Thin-film diode, double scanning diode array substrate and LCD board

A technology of thin film diodes and diode arrays, applied in optics, instruments, electrical components, etc., can solve the problems of deterioration of electrical characteristics, current breakdown, and film damage of thin film diodes 132

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

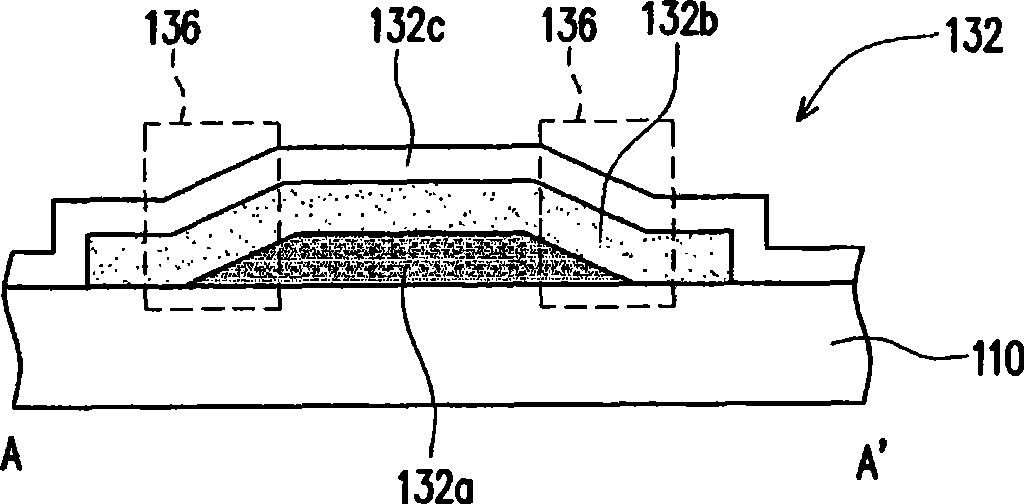

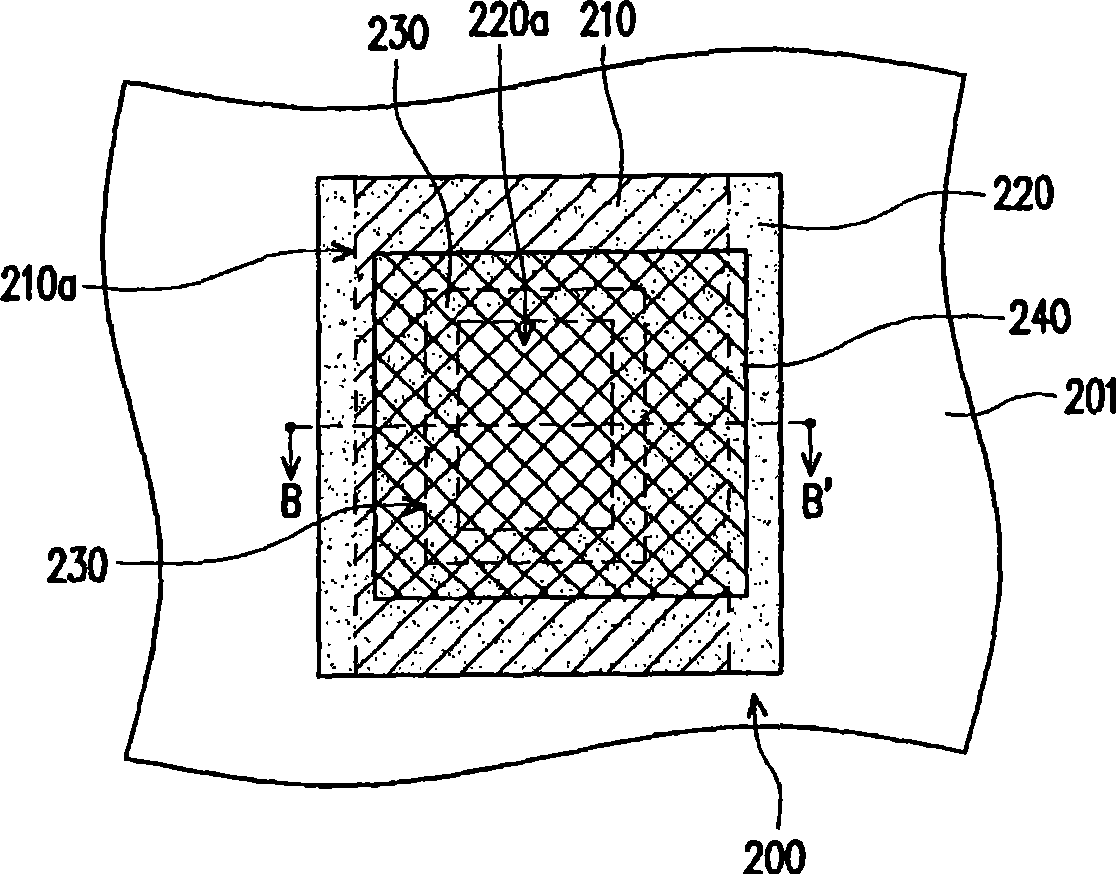

[0060] Figure 2A is a top view of a thin film diode according to an embodiment of the present invention, and Figure 2B for along Figure 2A The schematic cross-sectional view of the thin film diode shown by the section line BB'. Please also refer to Figure 2A and Figure 2B , the thin film diode 200 of this embodiment is suitable for disposing on a substrate 201 , wherein the thin film diode 200 includes a first electrode 210 , an insulating layer 220 , an active layer 230 and a second electrode 240 . The first electrode 210 is disposed on the substrate 201 . In this embodiment, the material of the substrate 201 can be selected from inorganic transparent materials (such as: glass, quartz, or other appropriate materials) or organic transparent materials (such as: polyolefins, polyols, polyalcohols, polyesters, etc.) polymers, rubber, thermoplastic polymers, thermosetting polymers, polyaromatic hydrocarbons, polymethylmethacrylates, polycarbonates, or other suitable mate...

no. 2 example

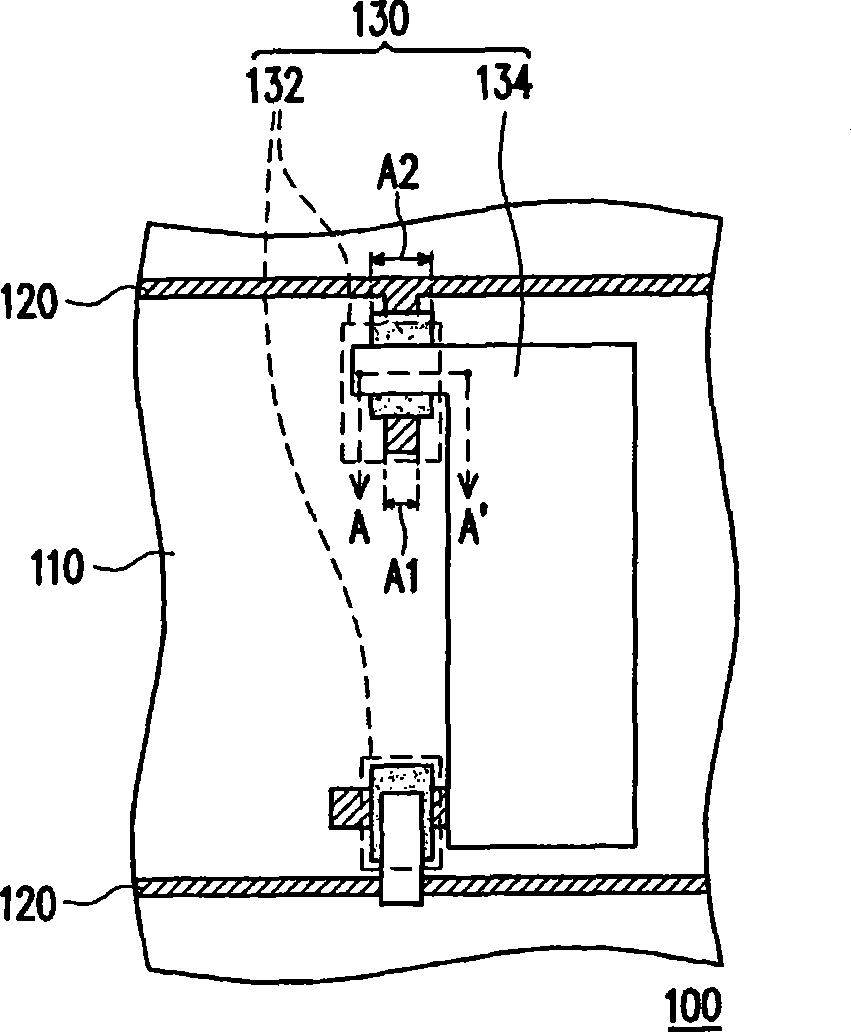

[0070] Figure 3A It is a schematic circuit diagram of a dual scanning diode array substrate according to an embodiment of the present invention, Figure 3B shown as Figure 3A The top view of the film layer in the region P1, while Figure 3C then along Figure 3B The cross-sectional schematic diagram shown by the section line CC'. Please also refer to Figure 3A , Figure 3B and Figure 3C , the dual scan diode array substrate 300 of this embodiment includes a substrate 310 , a plurality of scan lines 320 and a plurality of pixel units 330 . The scan lines 320 are disposed on the substrate 310 . The pixel units 330 are disposed on the substrate 310 , wherein each pixel unit 330 includes two thin film diodes 332 and a pixel electrode 334 . The pixel electrodes 334 are electrically connected to different scan lines 320 through the two thin film diodes 332 . Each thin film diode 332 adopts the film layer design of the above thin film diode 200 , and the same components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com