Color crystal and method for coloring plastic using the same

A color crystal and plastic technology, applied in the field of polymer material coloring, to achieve the effects of improved uniformity, easy inventory, and inventory control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

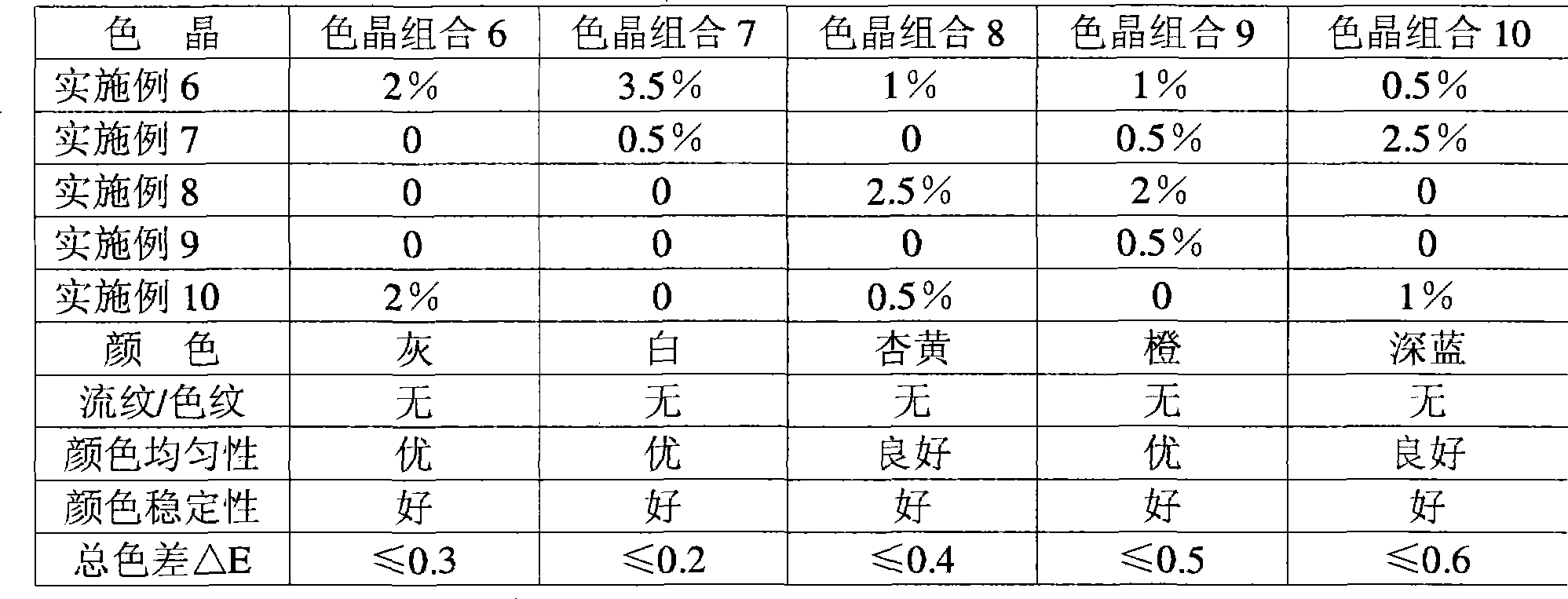

Examples

Embodiment Construction

[0027] Examples 1-5 are the formulations of ABS color crystals, see Table 1. Using a twin-screw extruder to melt and knead under the condition of 160-200°C, press into tablets with a three-roller machine, and then break into color crystals.

[0028] Table 1 ABS color crystal formula

[0029] Material Example 1 Example 2 Example 3 Example 4 Example 5 ABS 40 60 30 40 50 Zinc stearate 1 0 1 0.5 1 polyethylene wax 3 2 1.5 5 7 Oxidized polyethylene wax 2 1 0.5 0 3 super dispersant 2 1 4 5 3 Titanium dioxide 40 0 0 0 0 ultramarine 0 10 0 0 0 Titanium Yellow 0 0 15 0 0 Phthalo green 0 0 0 8 0 carbon black 0 0 0 0 5 Antioxidant 1076 0.2 0.2 0.2 0.2 0.2 Antioxidant 168 0.4 0.4 0.4 0.4 0.4 calcium carbonate 9.4 0 0 40.9 30.4 Barium sulfate 0 34.6 0 0 0 talcum powder 0 0 59.6 0 0 color

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com