Method for treating ammonia nitrogen waste water containing vanadium using natural clinoptilolite

A technology of clinoptilolite and ammonia nitrogen wastewater, which is applied in the field of treating vanadium-containing ammonia nitrogen wastewater and wastewater by using natural clinoptilolite, can solve the problems of complicated process, high operating cost, and low treatment efficiency of ammonia nitrogen wastewater treatment methods, and achieve the goal of equipment The effect of simplicity, low processing cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The ammonia nitrogen concentration of the treated vanadium-containing ammonia nitrogen wastewater is 20mg / L, pH=5, and temperature is 20°C.

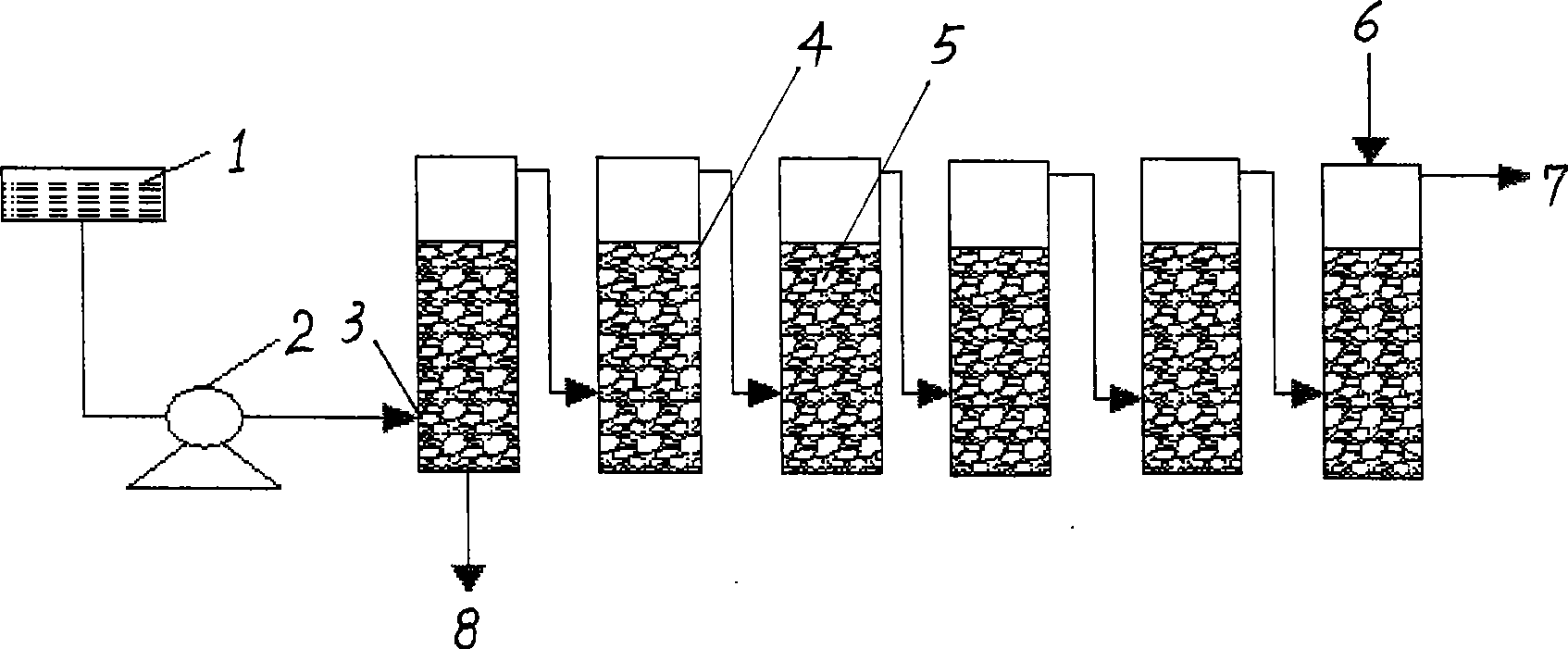

[0033] 1. Wastewater treatment: Pass the vanadium-containing ammonia-nitrogen wastewater through the ion exchange column equipped with 50g of natural clinoptilolite with a particle size of 0.5-2mm at a flow rate of 30ml / min. The final concentration of ammonia nitrogen in the effluent is 4mg / L, and the installed The ion exchange column with clinoptilolite adsorbs ammonia nitrogen to the breakthrough point;

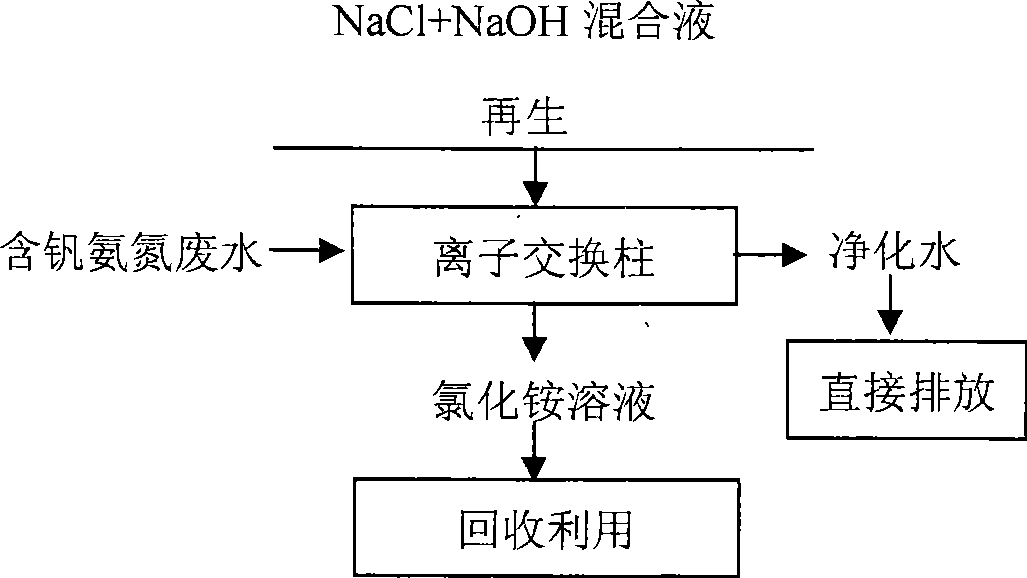

[0034] 2. Clinoptilolite regeneration: After NaCl and NaOH are prepared into a mixed solution with a concentration of 5.0g / L at a mass ratio of 3:7, the mixed solution is used as a regenerating agent for clinoptilolite, and the flow rate is 15ml / min. The flow rate passes through an ion exchange column equipped with 50 g of clinoptilolite that has adsorbed ammonia nitrogen to reach the breakthrough point, and repeats the passage...

Embodiment 2

[0037] The ammonia nitrogen concentration of the treated vanadium-containing ammonia nitrogen wastewater is 100mg / L, pH=4, and temperature is 25°C.

[0038] 1. Wastewater treatment: pass the vanadium-containing ammonia-nitrogen wastewater through the ion exchange column equipped with 100g of natural clinoptilolite with a particle size of 0.5-2mm at a flow rate of 80ml / min. The ion exchange column of zeolite adsorbs ammonia nitrogen to the breakthrough point;

[0039] 2. Clinoptilolite regeneration: After NaCl and NaOH are prepared into a mixed solution with a concentration of 5.0g / L according to the mass ratio of 4:8, the mixed solution is used as the regeneration agent of clinoptilolite, and the flow rate is 10ml / min. The flow rate passes through an ion-exchange column equipped with 100 g of clinoptilolite that has adsorbed ammonia nitrogen to reach the breakthrough point, repeats the passage 3 times, and the time for each passage is 4 hours to obtain the filtrate of ammonium...

Embodiment 3

[0042] The ammonia nitrogen concentration of the treated vanadium-containing ammonia nitrogen wastewater is 350mg / L, pH=5, and temperature is 22°C.

[0043] 1. Wastewater treatment: Pass the vanadium-containing ammonia-nitrogen wastewater through the ion exchange column equipped with 150g of natural clinoptilolite with a particle size of 0.5-2mm at a flow rate of 60ml / min. The ion exchange column of zeolite adsorbs ammonia nitrogen to the breakthrough point;

[0044] 2. Clinoptilolite regeneration: After NaCl and NaOH are prepared into a mixed solution with a concentration of 5.0g / L according to the mass ratio of 5:9, the mixed solution is used as the regeneration agent of clinoptilolite, and the flow rate is 20ml / min. The flow rate passes through an ion exchange column equipped with 150 g of clinoptilolite that has adsorbed ammonia nitrogen to reach the breakthrough point, repeats the passage twice, and the time for each passage is 3 hours to obtain the filtrate of ammonium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com