Policosanol drop pill and preparation method thereof

A technology of policosanol and dripping pills, which is applied in the direction of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of difficult biological activity, poor bioavailability, poor solubility, etc., and achieve improved Bioavailability, low production cost, high bioavailability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

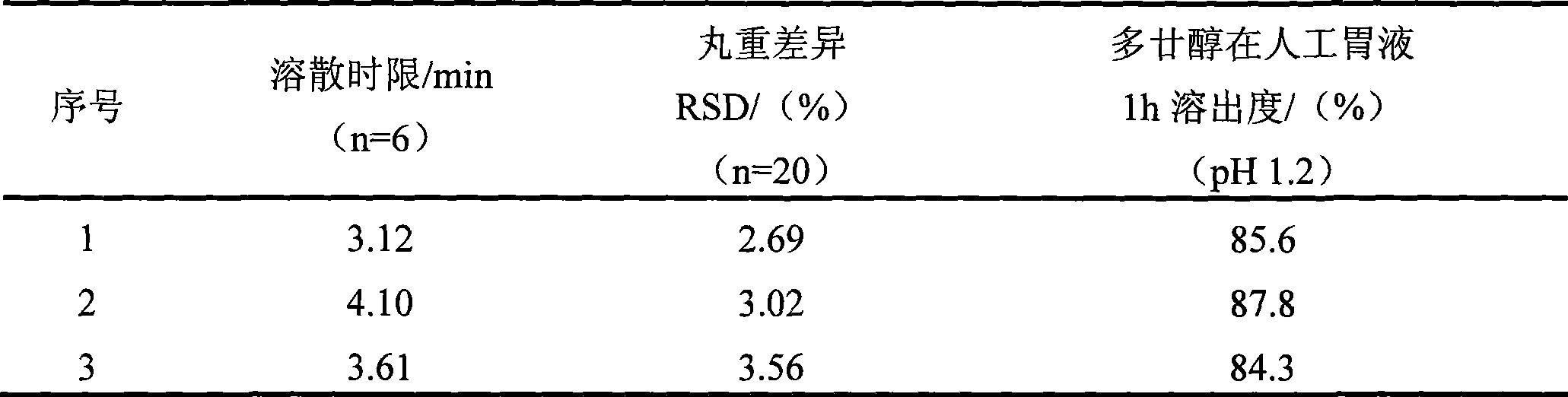

Embodiment 1

[0047] Preparation of policosan drop pills (1)

[0048] Prescription (specification: containing policosanol 2.00mg / pill, pill weight 45mg)

[0049] Polycohol 10.0g

[0050] Macrogol 1500 50.2g

[0051] Polyethylene glycol 6000 150.0g

[0052] Tween 20 14.8g

[0053] A total of 5000 capsules were made.

[0054] Experimental method: take 50.2g of polyethylene glycol 1500, 150.0g of polyethylene glycol 6000, and 14.8g of Tween 20, and then add 10.0g of policosanol raw material powder, stir and mix evenly, and use electric heating to prepare The mixture of raw and auxiliary materials is heated to a molten state, and a special dropping pill machine is used to adjust the dropper temperature and keep it at 85°C (error <2%); using methyl silicone oil as a condensing agent, adjust the refrigeration control system of the dropping pill machine Keep the temperature of the condensing agent at 20 to -5°C (error <5%), then drip according to the method given in the previous preparation p...

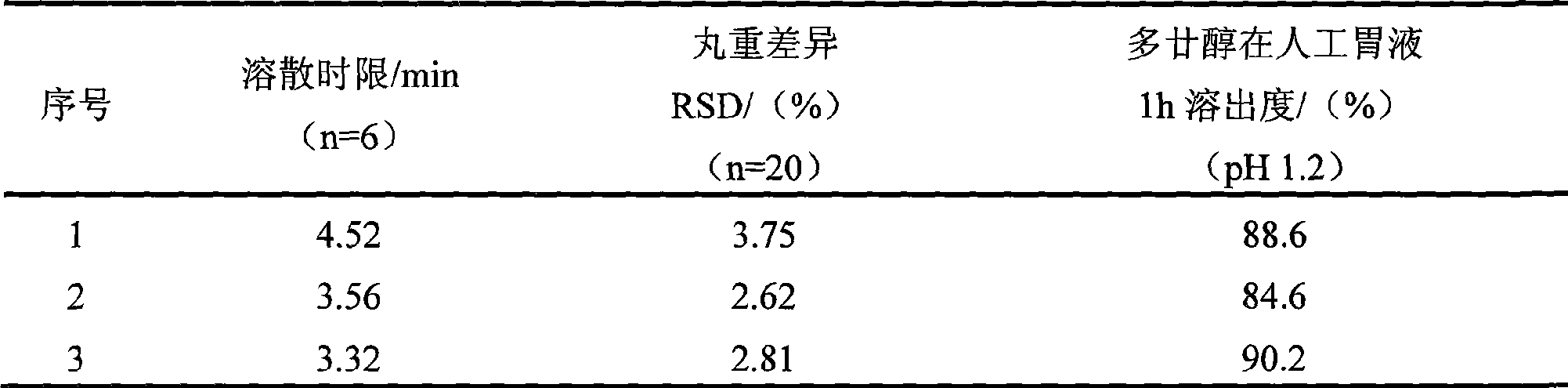

Embodiment 2

[0059] Preparation of policosan dropping pills (2)

[0060] Prescription (specification: containing policosanol 2.0mg / pill, pill weight 40mg)

[0061] Polycohol 10.0g

[0062] Macrogol 2000 79.7g

[0063] Macrogol 4000 100.0g

[0064] Benzaze 58 10.3g

[0065] A total of 5000 capsules were made.

[0066] Experimental method: Take 79.7g of polyethylene glycol 2000, 100.0g of polyethylene glycol 4000, 10.3g of Benze 58, and then add 10.0g of policosanol raw material powder, stir and mix evenly, and use electric heating to prepare The mixture of raw and auxiliary materials is heated to a molten state, and a special dropping pill machine is used to adjust the dropper temperature and keep it at 85°C (error <2%); using methyl silicone oil as a condensing agent, adjust the refrigeration control system of the dropping pill machine Keep the temperature of the condensing agent at 20 to -5°C (error <5%), then drip according to the method given in the previous preparation process, ta...

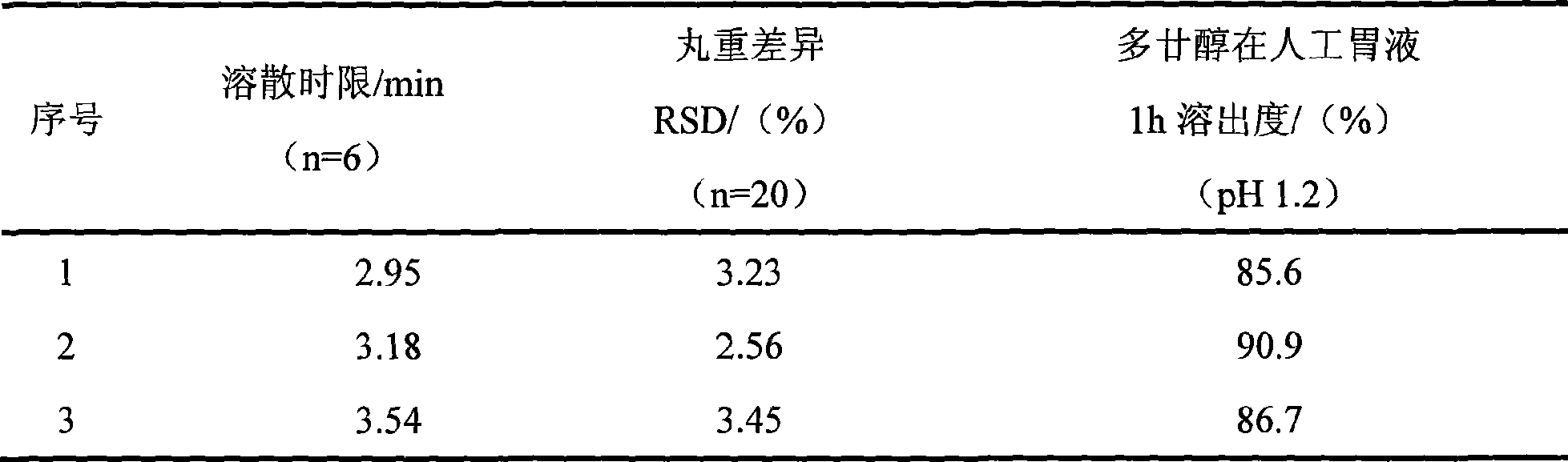

Embodiment 3

[0071] Preparation of policosanol dropping pills (3)

[0072] Prescription (specification: policosanol 1.0mg / pill, pill weight 34.2mg)

[0073] Polycohol 10.0g

[0074] Macrogol 2000 57.6g

[0075] Macrogol 4000 142.4g

[0076] Polyethylene glycol 6000 100.0g

[0077] Benzaze 35 32.4g

[0078] A total of 10,000 capsules were made.

[0079] Method: Take 57.6g of polyethylene glycol 2000, 142.4g of polyethylene glycol 4000, 100.0g of polyethylene glycol 6000, and 32.4g of Benze 35 and mix them evenly, then add 10.0g of policosanol raw material powder, stir and mix evenly , use electric heating to heat the mixture of raw and auxiliary materials to a molten state, use a self-made special pilling machine, adjust the dripper temperature and keep it at 85°C (error <2%); use methyl silicone oil as the condensation Adjust the refrigeration control system of the dropping pill machine to keep the temperature of the condensing agent at 20 to -5°C (error <5%), and then drip according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com