Method for extracting plant extract for preventing and treating diabetes as well as extract product and uses thereof

A technology of plant extracts and extraction methods, which are applied in the directions of plant raw materials, medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, etc., to achieve high preparation safety, no side effects, and no harmful solvent residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

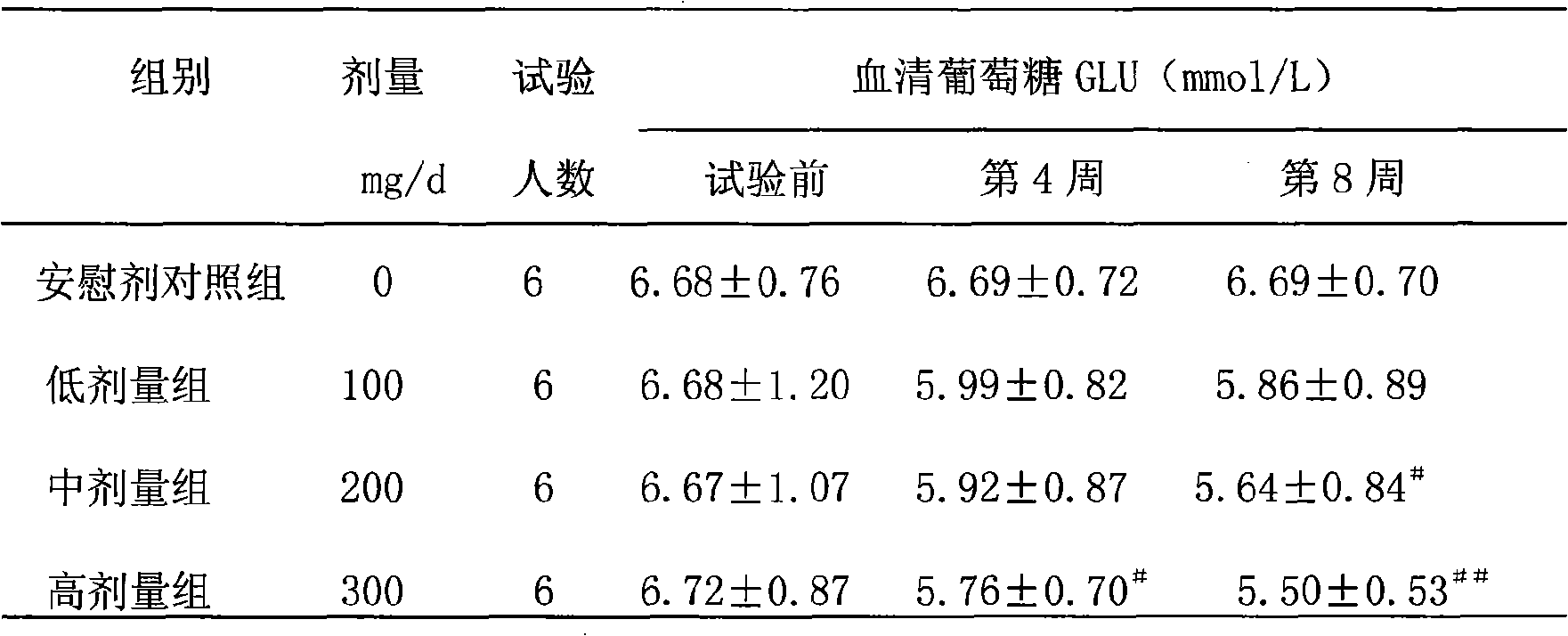

Examples

Embodiment 1

[0048] 100kg of flaxseeds were removed and dehulled to obtain 35kg of flaxseed skins, all of which were pulverized and passed through a 16-mesh sieve, added 140kg of 60% food-grade ethanol solution, stirred continuously at room temperature, extracted for 24 hours, and suction filtered to separate the solid from the liquid. The separated liquid was concentrated under reduced pressure to obtain 4.1 kg of paste, then added 24 kg of sodium hydroxide solution (concentration is pH=13), stirred continuously at room temperature, alkaline hydrolyzed for 12 hours, added hydrochloric acid to adjust to neutral, Then concentrated under reduced pressure twice to 11 kg. The liquid obtained from the secondary concentration was dried by spray drying equipment, the inlet temperature of the drier was 170° C., and the outlet temperature was 70° C., and 2.7 kg of linseed plant extract was obtained. After testing, the weight ratio of flax lignans is 18.4%, ferulic acid is 1.5%, coumaric acid is 1.2...

Embodiment 2

[0050] 100kg of flaxseeds were removed and dehulled to obtain 35kg of flaxseed skins, all pulverized and passed through a 24-mesh sieve, adding 105kg of 70% food-grade ethanol solution, stirring continuously at room temperature, extracting for 18 hours, and separating solid and liquid by suction filtration. Concentrate the separated liquid under reduced pressure to obtain 3.25 kg of paste, add 22 kg of sodium hydroxide lye (concentration is PH13), stir continuously at room temperature, perform alkaline hydrolysis for 15 hours, adjust to neutral with hydrochloric acid, and reduce Concentrate under pressure to obtain 10.2 kg of concentrate, put the above-mentioned secondary concentrate into a spray dryer, the drying inlet temperature is 180°C, and the outlet temperature is 85°C. Obtain 3.1kg plant extract. Among them, the weight ratio of flax lignans was 23.8%, ferulic acid 2.6%, coumaric acid 1.9%, dietary fiber 60.1%, and the rest were impurities accounting for about 11.6%.

Embodiment 3

[0052] 100kg of flaxseeds were removed and dehulled to obtain 35kg of flaxseed skins, all of which were pulverized and passed through a 30-mesh sieve, added 120kg of 80% food-grade ethanol solution, stirred continuously at room temperature, extracted for 12 hours, and suction filtered to separate the solid from the liquid. The separated liquid was concentrated under reduced pressure to obtain 3.6 kg of paste, then added 32 kg of sodium hydroxide solution (concentration is pH=13), stirred continuously at room temperature, alkaline hydrolyzed for 18 hours, added hydrochloric acid to adjust to neutral, Then concentrated under reduced pressure twice to 15 kg. The liquid obtained from the secondary concentration was dried in a spray drier with an inlet temperature of 240° C. and an outlet temperature of 100° C. to obtain 3.4 kg of linseed plant extract. After testing, the weight ratio of flax lignans is 29.6%, ferulic acid is 3.9%, coumaric acid is 2.8%, dietary fiber is 51.5%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com