Environment-friendly type refrigerating machine oil composition

A technology for refrigerating machine oil and composition, applied in the directions of lubricating composition, petroleum industry, base material, etc., can solve the problem of not using Fischer-Tropsch synthetic wax lubricating oil, etc., and achieve good thermal oxidation stability, good mutual solubility, and low flocculation. point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

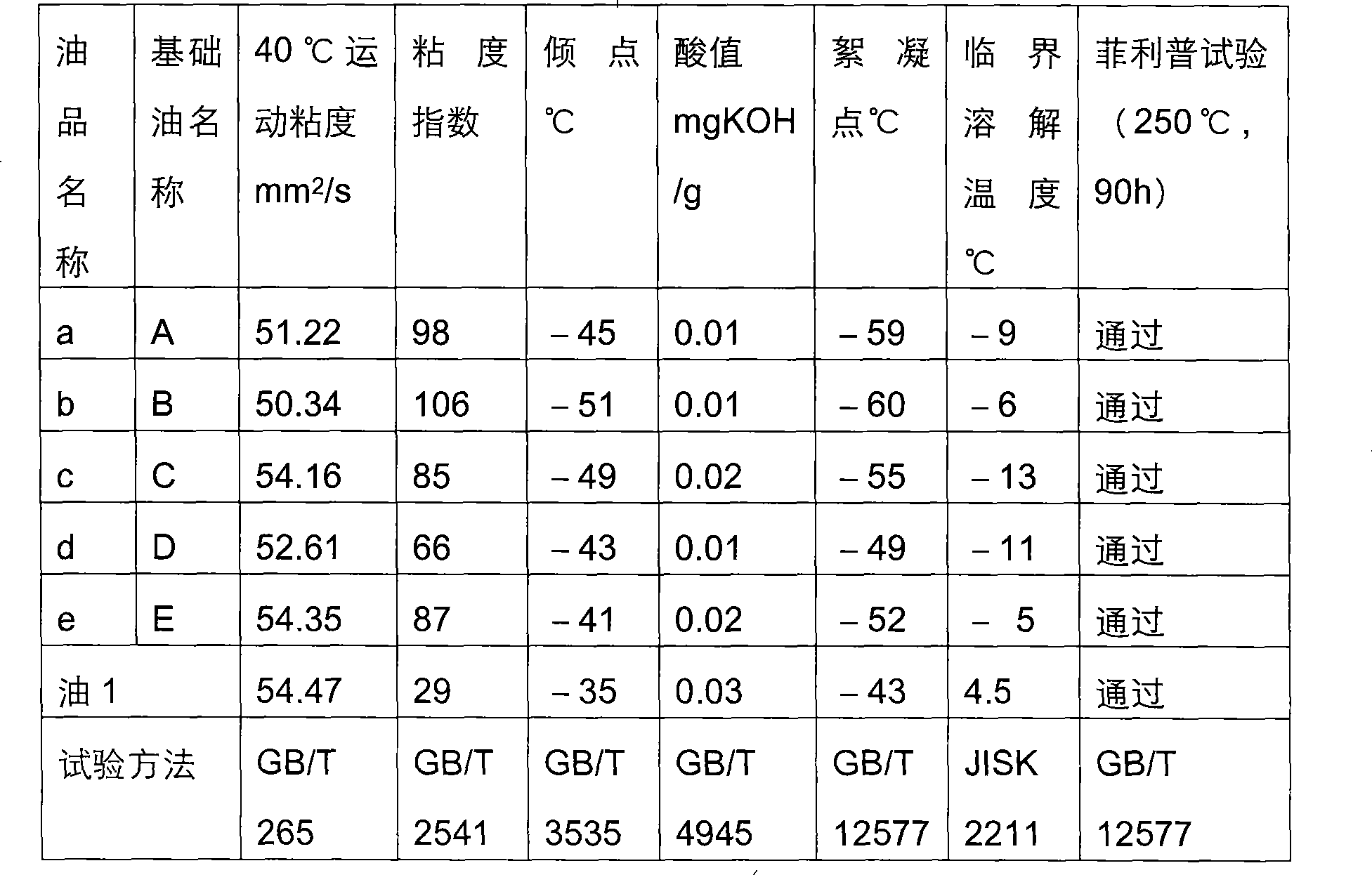

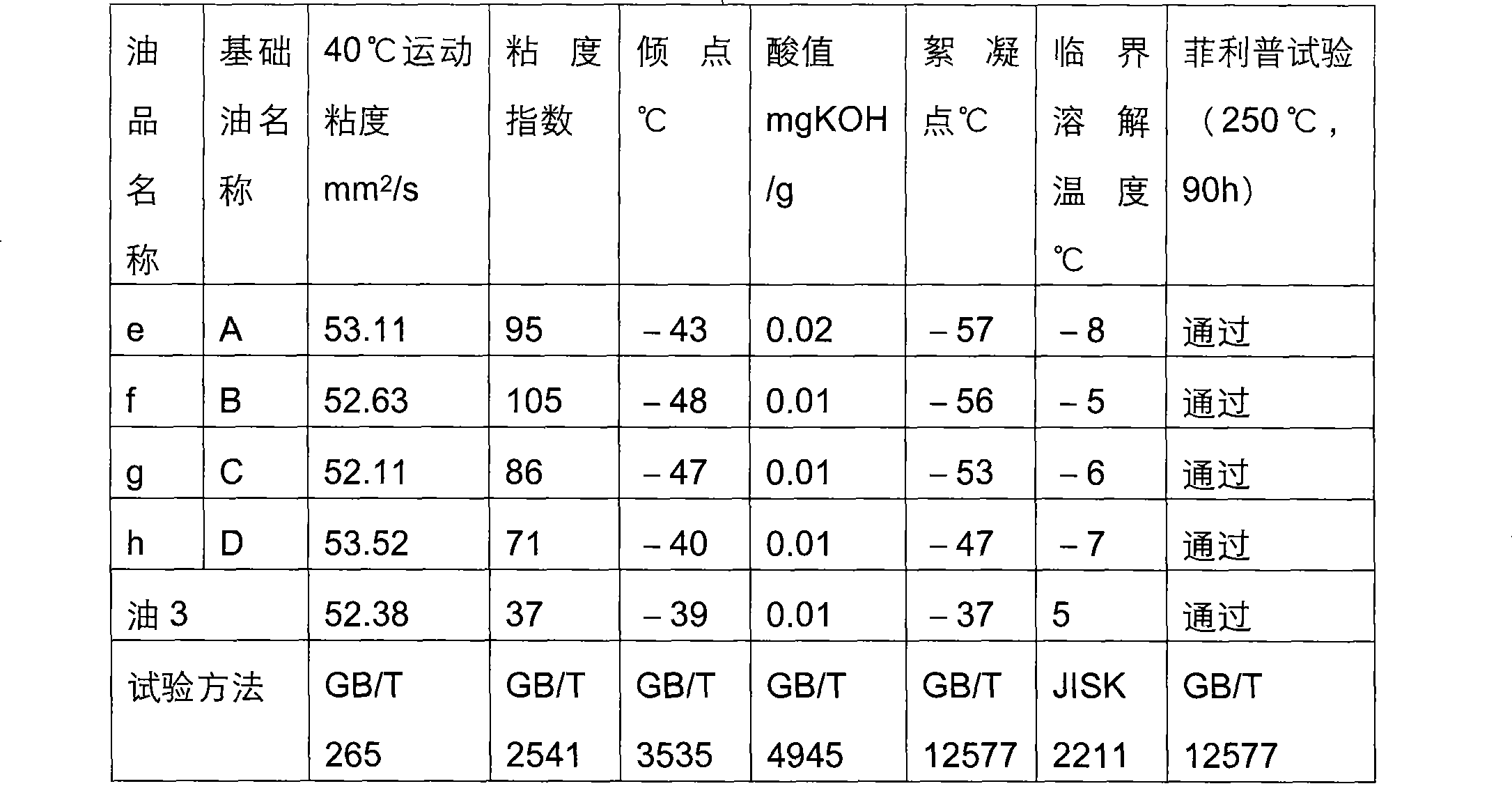

example 1

[0029] Waxes are synthesized from syngas by Fischer-Tropsch reaction over cobalt-thorium catalysts, and the distribution of wax products is as follows:

[0030] <200°C Fraction Mass Percent %: 22

[0031] 200-320 ° C fraction mass percent %: 24

[0032] 320-460 ° C fraction mass percent %: 21

[0033] >460°C Fraction Mass Percent %: 33

[0034] Distill the fraction above 320°C to obtain the following product properties: melting point >100°C, oil content 0, sulfur content 0, nitrogen content 0, oxygen content <0.34, metal content: traces. Normal paraffin content: 90%, isoparaffin content 10%, aromatic content 0.

[0035] The above fractions were subjected to isomerization reaction in a platinum-fluorine modified alumina catalyst fixed bed reactor, the specific conditions were as follows: isomerization temperature 350°C, hydrogen partial pressure 6.8MPa, liquid hourly space velocity 1.0H -1 . Lubricating oil is obtained after the isomerization reaction, and the product dist...

example 2

[0041] Mix fraction 3 and fraction 4 of Example 1 according to the weight ratio of 30:70, the total weight accounts for 80% of the base oil, and then add 4% 2 / s, freezing point -34 DEG C of alkylbenzene and 16% mineral oil (from China Petroleum Karamay Lubricating Oil Factory, naphthene content (CP%) > 40wt%, adjusted to 40 DEG C kinematic viscosity 51.22mm 2 / s refrigerating machine oil base oil A.

example 3

[0043] Mix the above fraction 3 and fraction 4 according to the weight ratio of 28:72, the total weight accounts for 82% of the base oil, and then add 6% 2 / s, freezing point -31°C alkylbenzene and 14% polyalphaolefin synthetic oil second-line oil (from PetroChina Lanzhou Lubricating Oil Factory), adjusted to 40°C kinematic viscosity 50.34mm 2 / s base oil B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com