Yellowing-resistant nitro white matt finish and preparation method thereof, use method

A technology of anti-yellowing and whiteness, which is applied to the device and coating of the surface coating liquid, which can solve the problems of poor yellowing resistance, yellowing and yellowing of white lacquer, and achieve improved gloss retention and surface Smooth, not easy to precipitate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] First prepare anti-yellowing nitro white matte finish paint of the present invention:

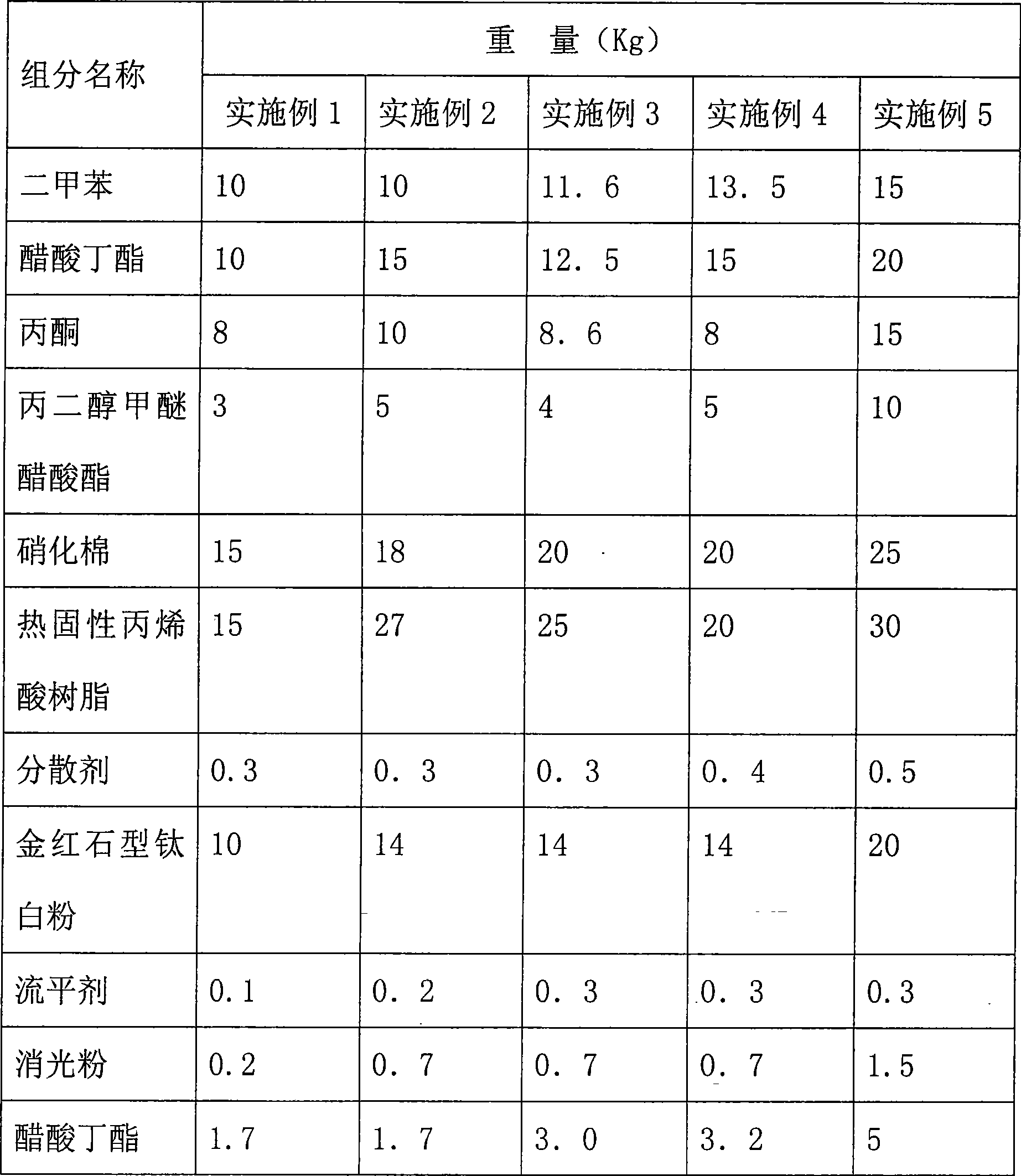

[0059] Get each component according to the weight listed in "Example 1" in Table 1, and the preparation method is as follows:

[0060] Step 1: Pre-dissolution of nitrocellulose: Take the mixed solvent of xylene, butyl acetate, acetone, and propylene glycol methyl ether acetate in the formula and add it to nitrocellulose, stir evenly at a low speed for 5-10 minutes until the nitrocellulose is completely dissolved, and set aside.

[0061] Step 2: According to the weight ratio, take the thermosetting acrylic resin and dispersant in the components and mix them evenly at low speed, then add rutile titanium dioxide, disperse at high speed for 20 minutes until the fineness is ≤20um, after adding matting powder, disperse at 1000RPM at high speed 15 minutes until fineness ≤ 25um, then add leveling agent and butyl acetate, disperse at medium speed for 10 minutes until uniform.

[0062] Step 3...

Embodiment 2

[0072] Prepare anti-yellowing nitro white matte finish paint of the present invention:

[0073] Get each component according to the weight listed in "Example 2" in Table 1, and the preparation method follows the steps below: Step 1: pre-dissolving of nitrocellulose: get xylene, butyl acetate, acetone, propylene glycol methyl ether acetate in the formula Add the mixed solvent to the nitrocellulose, stir evenly at low speed for 5-10 minutes until the nitrocellulose is completely dissolved, set aside.

[0074] Step 2: According to the weight ratio, take the thermosetting acrylic resin and dispersant in the components and mix them evenly at low speed, then add rutile titanium dioxide, disperse at high speed for 20 minutes until the fineness is ≤20um, after adding matting powder, disperse at 1000RPM at high speed 15 minutes until fineness ≤ 25um, then add leveling agent and butyl acetate, disperse at medium speed for 10 minutes until uniform.

[0075] Step 3: Add the pre-dissolved...

Embodiment 3

[0085] With the weight of each component listed in "Example 3" in Table 1, repeat the method described in the above-mentioned embodiment 2 (only the weight of each component changes), and prepare the anti-yellowing nitro white matte finish paint main paint; The diluent was prepared by repeating the components, proportioning and preparation method of the diluent in Example 2.

[0086] The main paint and the diluent were mixed uniformly according to the weight ratio of 1:1.5, and then applied and dried according to the method described in Example 2 to obtain the anti-yellowing nitro white matte finish paint film.

[0087] For routine performance testing, the method refers to ISO11507:1997, and the results (dry film thickness 20-30 μm) are shown in the corresponding data of "Example 3" in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com