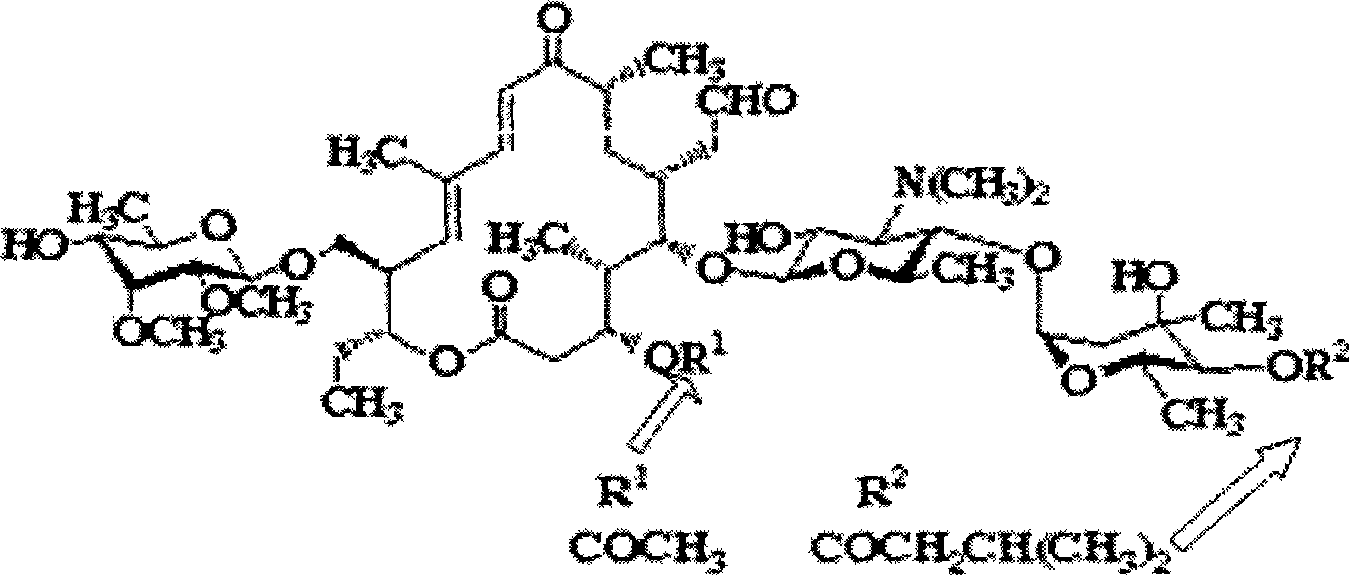

Purification method of super tylosin

A technology of super tylosin and purification method, which can be applied in microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., and can solve the problems of high cost, easy environmental pollution, and high operation toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After about 170 hours of fermentation and cultivation of super tylosin transforming bacteria in the fermenter, 50 tons of super tylosin fermentation liquid was obtained, and diluted with water to 70 tons, and the temperature of the fermentation liquid was lowered to 20°C; Add 6mol / L hydrochloric acid solution, adjust the pH of the fermentation broth to 2, and stir for 3 hours. Sampling for HPLC detection showed that the titer was 4572u / ml, and the dissolution rate of super tylosin was 96%. Plate and frame filtration, and the filtrate enters the crystallization tank. Raise the temperature of the primary acid-soluble filtrate to 40°C, add 4mol / L potassium hydroxide solution, slowly adjust the pH value to 7.5, and let it stand for 4 hours to produce super tylosin crystals. The serum titer is 82u / ml. The primary crystals were dissolved in water, the temperature of the solution was lowered to 20°C, and 6 mol / L hydrochloric acid solution was added to dissolve it all, and th...

Embodiment 2

[0022] After about 170 hours of fermentation and cultivation of the super tylosin transformed bacteria in the fermenter, 50 tons of super tylosin fermentation broth was obtained, diluted with water to 70 tons, and the temperature of the fermentation broth was lowered to 25°C; 4mol / L sulfuric acid solution, adjust the pH of the fermentation broth to 3.8, and stir for 1 hour. Sampling for HPLC detection showed that the titer was 4821u / ml, and the dissolution rate of super tylosin was 97%. Plate and frame filtration, and the filtrate enters the crystallization tank. Raise the temperature of the primary acid-soluble filtrate to 40°C, add 4mol / L sodium carbonate solution, slowly adjust the pH value to 8, and let it stand for 8 hours to produce super tylosin crystals, obtain the primary crystals by plate and frame filtration, and detect the supernatant The titer of the solution is 80u / ml. The primary crystals were dissolved in water, the temperature of the solution was lowered to ...

Embodiment 3

[0024] After about 170 hours of fermentation and cultivation of the super tylosin transformed bacteria in the fermenter, 50 tons of super tylosin fermentation liquid was obtained, and diluted to 70 tons with water, and the temperature of the fermentation liquid was lowered to 30°C; Add 8mol / L tartaric acid solution, adjust the pH of the fermentation broth to 5.5, and stir for 2 hours. Sampling for HPLC detection showed that the titer was 4427u / ml, and the dissolution rate of super tylosin was 95%. Plate and frame filtration, and the filtrate enters the crystallization tank. Raise the temperature of the primary acid-soluble filtrate to 60°C, add 6mol / L sodium bicarbonate solution, slowly adjust the pH value to 10, and let it stand for 6 hours to produce super tylosin crystals, and obtain the primary crystals by plate and frame filtration. The serum titer was 79u / ml. The primary crystals were dissolved in water, the temperature of the solution was lowered to 35°C, and 8 mol / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com