Resin composite material and method of producing the same

A resin composite material and resin technology, applied in the intercalation compound of four resins and its preparation, in the field of nano-organic bentonite and rubber, to achieve the effects of simple production process, excellent mechanical properties, increased compatibility and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

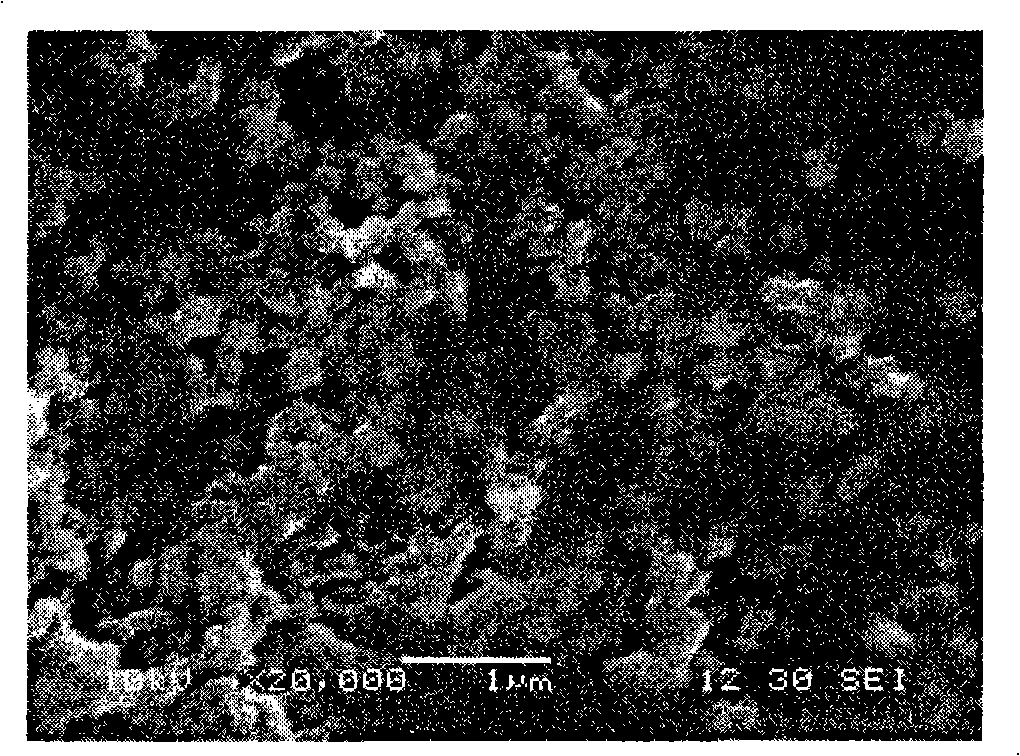

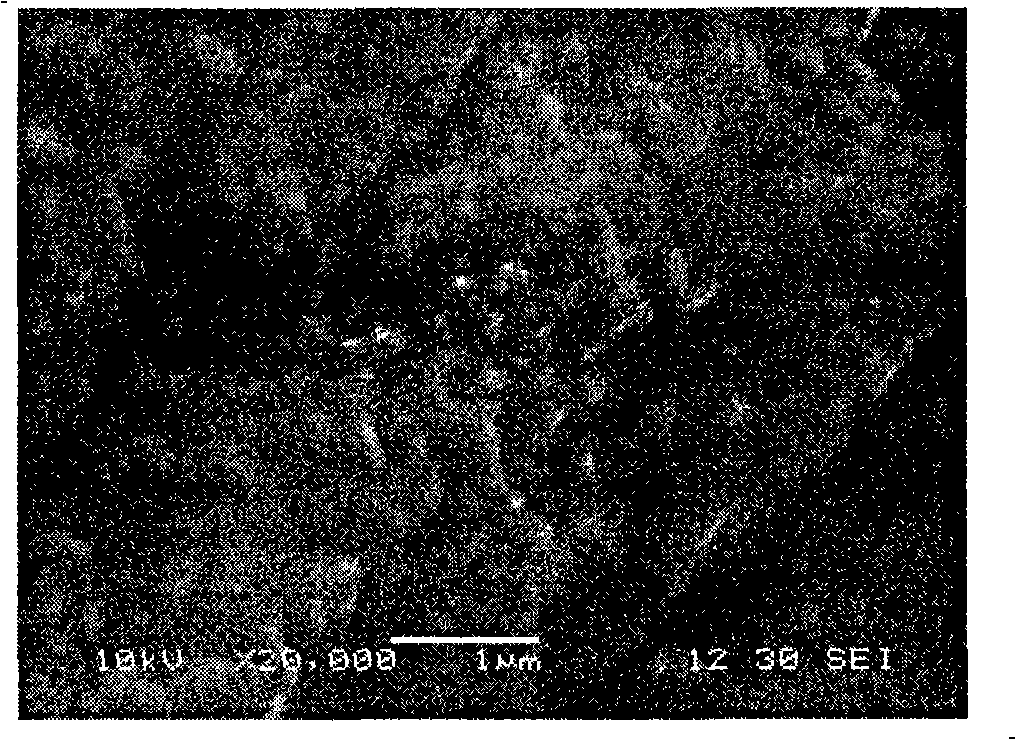

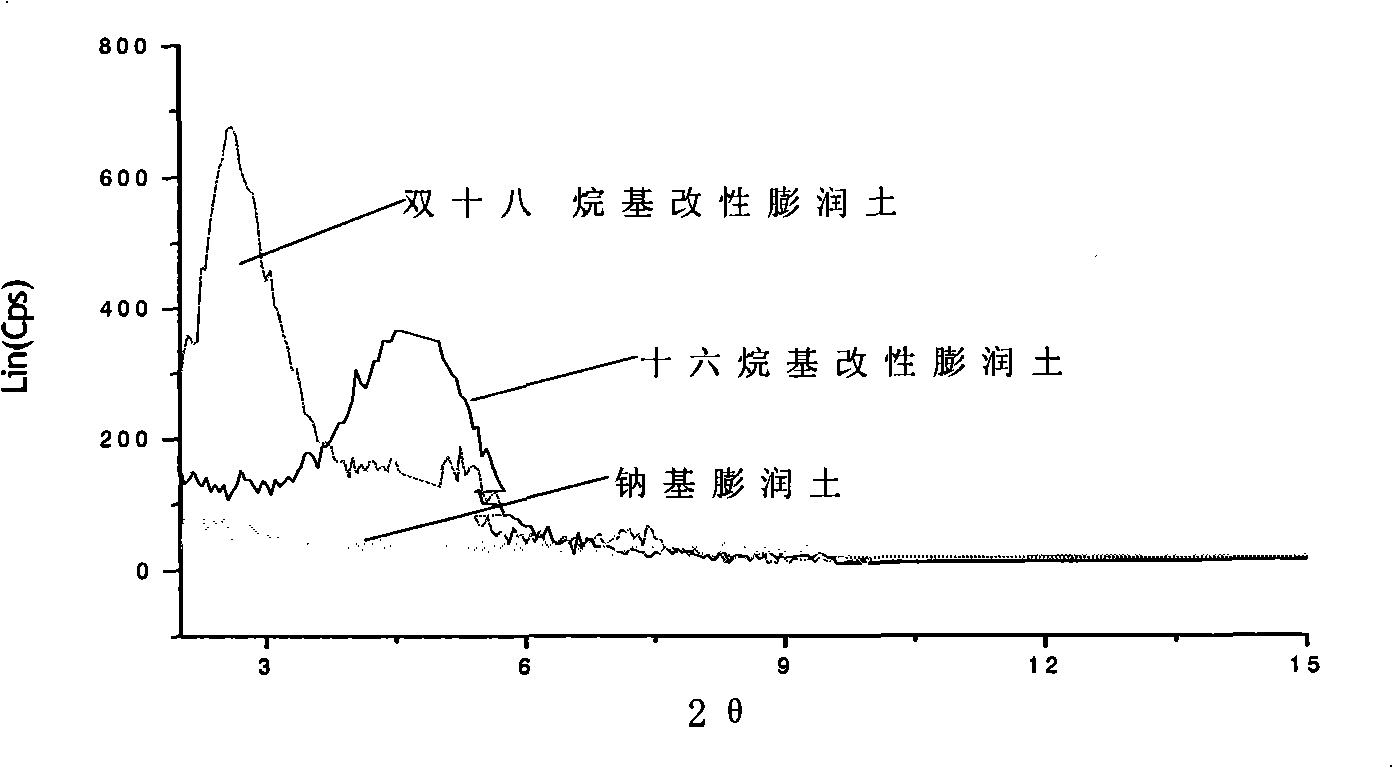

[0046] The preparation method of organic bentonite described in the present invention is as follows:

[0047] (1) Add 10g of sodium bentonite and 500ml of distilled water into a beaker, stir for 30 minutes, and let stand at room temperature for 24 hours to remove a small amount of impurities at the bottom of the bottle;

[0048] (2) In a constant temperature water bath at 70°C, stir for 3 minutes, and add 2ml of sulfuric acid solution with a mass fraction of 2%;

[0049] (3) 8.2g of cetyltrimethylammonium chloride is dissolved in 8.2ml of isopropanol or 11.1g of dioctadecyldimethylammonium chloride is dissolved in 11.1ml of isopropanol, and then Add the resulting solution dropwise to the beaker, and continue to stir for 1h / stirring for 1.5h;

[0050] (4) After standing for stratification, take the flocculent solids, filter them with distilled water and wash them several times until there is no Cl - (0.1mollL AgNO 3 (no white precipitate in the solution test), vacuum-dried t...

Embodiment 1

[0076] The resin is selected from linear low-density polyethylene, and according to the composition and ratio of the above-mentioned resin composite material and the preparation process of the resin composite material, the linear low-density polyethylene resin composite material and the corresponding maleic anhydride grafted linear low-density polyethylene resin are prepared. composite materials;

[0077] The mechanical properties of the obtained LLDPE resin composite are shown in the table below:

[0078]

[0079] The mechanical properties of gained maleic anhydride grafted linear low density polyethylene resin composite material are shown in the following table:

[0080]

[0081] Wherein the preparation method of above-mentioned maleic anhydride grafted linear low-density polyethylene is as follows:

[0082] (1) Weigh 8g of maleic anhydride and 1g of DCP, dissolve it in 20g of acetone, then pour the solution into 1000g of linear low-density polyethylene, mix well, and...

Embodiment 2

[0085] The resin is selected from high-density polyethylene, and according to the composition and ratio of the above-mentioned resin composite material and the preparation process of the resin composite material, a high-density polyethylene resin composite material and a corresponding maleic anhydride grafted high-density polyethylene resin composite material are prepared;

[0086] The mechanical properties of the gained high-density polyethylene resin composite are shown in the table below:

[0087]

[0088] The mechanical property of gained maleic anhydride grafted high-density polyethylene resin composite material is shown in the following table:

[0089]

[0090] Wherein the preparation method of above-mentioned maleic anhydride grafted high-density polyethylene is as follows:

[0091] (1) Weigh 16g of maleic anhydride and 0.7g of DCP, dissolve it in 20g of acetone, then pour the solution into 1000g of high-density polyethylene, mix well, and put it in a fume hood fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com