Compositions comprising melt-processable thermoplastic fluoropolymers and methods of making the same

A melt-processing, polymer technology, applied in the field of compositions comprising melt-processable thermoplastic fluoropolymers and their manufacture, capable of solving problems such as melt cone fractures, production interruptions, detachment of die deposits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0097] method

[0098] Melt Flow Index (MFI) was measured according to ASTM D-1238 under a load of 5.0 kg and reported in g / 10 min. Unless otherwise stated, a temperature of 265°C was applied and a standard extrusion die with a diameter of 2.1 mm and a length of 8.0 mm was used.

[0099] The melting peak of the fluororesin was determined according to ASTM 4591 using Perkin-Elmer DSC 7.0 (PerkinElmer, Wellesley, MA) under nitrogen flow and a heating rate of 10°C / min. The indicated melting points refer to the maximum value of the melting peak.

[0100] Latex particle size was determined by dynamic light scattering according to ISO / DIS 13321 with a Malvern Zetazizer 1000 HSA (Malvern Instruments Inc., Southborough, MA). The average particle size reported is the Z-average particle size. Before the measurement, the polymer latex resulting from the polymerization reaction was diluted with a 0.001 mol / L KCl solution, and the measurement temperature was 20° C. in all cases.

[0...

example 1

[0107] A terpolymer having a linear linear structure of 39 mol % TFE, 11 mol % HFP and 50 mol % VDF was prepared in a polymerization tank with a total volume of 48.5 liters equipped with an impeller agitator system according to the following procedure. 29.0 liters of deionized water, 2 g of oxalic acid, 12 g of ammonium oxalate, and 252 g of a 30% by weight aqueous solution of ammonium perfluorooctanoate (APFO) were added to the kettle. Then, the oxygen-free autoclave was heated to a maximum of 40° C. and the stirring system was set at 240 rpm. Add ethane to the kettle to 1.2 bar absolute pressure, add 953g hexafluoropropylene (HFP) to 7.5 bar absolute pressure, add 283g vinylidene fluoride (VDF) to 11.7 bar absolute pressure and add 429g tetrafluoroethylene (TFE) to The reaction pressure was 15.5 bar (absolute pressure). By adding 10ml 1.0% potassium permanganate (KMnO 4 ) aqueous solution initiates the polymerization, and maintains KMnO with a feed rate of 120ml / h 4 Conti...

example 2

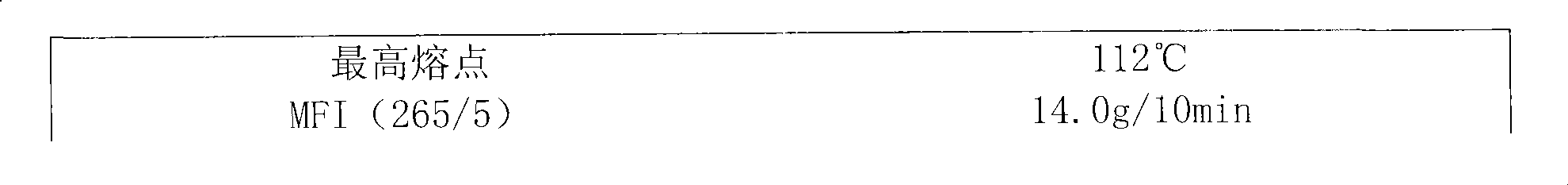

[0112] Utilize the method similar to example 1 to prepare the high molecular weight fluoropolymer with linear straight chain structure, difference only is to press into 0.2bar ethane, and use 0.5% potassium permanganate (KMnO 4 ) aqueous solution. Other polymerization conditions and polymer post-treatment were the same. The resulting polymer has the following physical properties:

[0113]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com