Composite for ultraviolet ray curable cation electrodeposition coating and film thereof

A cationic electrodeposition and curing technology, applied in electrophoretic coatings, coatings, etc., can solve the problems of poor coating stability over time, rising manufacturing costs, complicated reaction procedures, etc., and achieve stable coating performance over time, good The effect of surface curability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

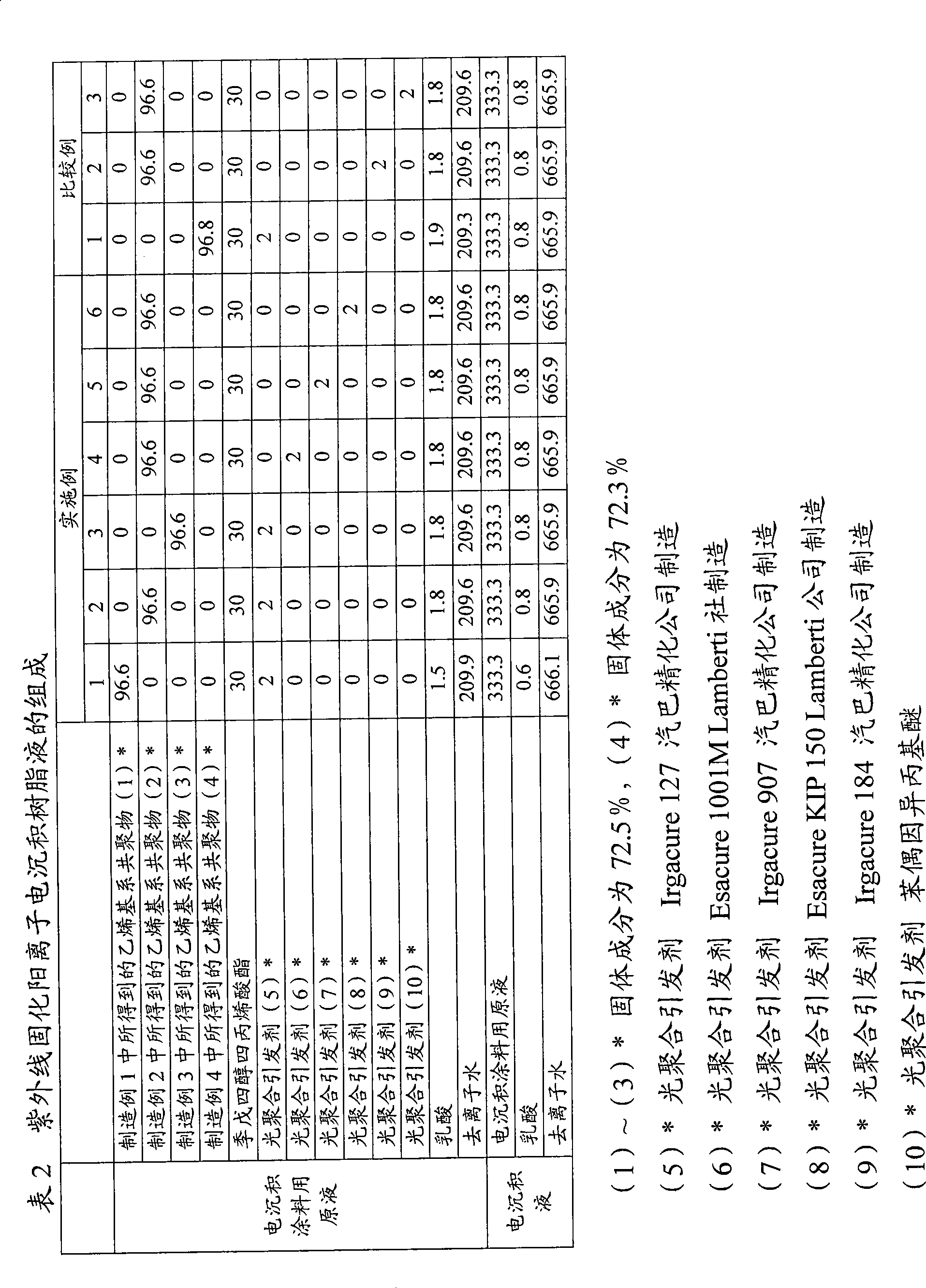

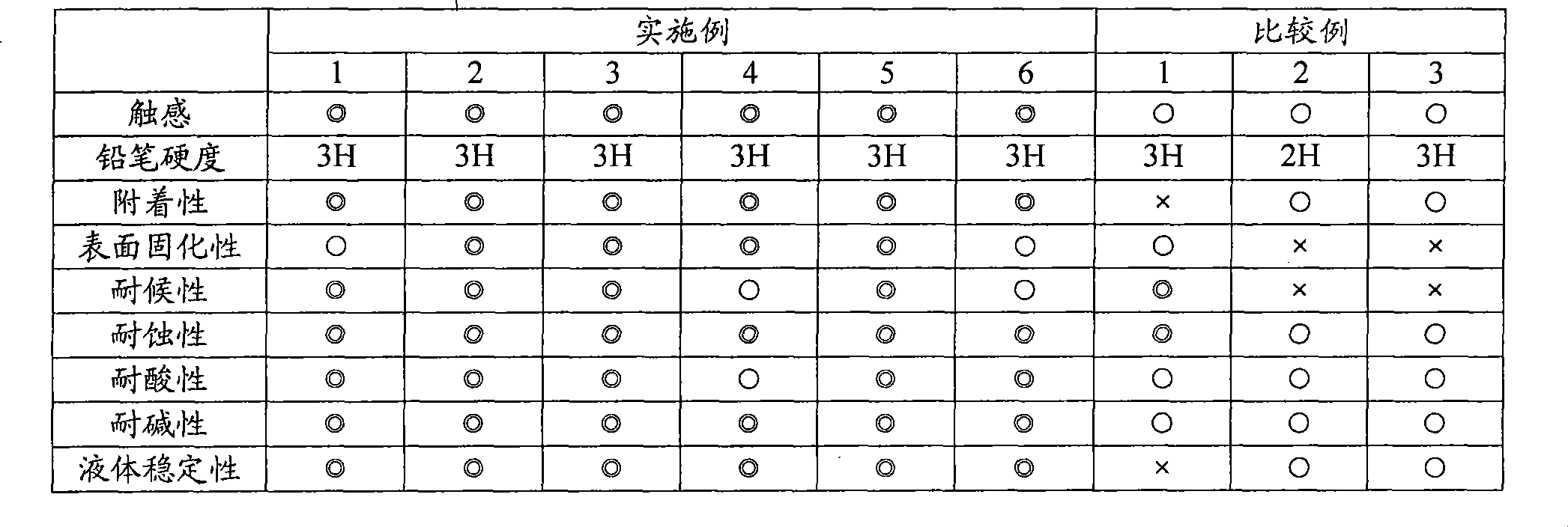

Examples

manufacture example 1

[0069] 10.0 parts of isopropanol and 10.0 parts of propylene glycol monomethyl ether were charged into a 3-liter four-necked flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe, and the temperature was raised to 90°C. In addition, 5 parts of isopropanol, 13 parts of propylene glycol monomethyl ether, 8 parts of diethylaminoethyl methacrylate, 10 parts of 2-hydroxyethyl acrylate, 10 parts of styrene, 20 parts of n-butyl acrylate, The mixed solution of 52 parts of methyl methacrylate, 1.5 parts of azobisisobutyronitrile, and 1 part of 2,4-diphenyl-4-methyl-1-pentene was put into the dropping funnel, and dropped over 120 minutes. into the aforementioned flask. After the dropwise addition was completed, 0.4 parts of propylene glycol monomethyl ether and 0.2 parts of azobisisobutyronitrile were added three times every 30 minutes, and the reaction was continued at 90° C. for 90 minutes. The copolymer thus obtained was a water-dispersible viny...

manufacture example 2

[0071] 10.0 parts of isopropanol and 10.0 parts of propylene glycol monomethyl ether were charged into a 3-liter four-necked flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe, and the temperature was raised to 90°C. In addition, 5 parts of isopropanol, 13 parts of propylene glycol monomethyl ether, 10 parts of diethylaminoethyl methacrylate, 10 parts of 2-hydroxyethyl acrylate, 10 parts of styrene, 20 parts of n-butyl acrylate, The mixed solution of 50 parts of methyl methacrylate, 1.5 parts of azobisisobutyronitrile, and 1 part of 2,4-diphenyl-4-methyl-1-pentene was put into the dropping funnel, and dropped over 120 minutes. into the aforementioned flask. After the dropwise addition, 0.4 parts of propylene glycol monomethyl ether and 0.2 parts of azobisisobutyronitrile were added three times every 30 minutes, and the reaction was continued at 90° C. for 90 minutes. The copolymer thus obtained was a water-dispersible vinyl-based copol...

manufacture example 3

[0073] 10.0 parts of isopropanol and 10.0 parts of propylene glycol monomethyl ether were charged into a 3-liter four-necked flask equipped with a stirring device, a reflux condenser, and a nitrogen introduction pipe, and the temperature was raised to 90°C. In addition, 5 parts of isopropanol, 13 parts of propylene glycol monomethyl ether, 10 parts of diethylaminoethyl methacrylate, 10 parts of 2-hydroxyethyl acrylate, 10 parts of styrene, 10 parts of 2-ethyl acrylate Mixed liquid pack of hexyl ester, 20 parts of n-butyl acrylate, 40 parts of methyl methacrylate, 1.5 parts of azobisisobutyronitrile, and 1 part of 2,4-diphenyl-4-methyl-1-pentene It was put into a dropping funnel and dropped into the aforementioned flask over 120 minutes. After the dropwise addition, 0.4 parts of propylene glycol monomethyl ether and 0.2 parts of azobisisobutyronitrile were added three times every 30 minutes, and the reaction was continued at 90° C. for 90 minutes. The copolymer thus obtained w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com