Broad-width extrusion device and technique thereof

An extrusion device and wide-width technology, applied in the field of wide-width extrusion device and extrusion process, can solve the problems of limited pass reduction, low yield, high cost, etc., to reduce the actual extrusion ratio, reduce Power source power, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Now in conjunction with accompanying drawing, the present invention will be further described:

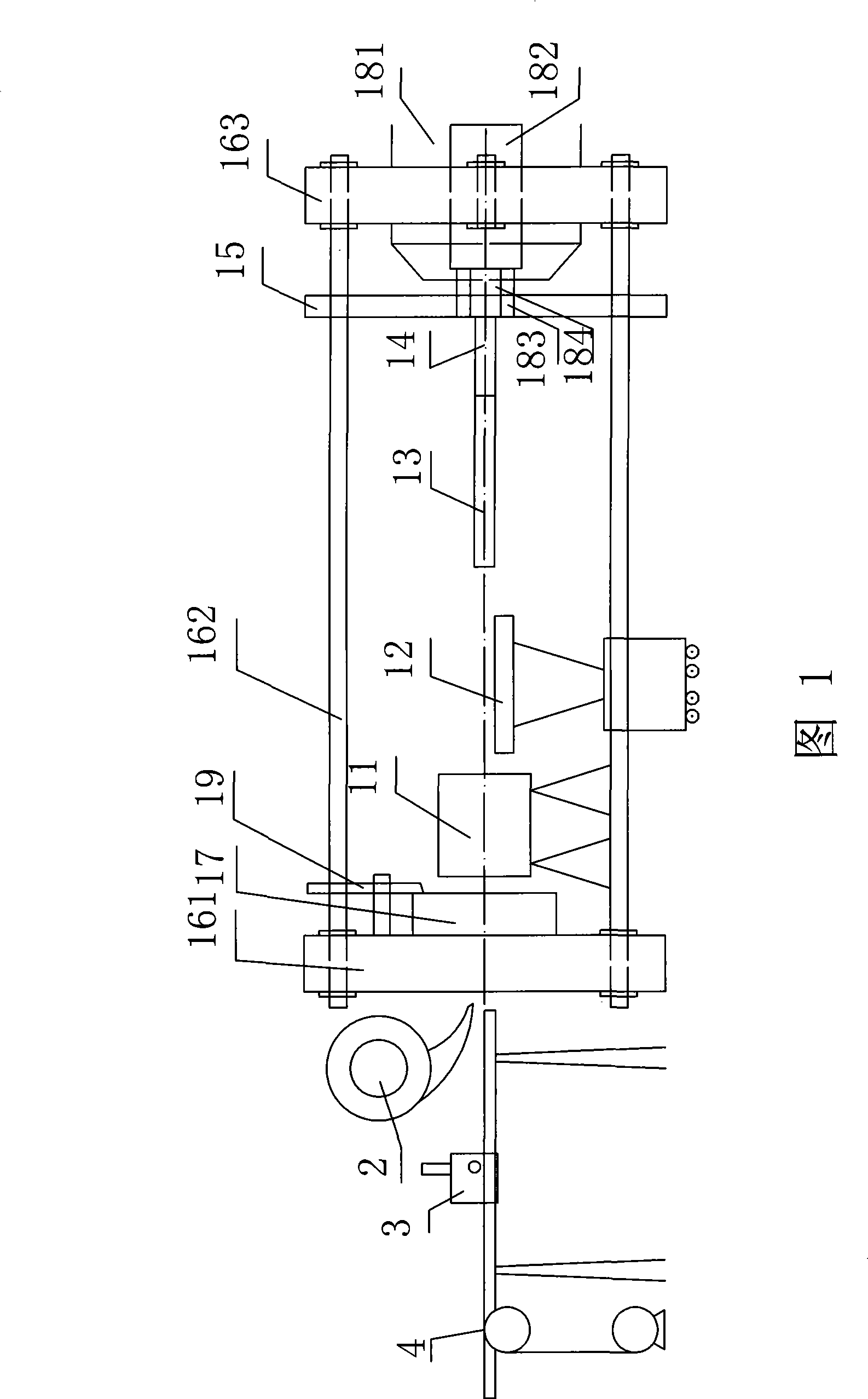

[0059] A wide-width extrusion device includes an extrusion machine and a temperature measurement-cooling system, and is equipped with a cutting machine 3 and a tractor 4, as shown in Figure 1.

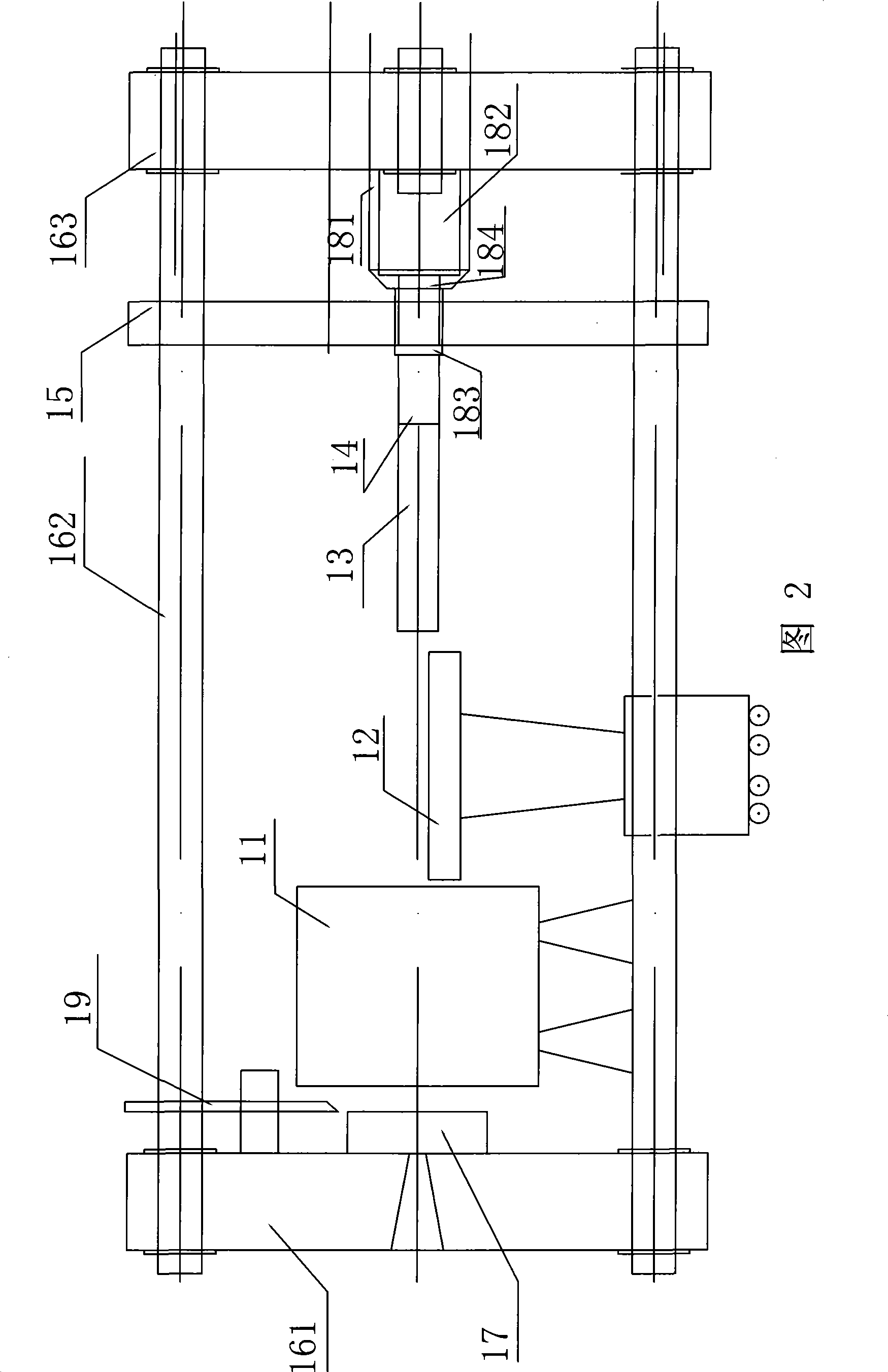

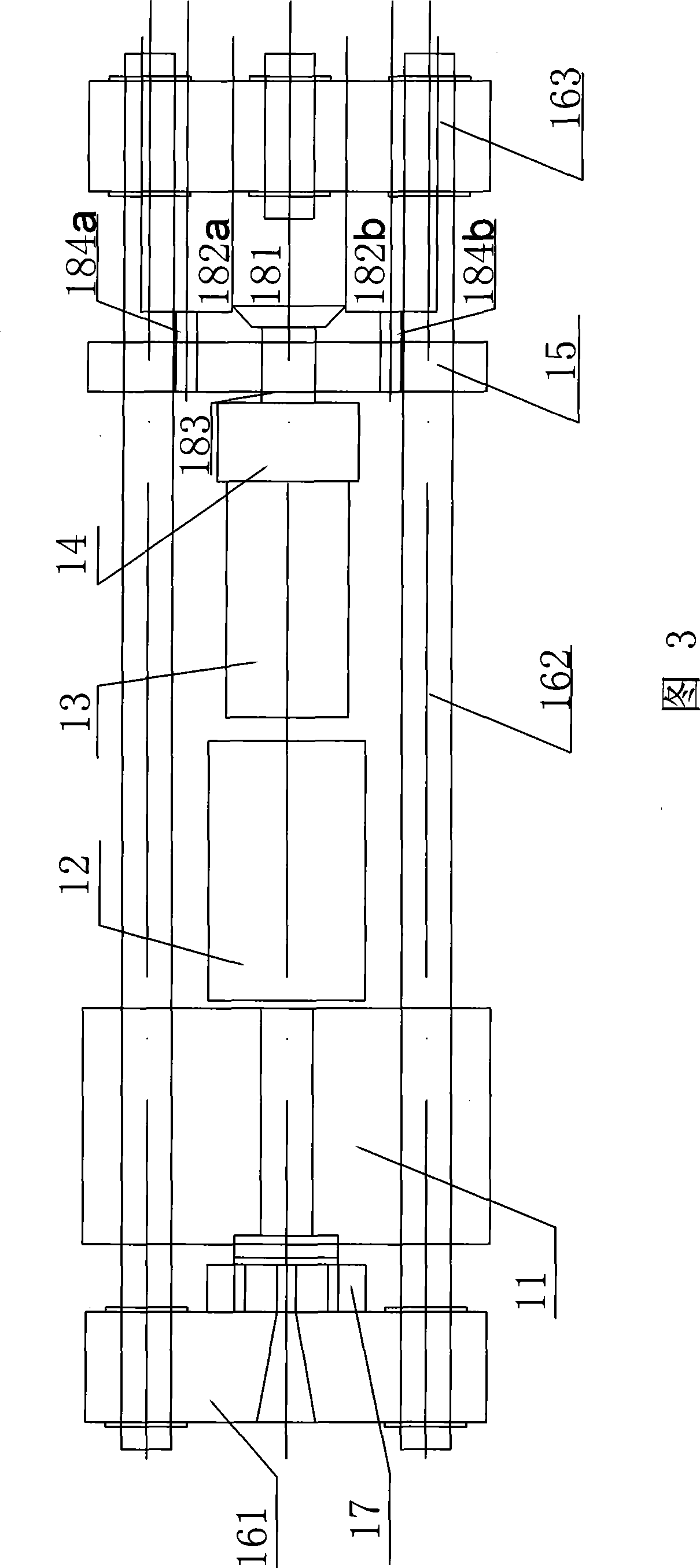

[0060] The extruder, as shown in Figure 1, Figure 2 and Figure 3, includes an extrusion cylinder 11, an extrusion rod-extrusion seat, a main body support-positioning structure, a movable beam 15, a feeding mechanism 12, a combined hydraulic system and control system; among them,

[0061] The extrusion cylinder 11, such as Figure 4 , Figure 5 As shown, there is a rectangular flat extrusion cavity 111 with arc-shaped sides, its height×width=(200~300)×(700~800)mm, and its outer part is a flat extrusion tube jacket 116 adapted thereto; The flat extrusion barrel jacket 116 has an elliptical cross-section, and the extrusion chamber 111 and the jacket 116 include an extrusion barrel li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com