Flame-retardant shaping phase-change material and preparation method thereof

A technology of shape-setting phase change materials and intumescent flame retardants, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of excellent flame retardancy, good shape setting performance, and high thermal conductivity, and achieve excellent thermal conductivity, Effect of improving thermal conductivity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Raise the temperature of the open rubber mixing machine to 180°C, and roll and melt the high-density polyethylene accounting for 19% of the total system mass percentage, and then mix uniformly the paraffin wax accounting for 60% of the total system mass percentage, 10% ammonium polyphosphate , 5% of pentaerythritol, 5% of melamine and 1% of iron powder are gradually added to the high-density polyethylene, after the addition is completed, melt and blend for 10 minutes, take out the mixture, cool it and add it to a plastic pulverizer for crushing , and then adding the pulverized blend into a screw extruder to melt and extrude it, then granulate and shape it to obtain the flame-retardant fixed phase change material of the present invention.

[0014] The flame-retardant shaped phase-change material press plate prepared in this example was cut into a standard template of 100mm × 100mm × 3mm, and the combustion performance of the material was tested with a cone calorimeter, an...

Embodiment 2

[0020] Open type rubber mixing machine is heated up to 185 ℃, after the high-density polyethylene that accounts for 19% of total system mass percentage is fully rolled and melted, the paraffin wax that accounts for 58% of total system mass percentage, 10% ammonium polyphosphate, 5% of pentaerythritol, 5% of melamine and 3% of iron powder are gradually added to the high-density polyethylene, and after adding, melt and blend for 10 minutes, take out the mixture, add it to a plastic pulverizer after cooling, and pulverize it. Then, the pulverized blend is put into a screw extruder to be melted and extruded, and then granulated and shaped to obtain the flame-retardant fixed phase change material of the present invention.

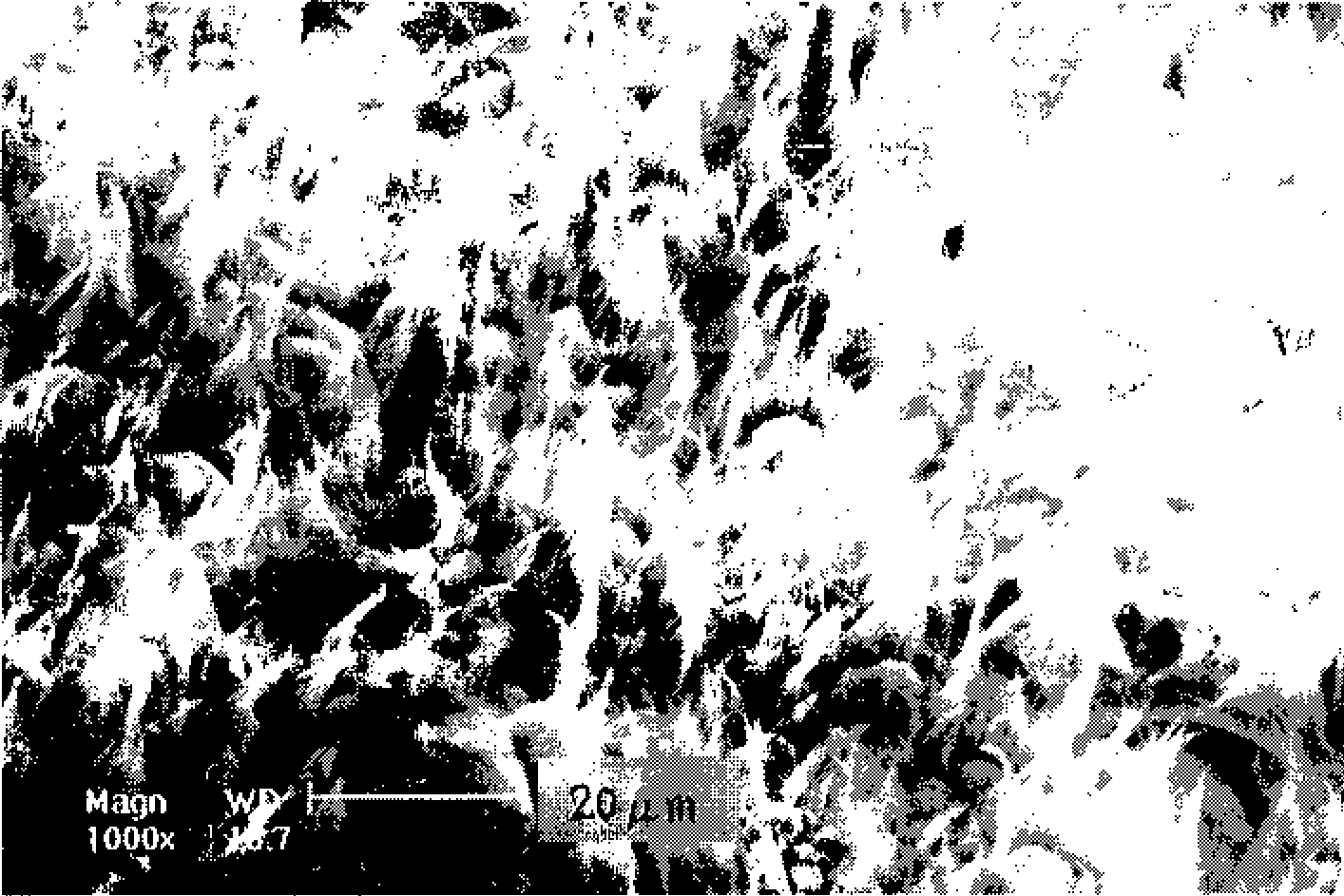

[0021] figure 1 It is a scanning electron microscope photograph enlarged 1000 times for the microstructure of the cross section of the product. From the scanning electron microscope photograph, it can be seen that in the microstructure of the flame retardant fix...

Embodiment 3

[0031] Open type rubber mixing machine is heated up to 185 ℃, after the high-density polyethylene that accounts for 19% of total system mass percentage is fully rolled and melted, the paraffin wax that accounts for 58% of total system mass percentage, 10% ammonium polyphosphate, 5% of pentaerythritol, 5% of melamine and 3% of zinc powder are gradually added to the high-density polyethylene, and after adding, melt and blend for 10 minutes, take out the mixture, add it to a plastic pulverizer after cooling, and pulverize it. Then, the pulverized blend is put into a screw extruder to be melted and extruded, and then granulated and shaped to obtain the flame-retardant fixed phase change material of the present invention.

[0032] The flame-retardant shaped phase-change material press plate prepared above in this embodiment was cut into a standard template of 100mm * 100mm * 3mm, and the combustion performance of the material was tested with a cone calorimeter, and the total heat re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com