Environment friendly method for producing diosgenin

A technology of diosgenin and diosgenin, which is applied in the field of diosgenin production by the environmental protection method, can solve the problems of unqualified melting point of saponin, low yield, environmental pollution, etc., achieve low impurity content, short production cycle, and low equipment requirements. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

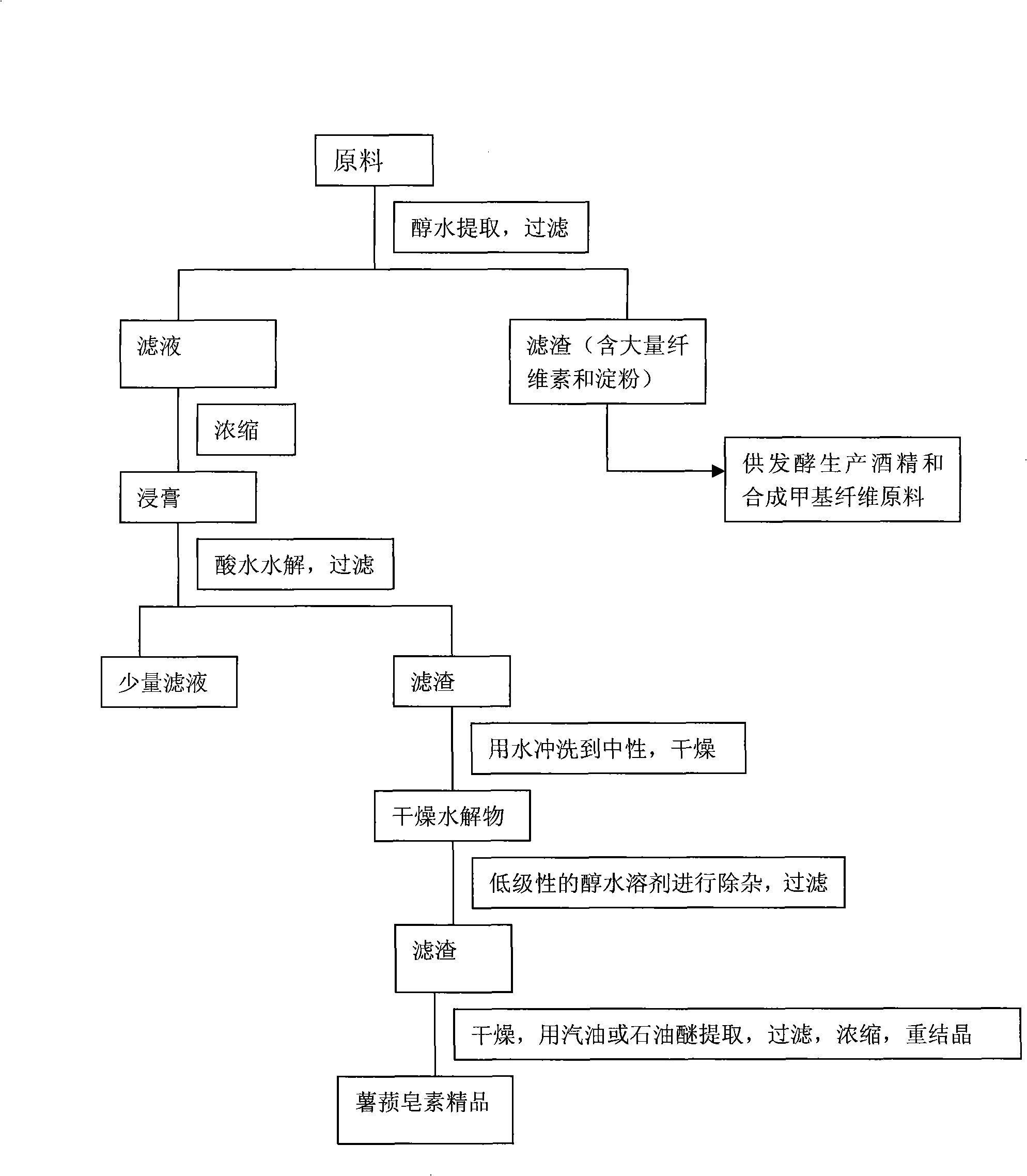

Method used

Image

Examples

Embodiment 1

[0024] Get turmeric dry raw material 1Kg (containing about 2% diosgenin), pulverize, cross 60 mesh sieves, extract three times with 5 times, 5 times, 4 times of volume (based on the quality of raw materials) 80% industrial methanol respectively, extraction time 3h, 2h, 2h respectively. Filtration, the filter residue is used for fermentation to produce alcohol raw materials and synthetic methyl cellulose raw materials, and the combined filtrate is concentrated into an extract. Put the extract into a pressurized hydrolysis tank, add 750ml of 1.25mol / L dilute sulfuric acid, and hydrolyze for 4 hours at 130°C under a pressure of 0.4Mpa. Filter, wash the filter residue with water until neutral, and dry to obtain 50 g of dry hydrolyzate, containing about 40-50% diosgenin. The dried hydrolyzate was extracted twice with 70% methanol to remove impurities, filtered, the filtrate was discarded, and dried to obtain a filter residue. Soxhlet extraction with 120# gasoline for 4 hours, the...

Embodiment 2

[0026] Get fresh turmeric raw material 1Kg (moisture content is about 70%), pulverize, extract three times with 4 times, 3 times, 3 times volume (based on the quality of raw material) 95% industrial methanol respectively, extraction time is respectively 3h, 2h, 2h. Filtration, the filter residue is used for fermentation to produce alcohol raw materials and synthetic methyl cellulose raw materials, and the combined filtrate is concentrated into an extract. Put the extract into an atmospheric pressure hydrolysis tank, add 300ml of 5mol / L dilute hydrochloric acid, and hydrolyze for 8 hours at 100°C. Filter, wash the filter residue with water until neutral, and dry to obtain 14 g of dry hydrolyzate, containing about 40-45% diosgenin. The dried hydrolyzate was extracted twice with 70% methanol to remove impurities, filtered, the filtrate was discarded, and dried to obtain a filter residue. Reflux extraction with 120# gasoline for 3 times, the extracts were combined and concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com