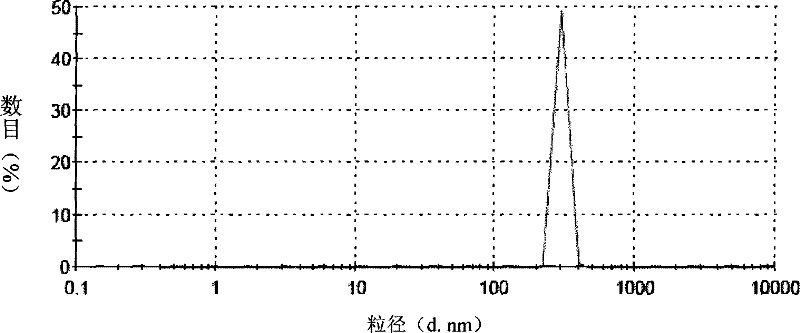

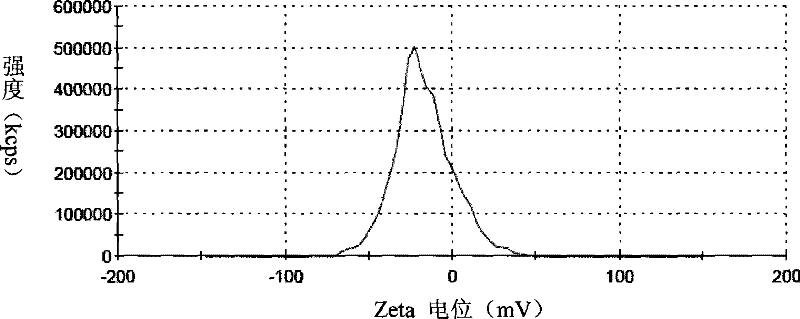

Nanometer lipid sun-prevention microparticle suspending liquid and preparation method thereof

A nano-lipid, suspension technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of coating sunscreens that have not yet been disclosed, and coating cosmetics with few active components, and avoid high pressure. The effect of homogenization, few steps and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Weigh 3.0g monoglyceride, 5.0g PEG-20 sorbitan monooleate, 4.0g caprylic capric triglyceride, 3.0g octyl methyl cinnamate, 2.0g menthyl anthranilate in oil Then weigh 83.0g of distilled water into the water phase beaker, heat the oil phase and the water phase to 85°C respectively, and at the same time homogenize the water phase at 8000 rpm, pour the components of the oil phase into the homogeneous After 2 minutes, start stirring and cooling at a stirring speed of 100 rpm. When the temperature of the system drops to 40°C, add 0.2g of imidazolidinyl urea, then stir and cool to room temperature 25°C.

example 2

[0043] Weigh 2.0g monoglyceride, 5.0g sorbitan monooleate, 2.0g isopropyl palmitate, 2.0g menthyl anthranilate, 4.0g 2-hydroxy-4-methoxybenzophenone In the beaker of the oil phase; then weigh 85.0g of distilled water in the beaker of the water phase, heat the oil phase and the water phase to 90°C respectively, and pour the oil phase components into the water phase at 10,000 rpm while homogenizing, After homogenizing for 3 minutes, start stirring and cooling at a stirring speed of 300 rpm. When the system cools down to 50°C, add 0.2g of phenoxyethanol, then stir and cool to room temperature 30°C.

example 3

[0045] Weigh 2.0g monoglyceride, 4.0g PEG-20 sorbitan monostearate, 4.0g isopropyl palmitate, 4.0g N,N-dimethyl-p-aminobenzoic acid octyl, 2.0g Put 4-methyl-4-ethoxybenzoylmethane in the beaker of the oil phase; weigh 84.0g of distilled water in the beaker of the water phase, heat the oil phase and the water phase to 80°C respectively, and mix at 15000 rpm At the same time as the water phase, pour in the oil phase components, after 4 minutes of homogenization, start to stir and cool, the stirring speed is 600 rpm, when the system cools down to 60°C, add 0.2g of imidazolidinyl urea, and then stir Cool to room temperature 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com