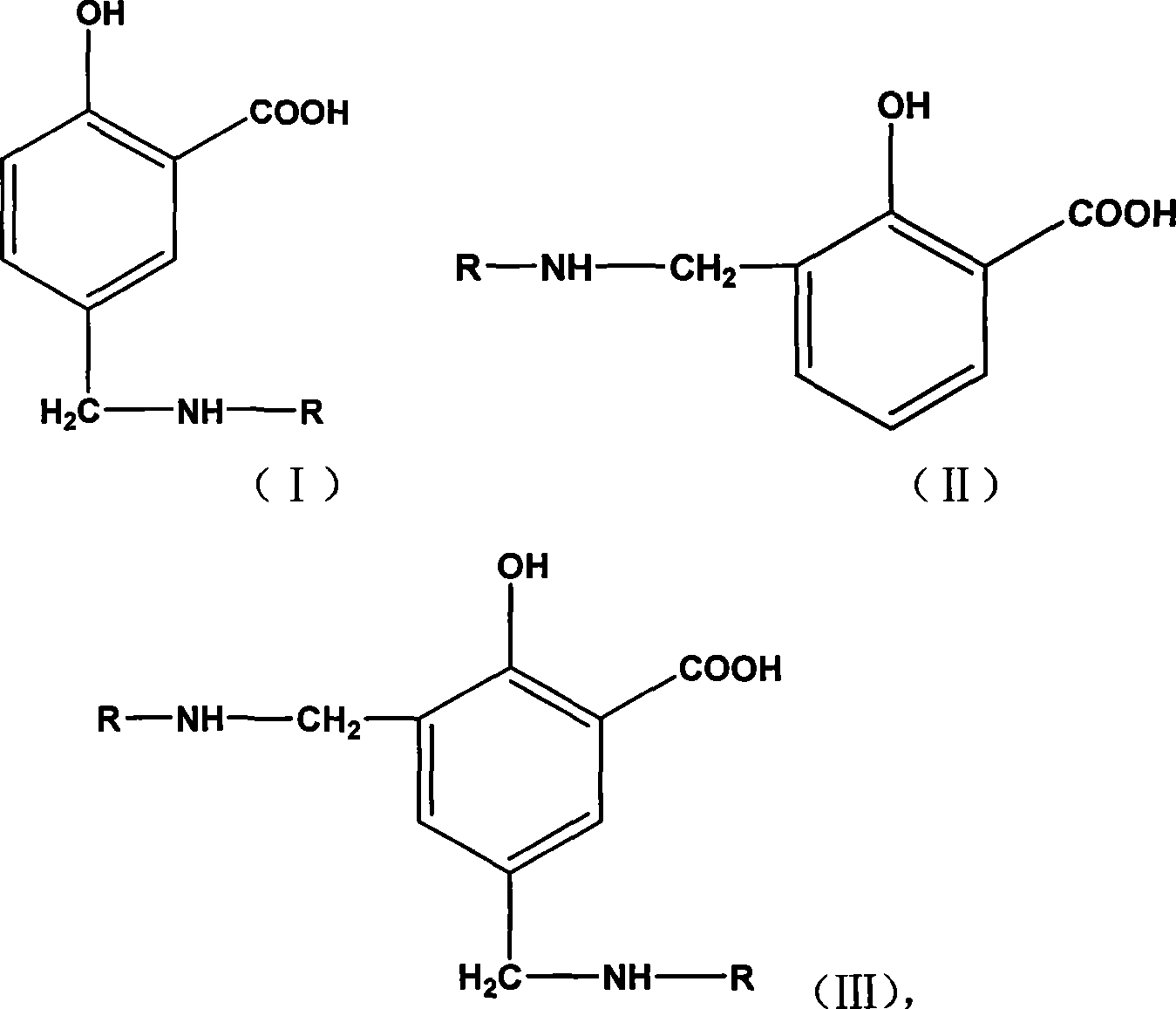

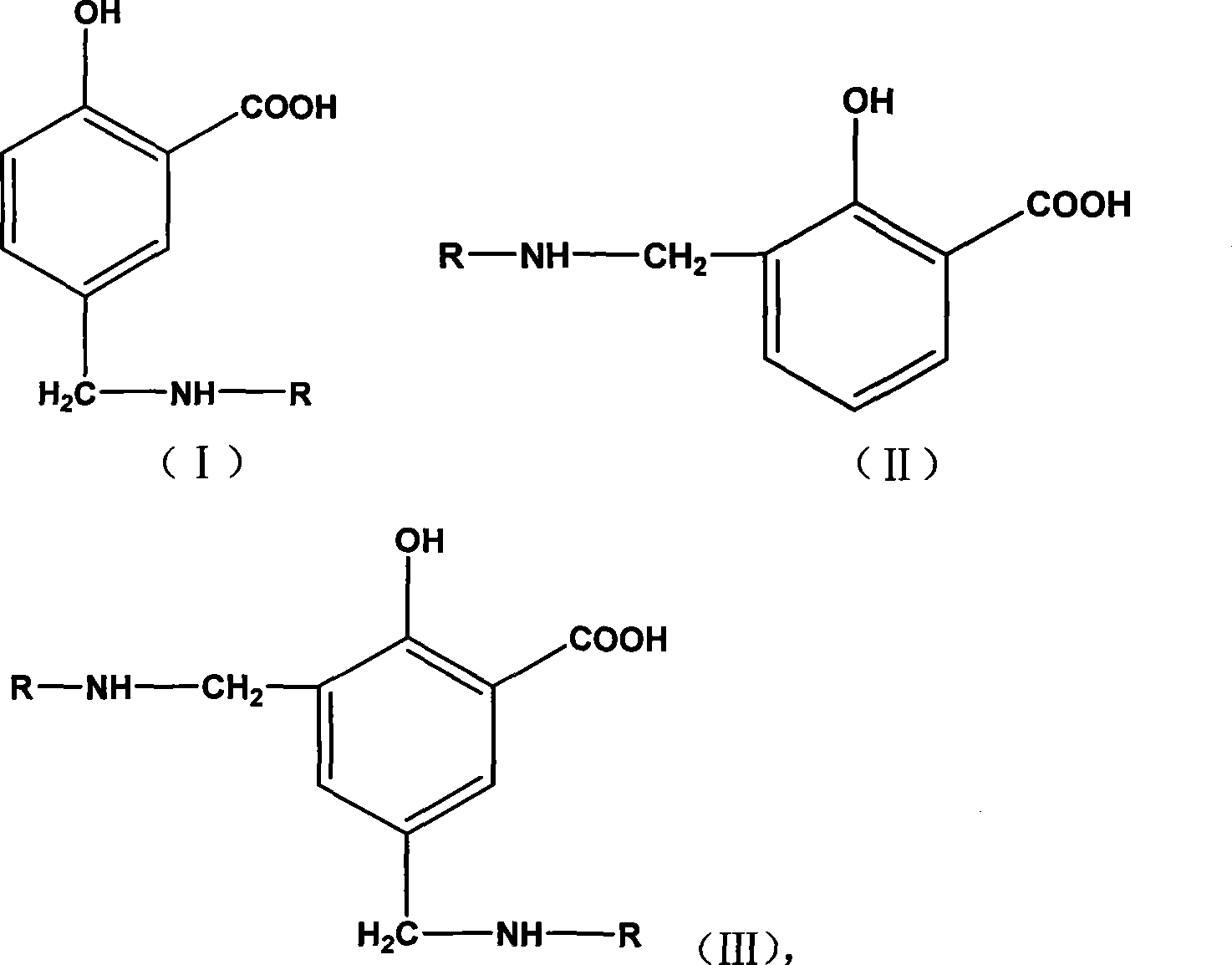

Dispersant for salicylic acid derivatives pigments and preparation method and use thereof

A technology of salicylic acid derivatives and dispersants, which is applied in the field of dispersants for salicylic acid derivative pigments and its preparation, can solve problems such as limitation, improve coloring strength and transparency, be environmentally friendly, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

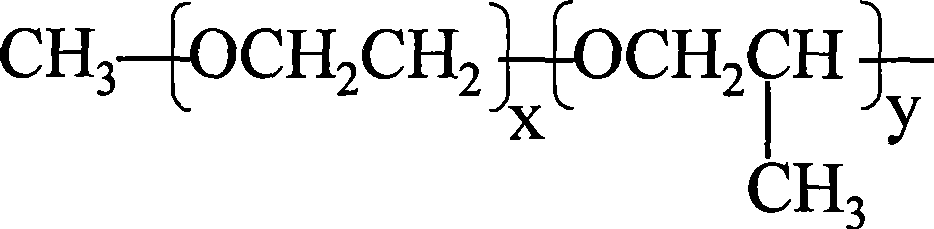

[0034] Dispersant A: Add B-200 (lipophilic polyether primary amine with a product name of Surfonamine B-200) with a molecular weight of 2000 to a 250ml three-necked flask, and the ratio of propylene oxide / ethylene oxide (PO / EO) is 29 / 6, Huntsman Corp.) 12 parts, salicylic acid (purity is 99.2%) 0.83 parts, stir evenly at 50 ℃, then dropwise add formaldehyde solution (37%) 0.5 part, heat up to 90 ℃ and stir for two hours, then Then the temperature was raised to 120° C. and stirred for two hours. 1 H-NMR shows a chemical shift of 3.8-3.9, which is a significant sign of Mannich base methylene, FT-IR shows that the primary amino group completely disappears, 3610mm -1 (—NH 2 ) peak disappears, resulting in a 3454mm -1 Absorption peak at (-NH-). The resulting amber liquid was used for evaluation of the pigment properties of Example 2.

[0035] Dispersant B: The method steps are the same as above, except that the primary amine B-200 used is changed to L-207 (hydrophilic polyethe...

Embodiment 2

[0037] 1 part of P.Y.83 pigment (containing 4% by weight of dispersant A) is added to 8 parts of solvent-based ink binder, which contains nitrocellulose, plus 8 parts of glass beads with a diameter of 2-3mm. The mixture was shaken on an oscillating mixer for 30 minutes to obtain a thick ink. Dilute and vibrate the obtained thick ink with binder and corresponding solvent to obtain light color ink. Compared with P.Y.83 without additives, which is formulated in the same way, the tinting strength of the inks containing additives is increased by about 5%, and they are more transparent and have lower viscosity. It shows that after adding dispersant A, the dispersibility of the pigment is improved.

Embodiment 3

[0039] 9.6 parts of P.R.57:1 pigments (containing 4% by weight of dispersant B) were added to 17.76 parts of water-based ink binders containing acrylic acid (trade name "Joncryl 61", S.C.Johnson.Co.) and Add 40 parts of glass beads with a diameter of 2-2.5 mm. The mixture was shaken on an oscillating mixer for 60 minutes to obtain a thick ink. Dilute and vibrate the obtained thick ink with pre-prepared white ink to obtain light color ink. Compared with P.R.57:1 that does not contain additives, the coloring strength of the ink is increased by about 11%, and the viscosity of the thick ink is reduced. It shows that after adding dispersant B, the dispersibility of the pigment is improved.

[0040] With salicylic acid as the parent, —CH 2—NH—is a bridging group, and the polyalkoxy structure is a branched dispersant, which can be used in solvent-based or water-based ink systems respectively. The test results show that compared with the pigment without this kind of salicylic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com