Variable nozzle turbocharging control method and system

A technology of turbocharging and control methods, applied in electrical control, engine control, gas turbine devices, etc., can solve the problem of inability to continuously adjust the position of the nozzle section, difficulty in improving low-speed performance, and inability to provide supercharging pressure and air intake, etc. problem, to achieve the effect of increasing the intake air volume and output torque, increasing the feedback control speed, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

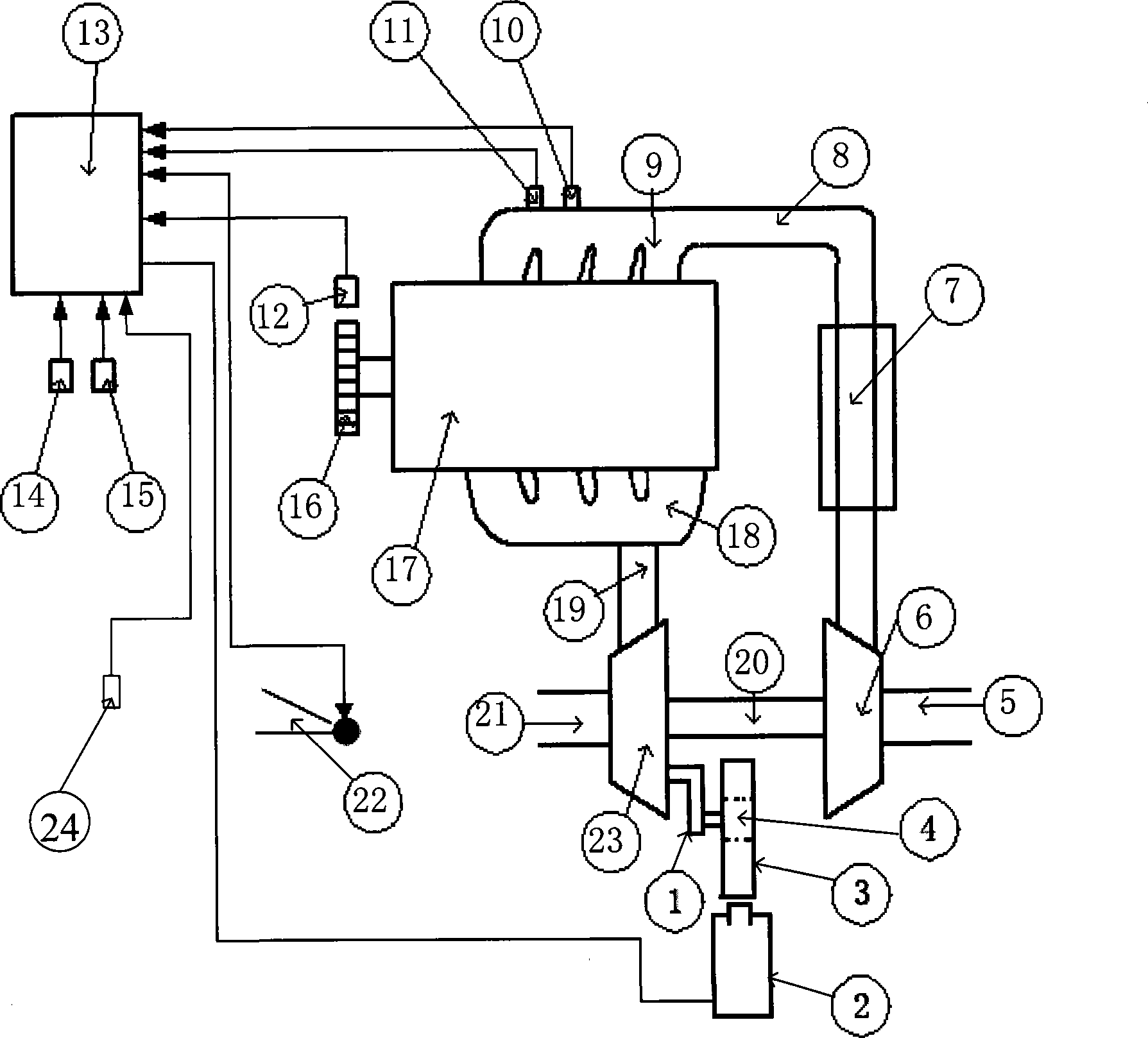

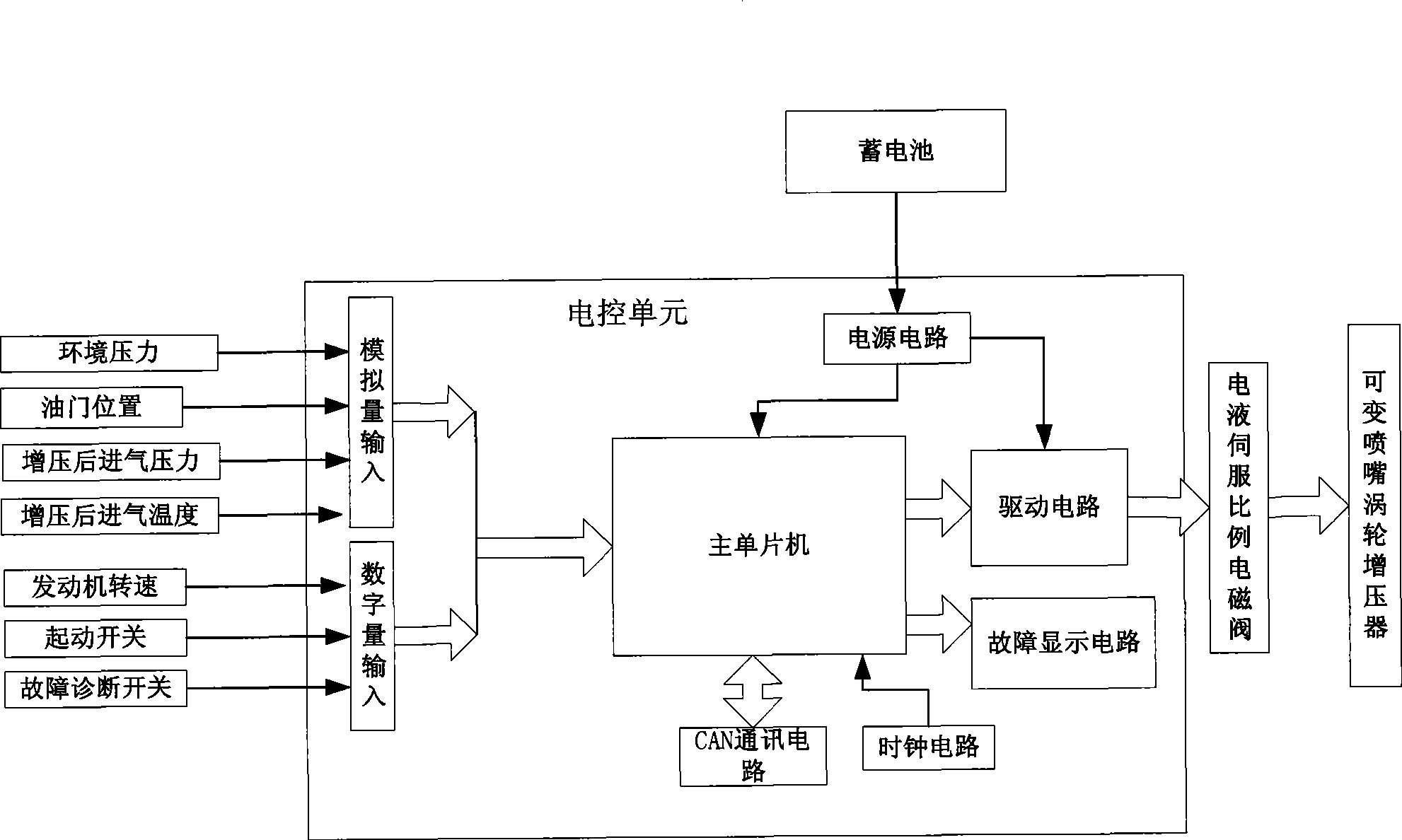

[0042] figure 1 It is a connection diagram of the supercharging system of the present invention. The control system includes a variable nozzle turbocharger, an electronic control unit 13, an electro-hydraulic servo proportional solenoid valve 2 for adjusting the opening of the turbine nozzle ring, an engine speed sensor 12, an accelerator pedal position sensor 22, and a boost pressure sensor 10 , intake air temperature sensor 11, atmospheric environment pressure sensor 24, start switch 14, fault diagnosis switch 15 and the program stored in advance in the single-chip microcomputer of electronic control unit. The engine speed sensor 12 is installed at the engine flywheel 16 for collecting engine speed signals. The engine accelerator position sensor 22 is installed on the accelerator pedal, and when the driver steps on the pedal, the sensor and the pedal rotate coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com