Coupling apparatus and technique for fermentation and separation of succinic acid by expanded bed adsorption and in situ extraction

A coupling device and expanded bed technology, which is applied in the field of coupling devices for in-situ extraction, fermentation and separation of succinic acid by expansion bed adsorption, can solve the problems of fixed-bed chromatography column blockage and inability to achieve in-situ separation, and meet the requirements of disinfection, sterilization, Meet the effect of pollution-free operation and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

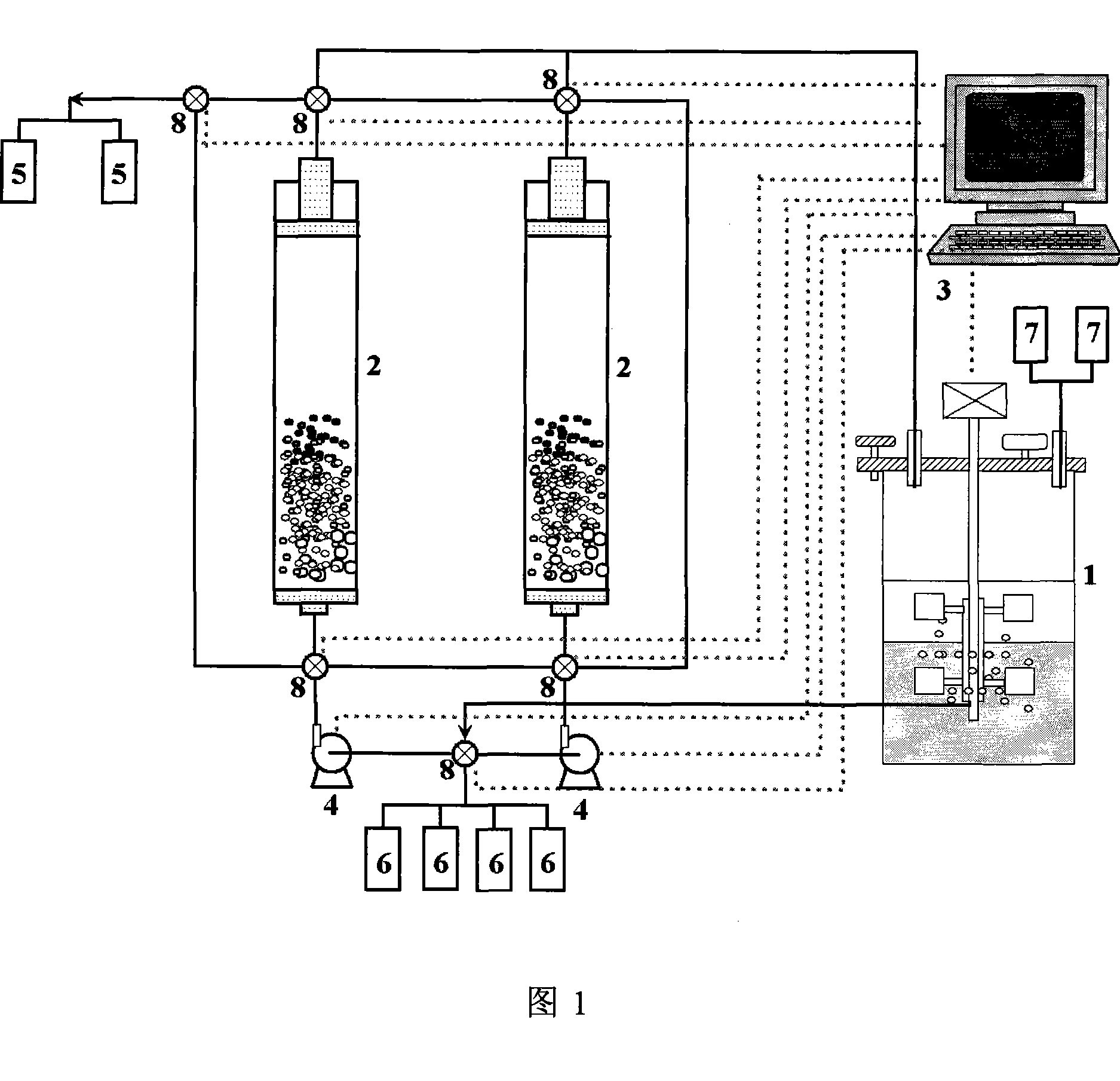

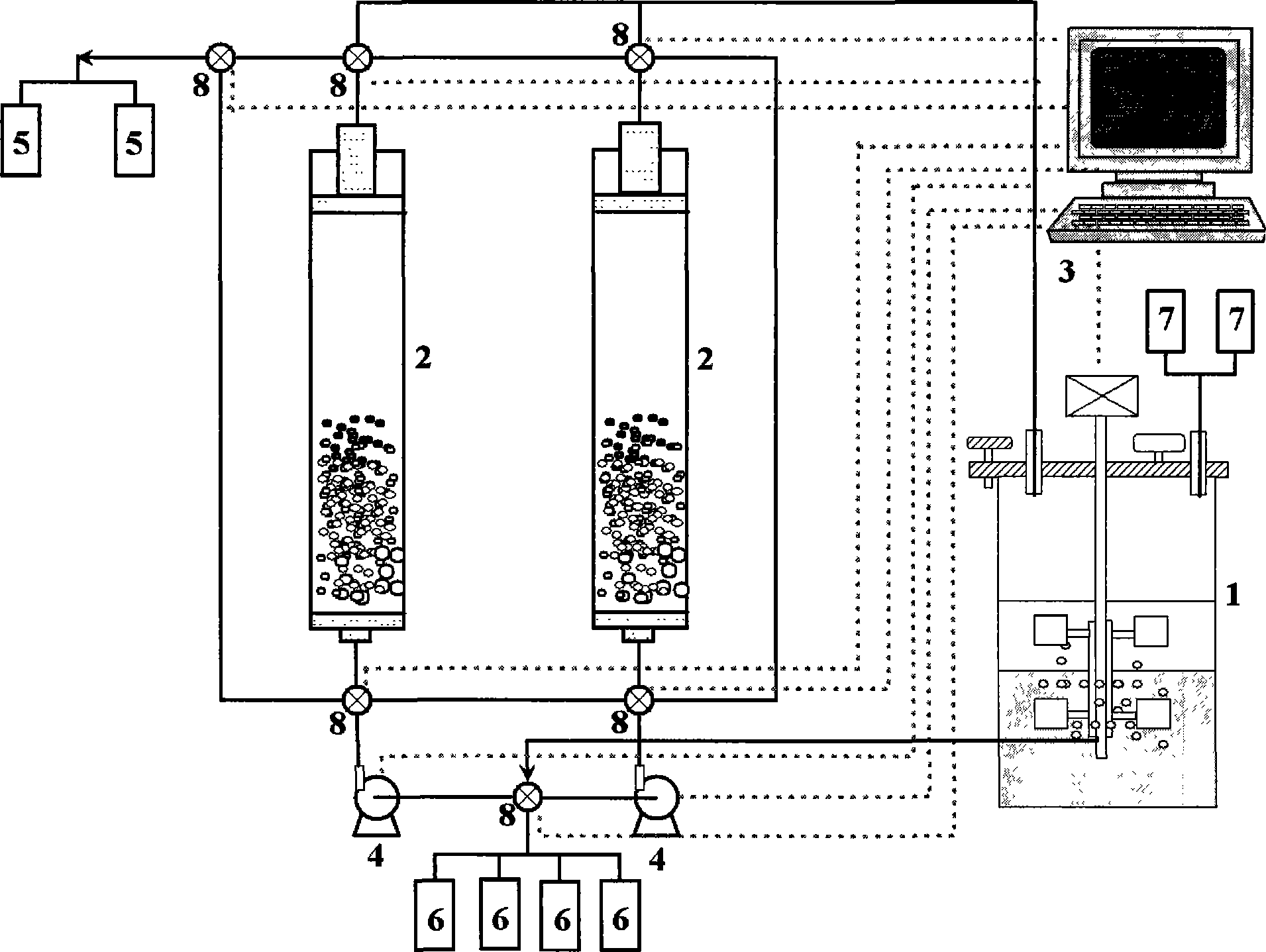

[0034] See Figure 1. Expanded bed adsorption coupling device for in-situ extraction of succinic acid fermentation separation, including 1 bioreactor 1, two parallel expanded bed chromatography columns 2, computer control system 3, two transfer pumps 4, 2 parallel first Liquid storage tank 5, four parallel second liquid storage tanks 6, two parallel high level liquid storage tanks 7, five four-way valves 8 and one three-way valve 8.

[0035] There are circulating fluid inlets at the bottom of the two parallel expanded bed chromatography columns, and circulating fluid outlets at the top of the expanded bed chromatography columns;

[0036] 1. The circulating fluid main pipeline forming the circulating fluid circuit, with one three-way valve and four four-way valves on the main pipeline;

[0037] The four ports of the two four-way valves on the circulating fluid main pipeline at the upper part of the expanded bed chromatography column communicate with the circulating fluid outlet...

Embodiment 2

[0049] The system of Example 1 was used.

[0050] With the fermentation and separation conditions of Example 1, the fermentation results of the first ten cycles of feeding (including supplementing concentrated sugar solution, nitrogen source and inorganic salt ions) are shown in Table 2. The initial sugar is almost consumed within 72 hours and needs to be supplemented with sugar solution. The consumption of other medium nutrients is not listed here, and other nutrients except concentrated sugar solution can be stored in the high-level liquid storage tank connected to the bioreactor as the feed content.

[0051] Table 2 Fermentation results of ten separation cycles without feeding

[0052] Time (cumulative hours)

[0053] 0

Embodiment 3

[0055] The system of Example 1 was used.

[0056] The sources and types of expanded bed chromatography column packing resins are shown in the first to third columns of Table 3. The resin was first soaked in deionized water for 24 hours, and then passed through four times of "4wt% HCl, water, 4wt% NaOH and Water" pretreatment, the resin is treated as -OH type, and finally the bed is washed with sterile water until the pH value of the effluent is neutral, then the fermentation broth can be prepared for sampling; after reaching the saturated adsorption capacity, select 1wt% ~ 3wt% NaOH or 40wt%-80wt% NaCl is used as eluent for elution. Macroporous adsorption resin or polyvinylpyridine adsorption resin uses 90°C hot water or ethanol as a desorbent, and in this case the pH of the fermentation broth is controlled by adding ammonia water or NaOH. See Table 3 for the effect and acid production of the selected resin after one adsorption, elution, and regeneration cycle of the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com