Preparation method of high pure succinate surfactants for paper manufacturing industry

A technology of surfactants and succinates, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problem of poor purity of dialkyl succinate sodium sulfonate surfactants, complex product components, and application problems. Limitation of scope and other issues, to achieve the effect of reducing production costs, less by-products, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

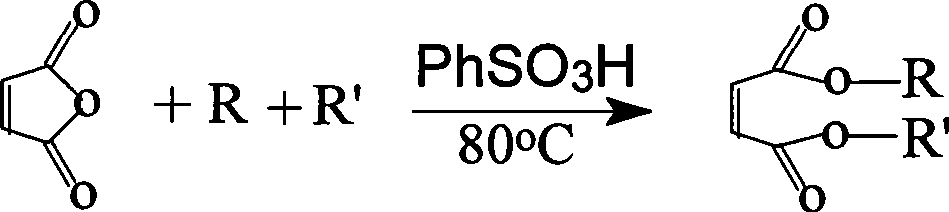

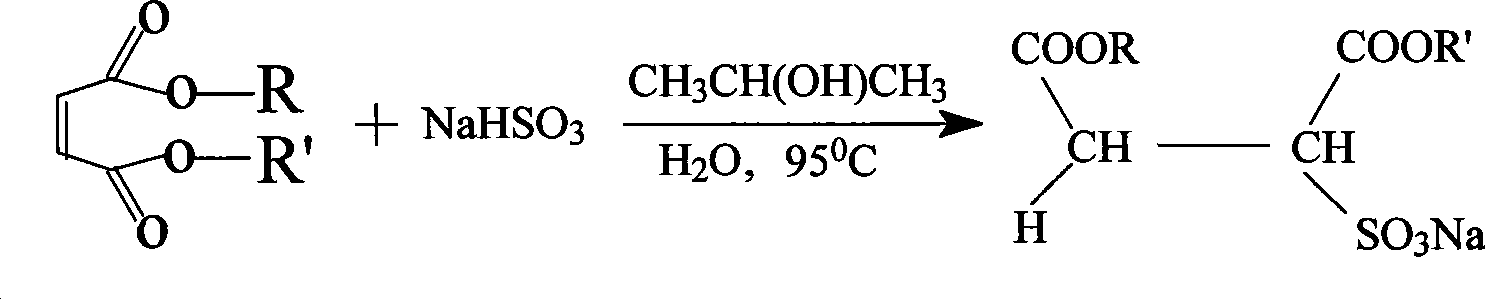

Method used

Image

Examples

Embodiment 1

[0023] (1) Add maleic anhydride and isooctyl alcohol with a molar ratio of 1:2 in the reactor, add the catalyst p-toluenesulfonic acid of 0.3% of the total molar amount, and equip a condenser tube, a temperature control device, and a water separator, Heated to 130°C and kept at this temperature for 5 hours, then cooled to room temperature to obtain a light yellow viscous liquid.

[0024] (2) Washing the obtained first step product with potassium carbonate aqueous solution and sodium chloride aqueous solution three times respectively to obtain diisooctyl succinate. Its appearance is light yellow liquid, the average yield is 94%, and the refractive index is 1.4543.

[0025] (3) Add the washed and separated product into the reaction kettle, then add sodium bisulfite and esterification product with a molar ratio of 1:1 and water with a total molar weight of 15% of sodium bisulfite, and equip a condenser tube and a mechanical Stir and heat to reflux at 100°C for 6 hours. Then coo...

Embodiment 2

[0027] (1) Add maleic anhydride and n-dodecyl alcohol in the reaction kettle at a molar ratio of 1:2, add 0.5% p-toluenesulfonic acid as a catalyst, equip a condenser, a temperature control device, and a water separator, and heat to 165 °C and maintained at this temperature for 5 hours, then cooled to room temperature.

[0028] (2) Add the product of the first step in the reaction kettle, then add sodium bisulfite and esterification product and water with a total molar weight of 15% of sodium bisulfite in a molar ratio of 1:1, add a condenser tube and mechanical stirring, Heat to reflux at 110°C for 6 hours. When the solution is cooled to about 50°C, add isopropanol to the solution and stir slightly.

Embodiment 3

[0030](1) Add maleic anhydride and n-tetradecyl alcohol in a molar ratio of 1:2 into the reactor, add 0.5% p-toluenesulfonic acid as a catalyst, and equip with a condenser, temperature control device, and water separator. Heat to 190°C and hold at this temperature for 5 hours, then cool to room temperature.

[0031] (2) Add the product of the first step in the reaction kettle, then add sodium bisulfite and esterification product and water with a total molar weight of 15% of sodium bisulfite in a molar ratio of 1:1, add a condenser tube and mechanical stirring, Heat to reflux at 95°C for 6 hours. When the solution is cooled to about 50°C, add isopropanol to the solution and stir slightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com