Polishing liquid and polishing method

A technology of polishing liquid and polishing pad, applied in chemical instruments and methods, grinding/polishing equipment, machine tools for surface polishing, etc., which can solve the problems of low-k film firmness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

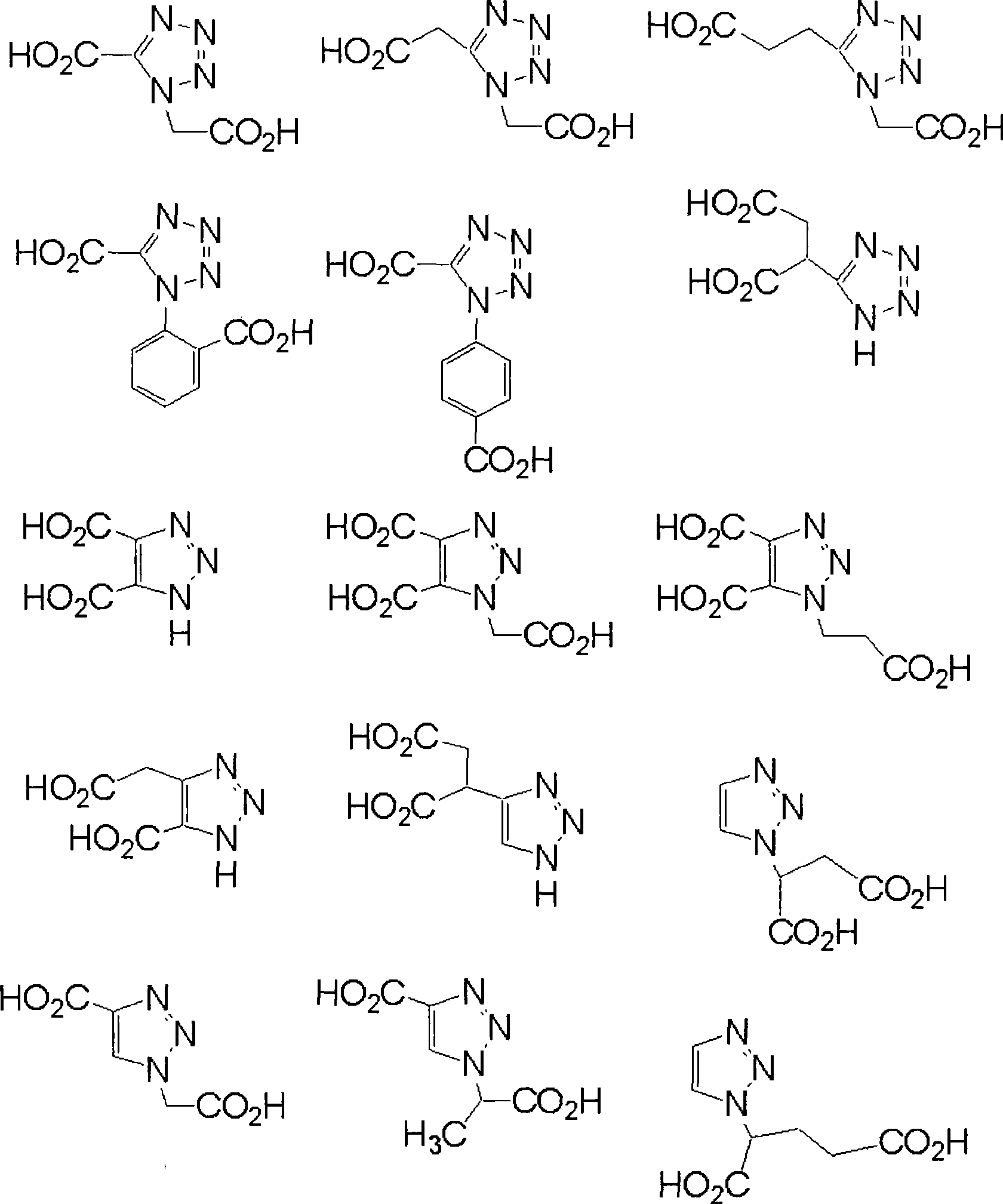

Method used

Image

Examples

Embodiment 1

[0171] A polishing liquid having a composition shown below was prepared, and a polishing test was performed.

[0172] Composition 1:

[0173] (1) Surface modified particles

[0174] Surface modified particles as described below 150g / L

[0175] (2) Organic acid

[0176] Citric acid 1.7g / L

[0177] (3) Specific azole compounds

[0178] 2-(1H-1,2,3-triazol-4-yl)succinic acid 1.3g / L

[0179] (4) Oxidizing agent

[0181] Pure water was added to the composition having the above composition 1 to obtain a total amount of 1,000 ml, and the pH of the solution was adjusted to 6.5 using ammonia water and nitric acid.

[0182] Surface Modified Particles 1

[0183] By reacting 200 g of styrene-methacrylic acid copolymer particles (organic polymer particles) and 10 g of tetraisopropyl bis(dioctyl phosphite) titanate (a compound containing specific inorganic atoms), 100 g of raw silicon Tetraethyl acetate was added thereto to prepare surface-modified pa...

Embodiment 2 to 17 and comparative example 1 to 3

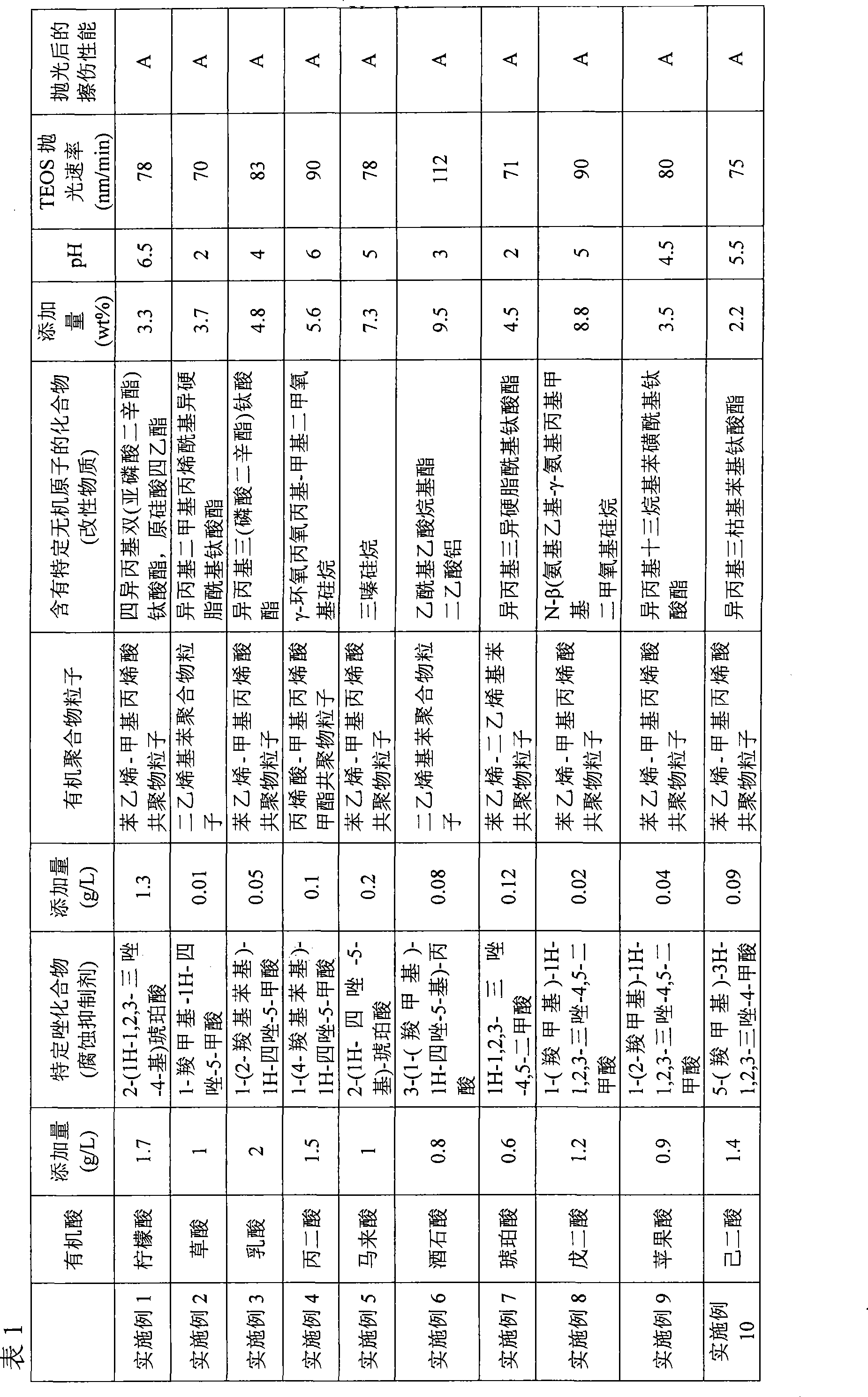

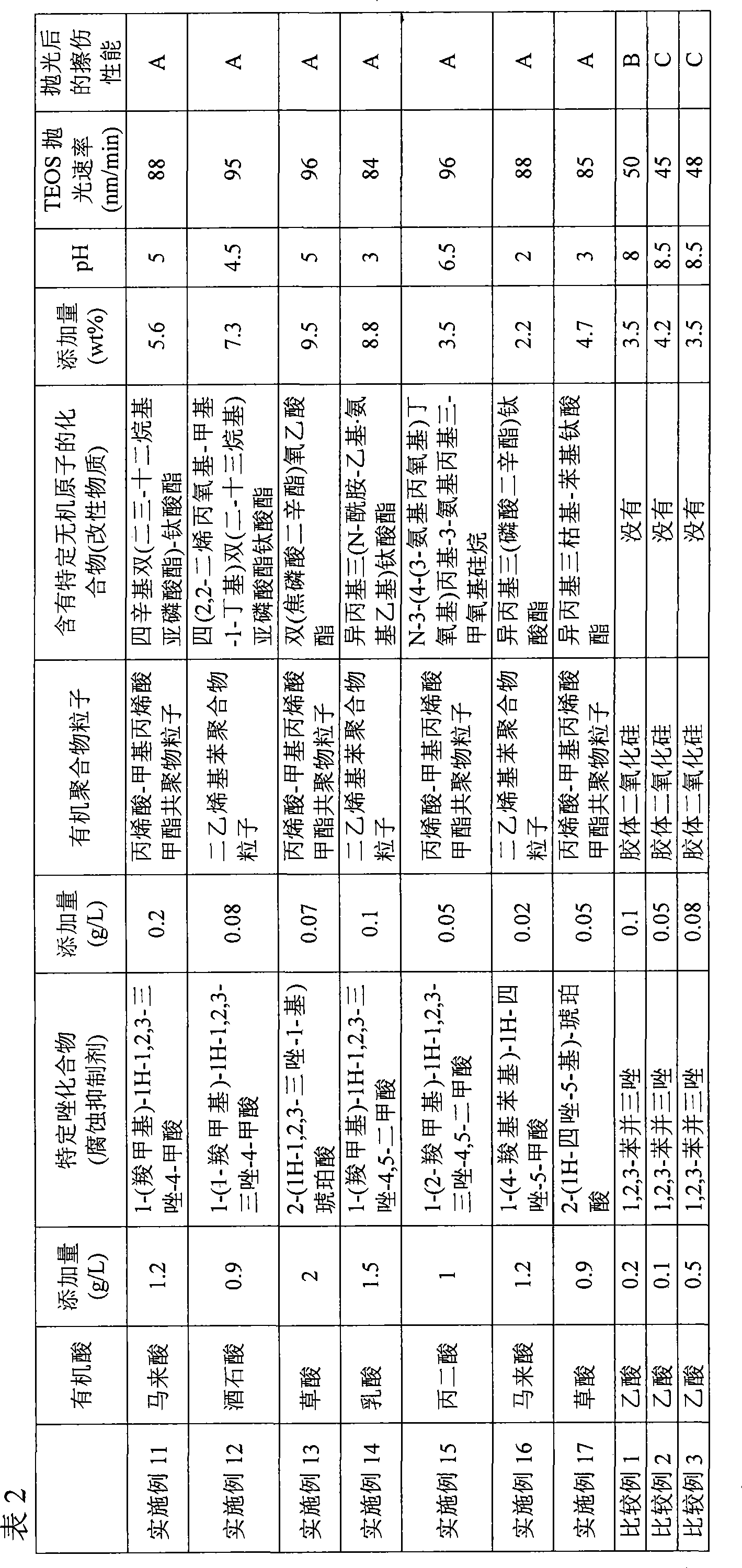

[0207] Each polishing liquid was obtained in the same manner as in the preparation of the polishing liquid of Example 1, except that Composition 1 was changed to Examples 2 to 17 and Comparative Examples 1 to 3 shown in Tables 1 and 2 below Each composition, and the pH values were adjusted as shown in Tables 1 and 2 below. Using each of the obtained polishing liquids, a polishing test was performed under the same conditions as in Example 1. The results obtained are shown in Tables 1 and 2 below.

[0208]

[0209]

[0210] According to Table 1 and Table 2, when the polishing liquids of Examples 1 to 17 were used, compared with Comparative Examples 1 to 3, the polishing rate of TEOS was high, and the scratch property was excellent. On the other hand, the polishing liquids of Comparative Examples 1 to 3 were inferior in each of the TEOS polishing rate and scratch performance, compared with the polishing liquids of Examples.

[0211] From the above, it was found that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com