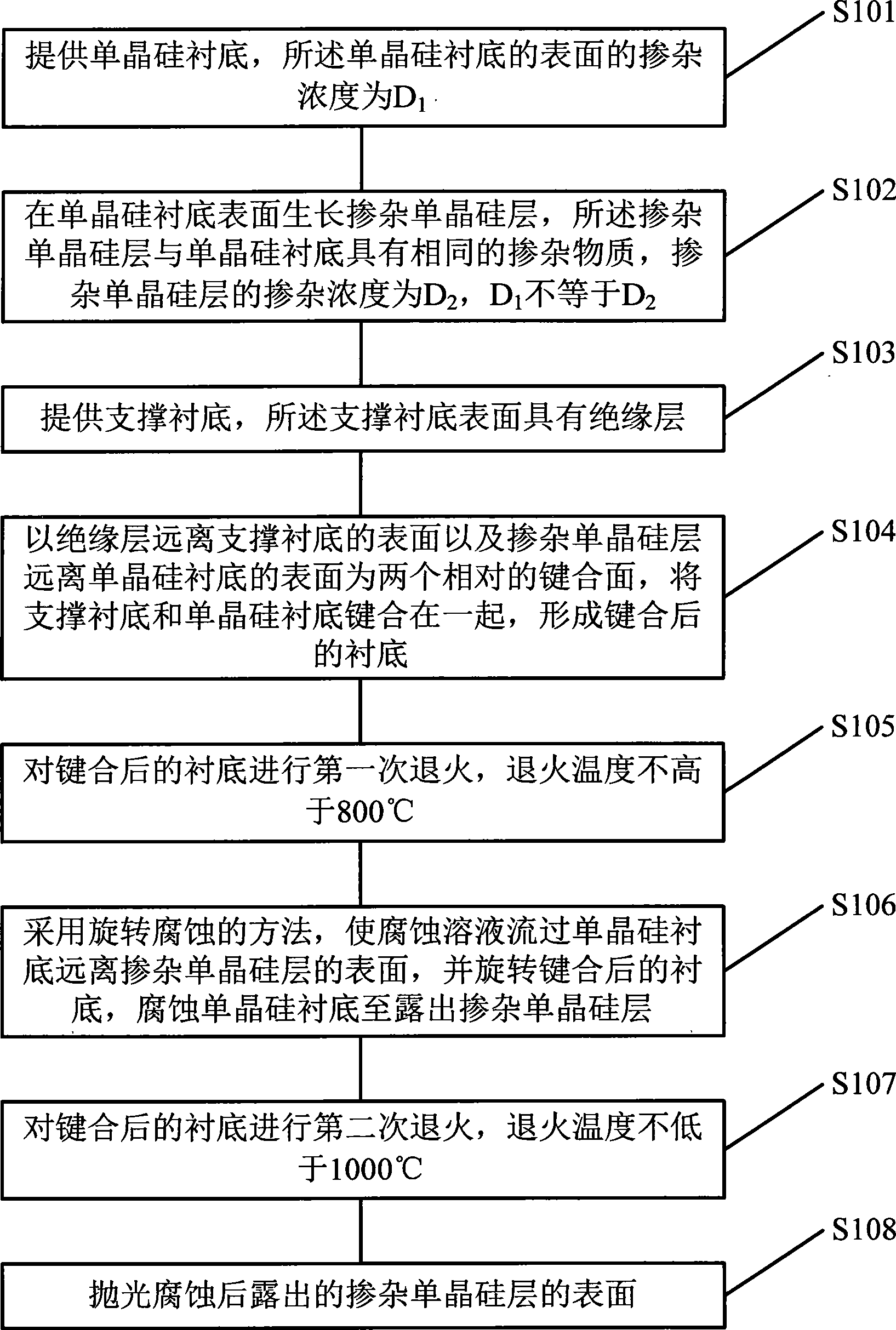

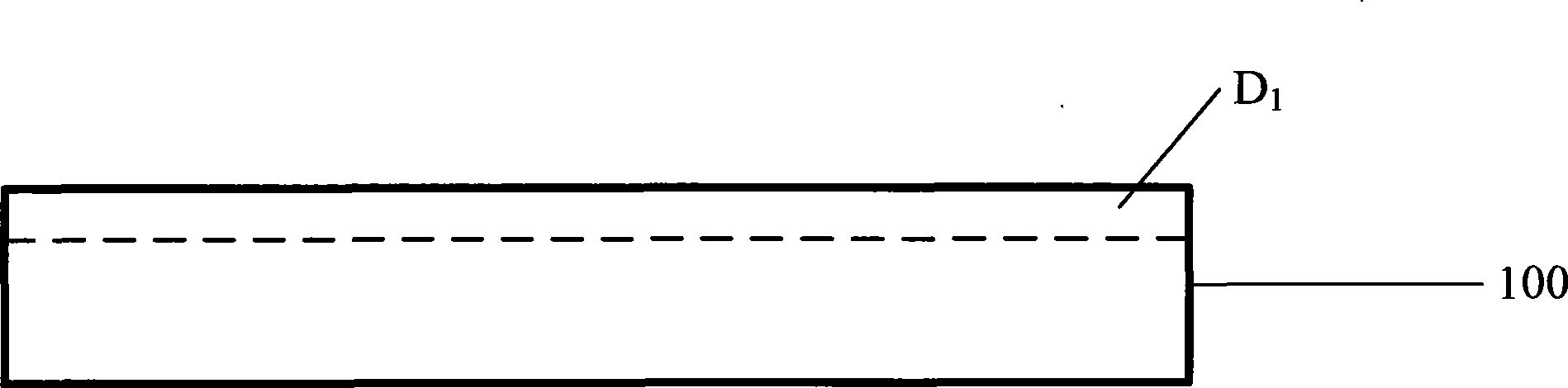

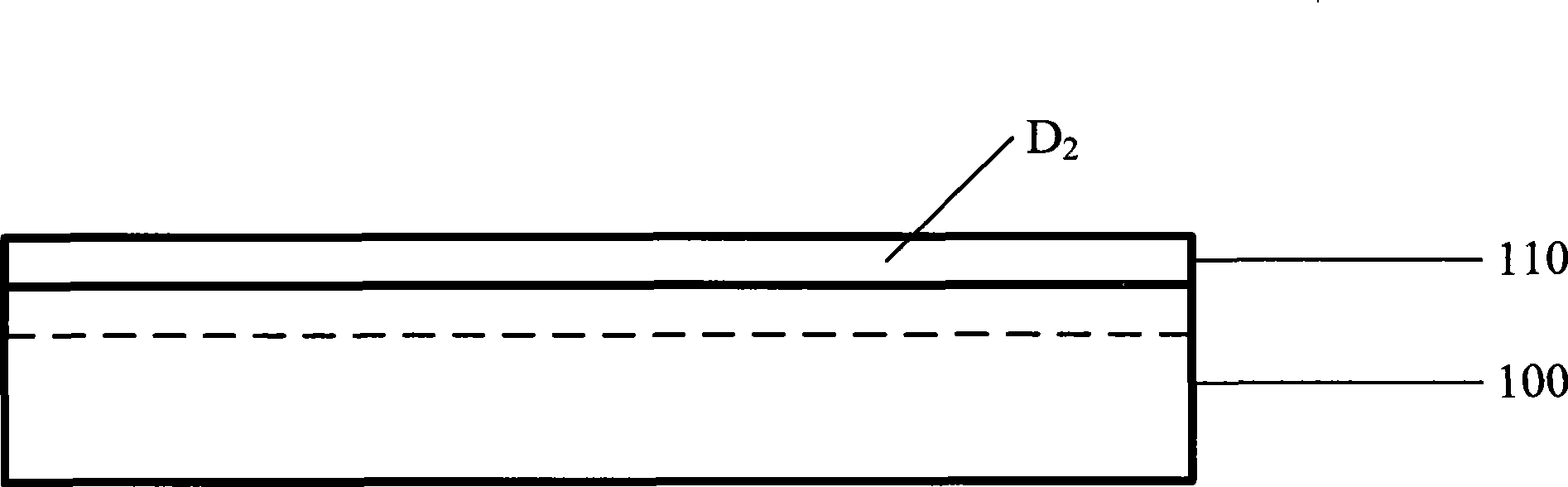

[0021] First, the first specific implementation of the method for preparing a silicon-on-insulator substrate provided by the present invention is given. figure 1 Shown is the flow chart of the implementation steps of this specific embodiment, including the following steps: Step S101, providing a single crystal silicon substrate, the doping concentration of the surface of the single crystal silicon substrate is D 1 ; Step S102, growing a doped single crystal silicon layer on the surface of the single crystal silicon substrate, the doped single crystal silicon layer has the same doping substance as the single crystal silicon substrate, and the doping concentration of the doped single crystal silicon layer for D 2 ,D 1 not equal to D 2; Step S103, providing a support su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com