Solar battery sealing material

A technology for solar cells and sealing materials, applied in the field of solar cell sealing materials, can solve the problems of easy exudation of organic peroxides, decreased productivity, difficult to carry out, etc., achieves excellent adhesion, stable quality, and avoids processing problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

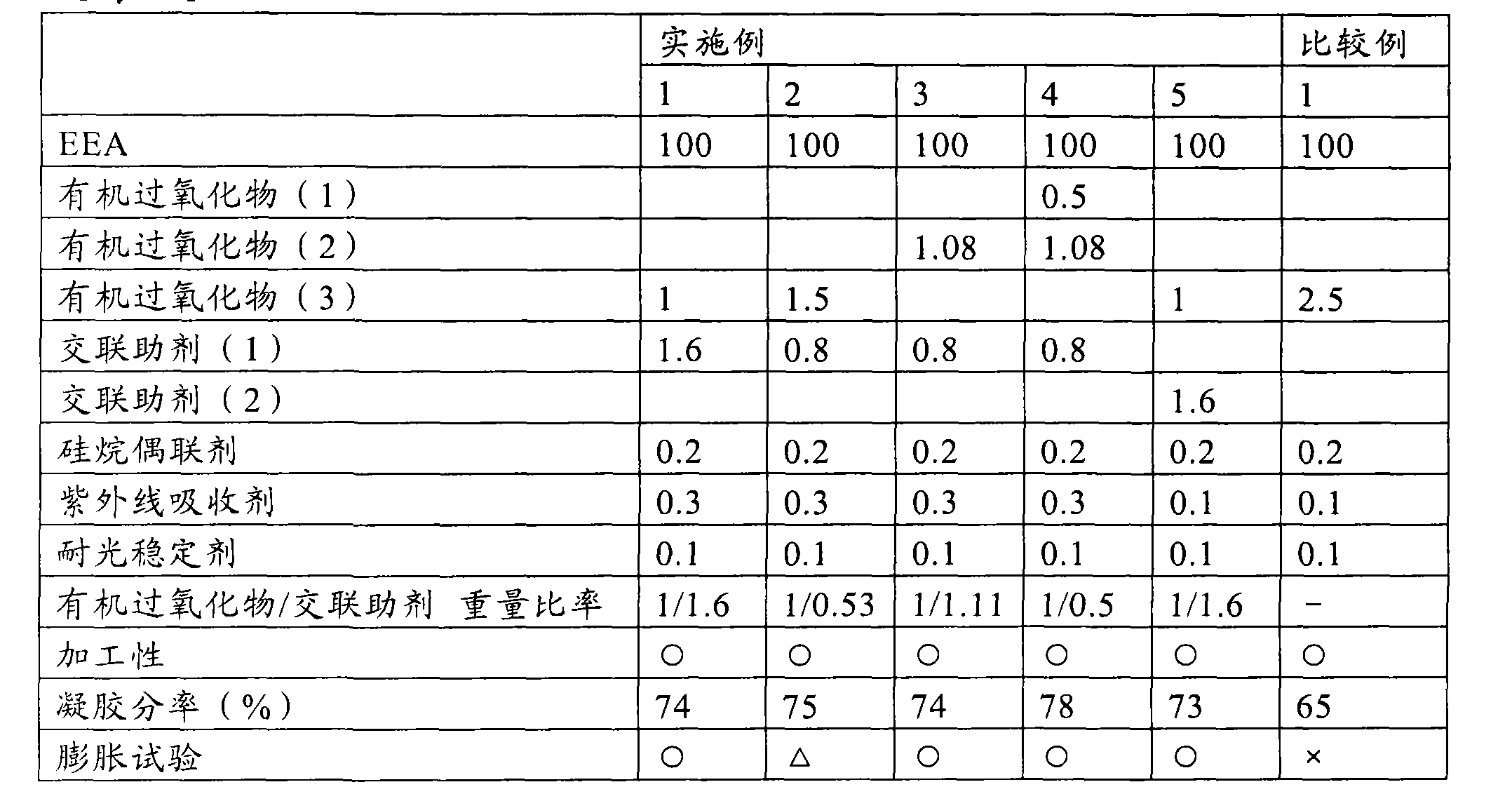

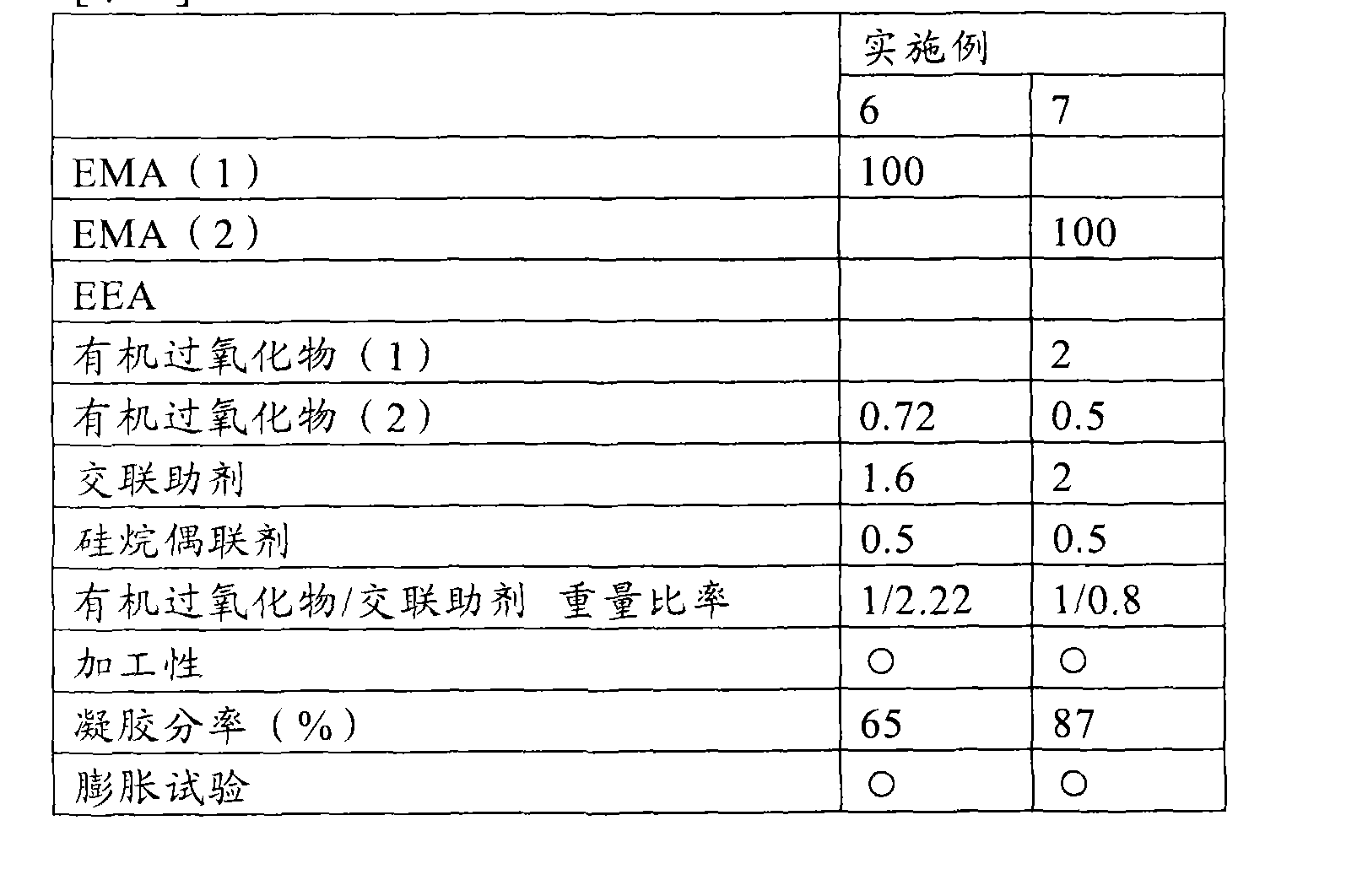

Embodiment 1

[0059] Mix the above-mentioned ethylene ethyl acrylate copolymer (EEA), organic peroxide (3), crosslinking aid (1), silane coupling agent, ultraviolet absorber and light-resistant stabilizer according to the ratio shown in Table 1 in advance, After 3 hours, a sheet having a thickness of 0.6 mm was produced at a processing temperature of 100° C. using a T-die extruder (40 mm in diameter, full flight screw, CR=2.6, L / D=26). The above-mentioned various evaluations were performed using this sheet. The results are shown in Table 1.

Embodiment 2

[0061] Except for changing the usage-amount of the organic peroxide (3) and crosslinking auxiliary agent (1) as shown in Table 1, sheet molding was performed similarly to Example 1, and it evaluated. The results are shown in Table 1.

Embodiment 3

[0063] Sheet molding was performed in the same manner as in Example 2 except that the organic peroxide (2) was used instead of the organic peroxide (3) at the ratio shown in Table 1, and this was evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com