Method for preparing acrylic acid-grafted polypropylene by supercritical carbon dioxide

A technology of acrylic acid grafting and carbon dioxide, which is applied in the production of bulk chemicals, textiles and papermaking, fiber treatment, etc., can solve the limitations of the application field of acrylic acid grafted polypropylene, it is difficult to meet the application of adhesives and compatibilizers, and there is no need to consider crosslinking problems and other problems, achieve broad industrial application prospects, improve grafting rate and selectivity, and achieve the effects of solvent-free recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Use polypropylene granules, DCP and AA as raw materials, add them into a stainless steel high-pressure reactor equipped with stirring and pressure sensors at a weight ratio of PP / AA / DCP=100 / 10.5 / 0.5, and use CO 2 After the air in the kettle was purged clean, an appropriate amount of CO was introduced. 2 ; Swell at 80°C and 10.8MPa for 1 hour; then, heat up to 140°C, corresponding to a pressure of 15MPa, at this time, DCP thermally decomposes to initiate a free radical grafting reaction; after 4 hours of reaction, the CO in the kettle 2 Empty and take out the crude product of the graft PP-g-AA; finally, the crude product is extracted with absolute ethanol and degelated to obtain purified PP-g-AA.

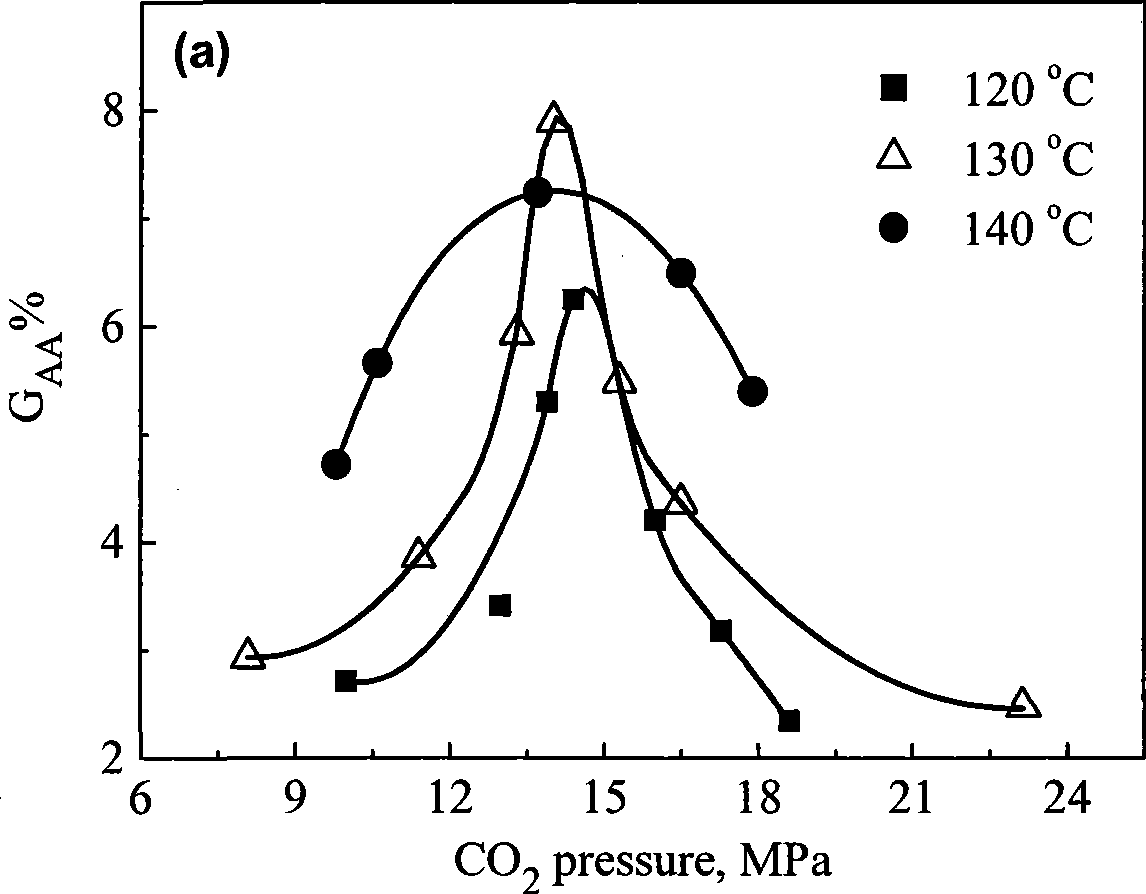

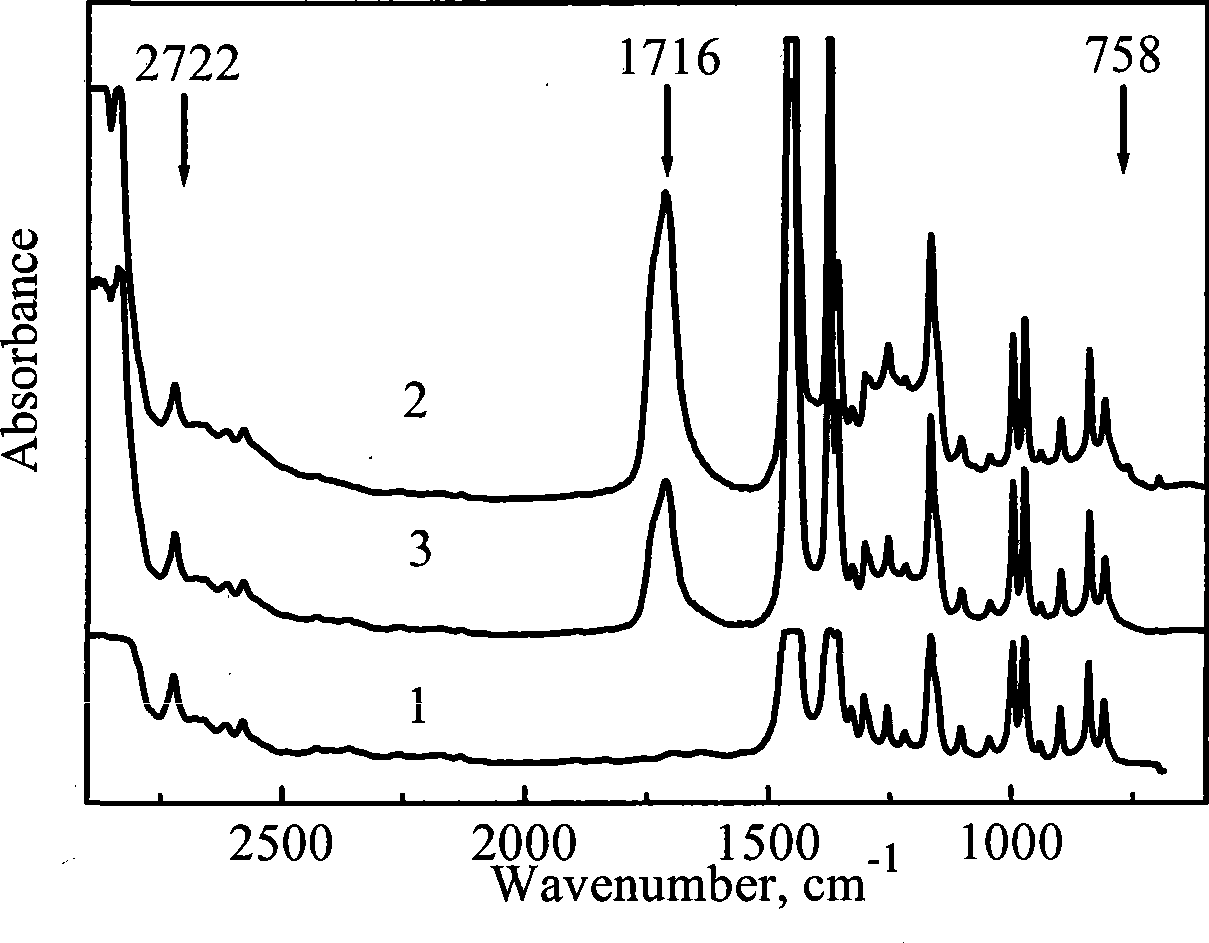

[0059] The samples of blank PP, PP-g-AA before and after purification were measured after melting and pressing, and their infrared spectra corresponded to image 3 Curves 1-3 in. It can be seen from the figure that both curve 2 and curve 3 are at 1716cm -1 There is a charac...

Embodiment 2

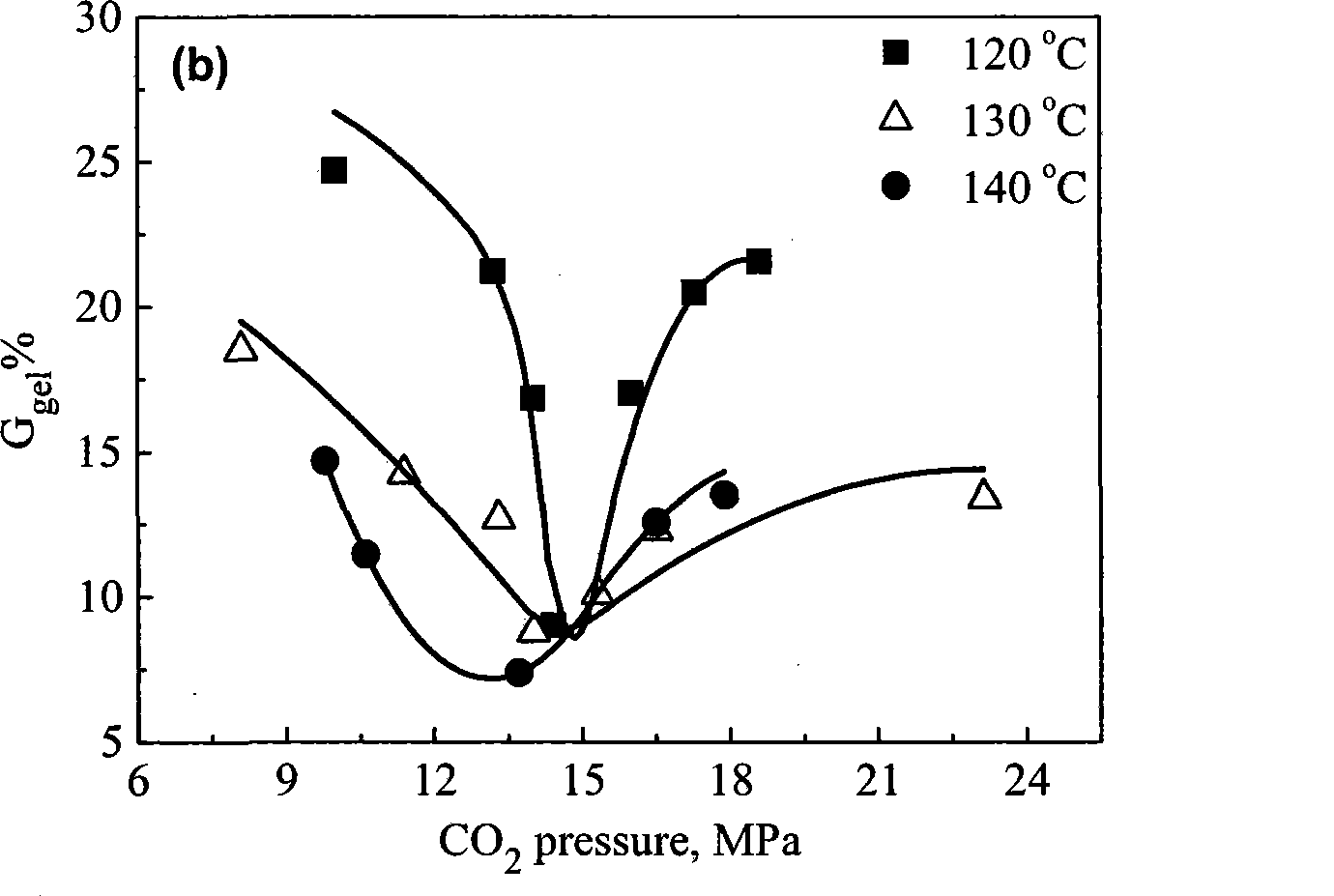

[0064] Use polypropylene powder, DCP and AA as raw materials, add them into a stainless steel high-pressure reactor equipped with stirring and pressure sensors according to the mass ratio PP / AA / DCP=100 / 10.5 / 0.5, and use CO 2 After the air in the kettle was purged clean, an appropriate amount of CO was introduced. 2 ; Swell at 80°C and 9.2MPa for 1 hour; then, the temperature is raised to 140°C, and the corresponding pressure is 13.2MPa. At this time, DCP is thermally decomposed to initiate a free radical grafting reaction; after 4 hours of reaction, the CO in the kettle 2 Evacuate and take out the crude product of grafted PP-g-AA; finally, perform relevant characterization after extraction with absolute ethanol and degelation. Gained sample graft rate is 7.2%, and gel rate is 7.3%, the temperature (T when sample weight loss 5wt%) 5% ) increased by 64°C, the complete decomposition temperature (T 100% ) increased by 72°C, the maximum decomposition rate temperature T pm Increa...

Embodiment 3

[0066] Use polypropylene powder, DCP and AA as raw materials, add them into a stainless steel high-pressure reactor equipped with stirring and pressure sensors according to the mass ratio PP / AA / DCP=100 / 10.5 / 0.5, and use CO 2 After the air in the kettle was purged clean, an appropriate amount of CO was introduced. 2 ; Swell at 80°C and 10.5MPa for 1 hour; then, heat up to 130°C, corresponding to a pressure of 14MPa, at this time, DCP thermally decomposes to initiate a free radical grafting reaction; after 4 hours of reaction, the CO in the kettle 2 Evacuate and take out the crude product of graft PP-g-AA; finally, obtain purified PP-g-AA after extraction with absolute ethanol and degelation. The obtained sample had a graft rate of 7.9% and a gel rate of 8.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com