Al-pillared paligorskite modified solid acid catalyst and preparation and application thereof

A technology of solid acid catalyst and palygorskite, which is applied in the chemical industry, can solve the problems of large consumption of n-octanol, high reaction temperature, and poor thermal stability, and achieve good catalytic effect, no pollution to the environment, and low raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

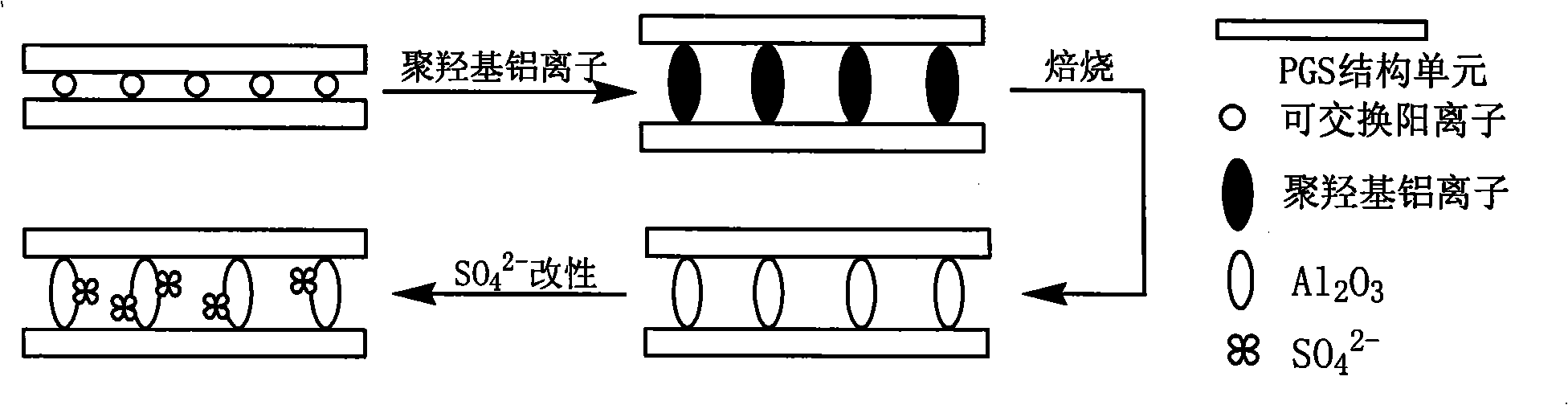

[0060] Embodiment 1, SO 4 2- Preparation of / Al-PGS solid acid catalyst

[0061] ① At a concentration of 0.2-0.3mol / L AlCl 3 Add NaOH solution to the solution to make Al and OH in the mixture - The molar ratio is 1:2.2~1:2.5, the temperature is controlled at 70~90°C, and the aging is stirred for 18~36 hours to obtain the polyhydroxyaluminum ion solution;

[0062] ② Prepare the purified palygorskite into a slurry with a mass fraction of 0.8-1.5%, stir for 1-1.5 hours, and let it stand for 20-30 hours to fully soak and delaminate to make a suspension; add polyhydroxyl Aluminum ion solution, make Al / PGS at 5-8mmol / g, control the temperature at 70-90°C, stir for 20-26h, and centrifuge, the obtained solid is washed with distilled water and centrifuged until the supernatant is washed with AgNO 3 detect no Cl - ;Dry at 70-80°C, grind, pass through a 100-mesh sieve, and then roast at a constant temperature of 450-550°C for 3-5 hours to make pillared clay;

[0063] ③Slowly add H ...

Embodiment 2

[0064] Example 2, SO 4 2- Synthesis of Trioctyl Citrate Catalyzed by Al-PGS Solid Acid Catalyst

[0065] Add citric acid and n-octanol with a molar ratio of 1:4.5 to a two-necked flask with a water separator and a condenser, mix and heat to 80-100°C and reflux for 10-15 minutes while stirring, when the citric acid is completely dissolved , measure the initial acid value of the mixed solution; add citric acid mass 10.5% SO in the mixed solution 4 2- / Al-PGS catalyst, control the temperature at 150°C, react for 6 hours, and separate the water produced by the reaction in time. After the reaction, take the reaction solution to measure the acid value, and calculate the esterification rate of trioctyl citrate: 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com