Green composite additive agent for sauced beef

A compound additive, a technology for sauced beef, applied in application, food preparation, food science, etc., can solve the problems of high cost, immaturity, unsuitable for industrial production, etc., achieve good color development, wide application, good The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

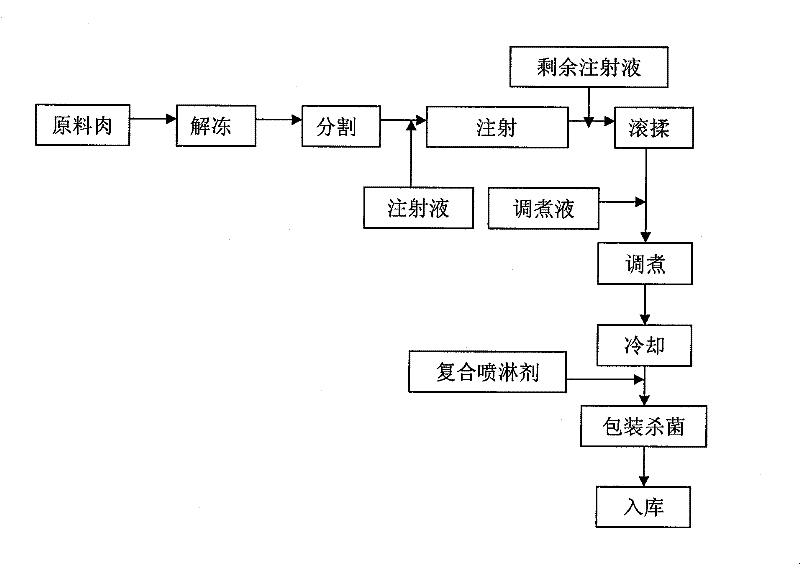

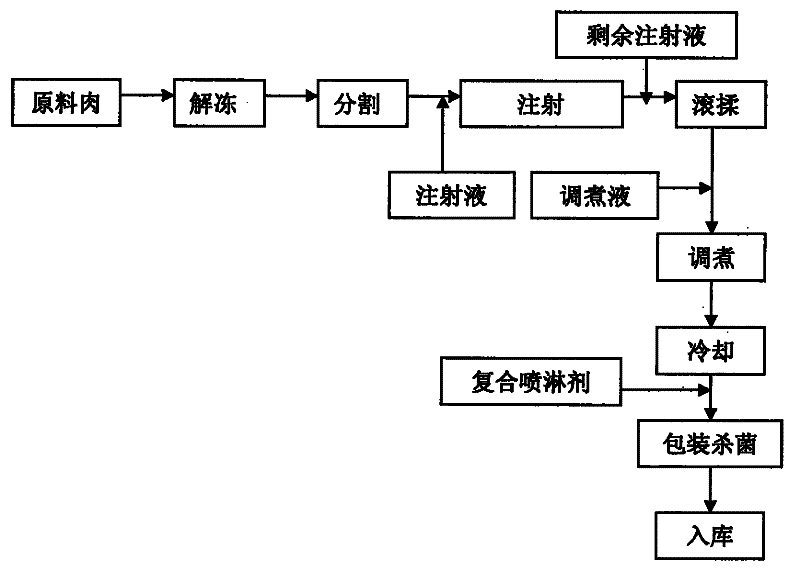

Method used

Image

Examples

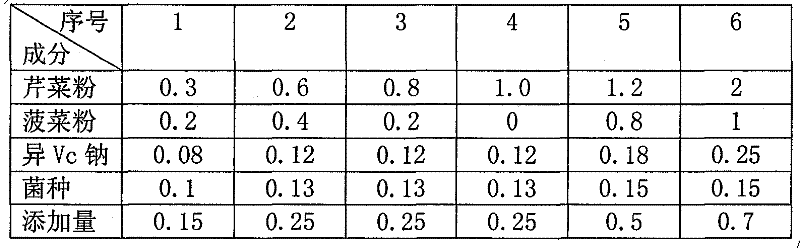

Embodiment 1

[0056] Compound pickling preparation: 0.8kg of celery powder, 0.2kg of spinach powder, 0.13kg of nitrate-reducing bacteria, 0.12kg of iso-VC sodium and 0.375kg after mixing;

[0057] The composite spraying agent is an aqueous solution containing 0.08% tea polyphenol and 1% sodium lactate.

[0058] Based on 100kg raw meat

[0059] Preparation of spice water: Add 250g of spices (star anise, cinnamon, pepper, licorice, tangerine peel, clove) into 50kg of water, boil on high heat, simmer on low heat, filter out the residue, and prepare 28kg of spice water.

[0060] Ratio of injection: 14kg spice water, 2.5kg salt, 2kg white sugar, 0.1kg carrageenan, 0.2kg protein powder: 0.2kg, 0.2kg monosodium glutamate, 0.2kg compound phosphate, 0.5kg glucose, 0.375 compound salting agent kg, ice water 36kg.

[0061] Pretreatment of injection liquid: before injection, the injection liquid (except strains) needs to be homogenized by a homogenizer. After homogenization, the strains and feed liqu...

Embodiment 2

[0065] Compound pickling preparation: 1.2kg of celery powder, 0.4kg of spinach powder, 0.08kg of nitrate-reducing bacteria, 0.08kg of iso-VC sodium and 0.45kg after mixing;

[0066] The composite spraying agent is an aqueous solution containing 0.15% tea polyphenols and 2% sodium lactate.

[0067] Based on 100kg raw meat

[0068] Preparation of spice water: Add 250g of spices (star anise, cinnamon, pepper, licorice, tangerine peel, clove) into 50kg of water, boil on high heat, simmer on low heat, filter out the residue, and prepare 28kg of spice water.

[0069] Ratio of injection: 14kg spice water, 2.5kg salt, 2kg white sugar, 0.1kg carrageenan, 0.2kg protein powder: 0.2kg, 0.2kg monosodium glutamate, 0.2kg compound phosphate, 0.5kg glucose, 0.45 compound salting agent kg, ice water 36kg.

[0070] Pretreatment of injection liquid: before injection, the injection liquid (except strains) needs to be homogenized by a homogenizer. After homogenization, the strains and feed liqui...

Embodiment 3

[0074] Compound pickling preparation: celery powder 0.6kg, nitrate-reducing bacteria 0.15kg, iso-VC sodium 0.15kg, take 0.32kg after mixing;

[0075] The composite spraying agent is an aqueous solution containing 0.05% tea polyphenol and 0.7% sodium lactate.

[0076] Based on 100kg raw meat

[0077] Preparation of spice water: Add 250g of spices (star anise, cinnamon, pepper, licorice, tangerine peel, clove) into 50kg of water, boil on high heat, simmer on low heat, filter out the residue, and prepare 28kg of spice water.

[0078]Ratio of injection: 14kg spice water, 2.5kg salt, 2kg white sugar, 0.1kg carrageenan, 0.2kg protein powder: 0.2kg, monosodium glutamate 0.2kg, compound phosphate 0.2kg, glucose 0.5kg, compound salting agent 0.32 kg, ice water 36kg.

[0079] Pretreatment of injection liquid: before injection, the injection liquid (except strains) needs to be homogenized by a homogenizer. After homogenization, the strains and feed liquid are mixed evenly with a mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com