Method for preparing square tungsten-yttrium blank

A technology of yttrium nitrate and ammonium paratungstate, which is applied in the direction of coating, etc., can solve the problems of poor control, uneven volatilization of tungsten yttrium billets, and uneven volatilization of tungsten yttrium billets, so as to ensure performance, increase welding penetration, and fracture The effect of arc rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

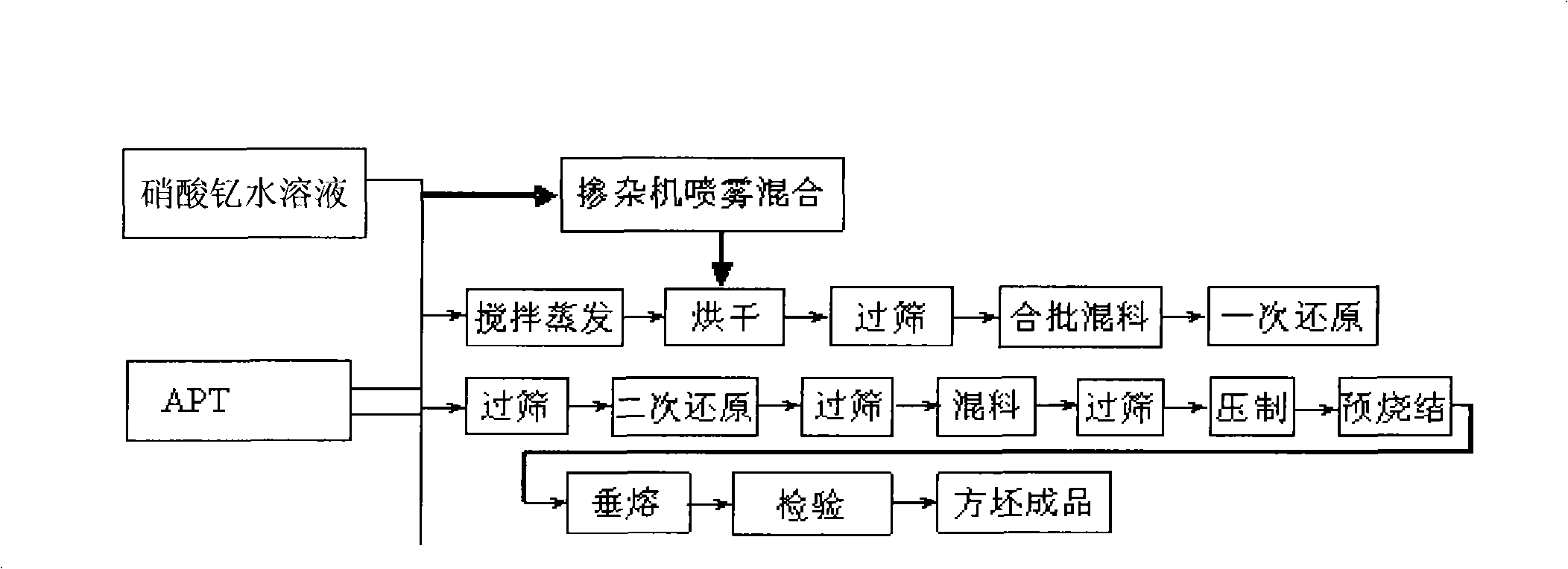

[0023] The embodiment of the present invention provides a method for preparing a tungsten yttrium billet: a tungsten yttrium billet with good uniformity can be prepared, and the processing flow of the method is as follows figure 1 shown, including:

[0024] a. Mix yttrium nitrate and water to make an aqueous solution of yttrium nitrate with a concentration of 0.8-1.8g / ml, and spread the ammonium paratungstate APT surface coated in the doper evenly by spraying at a flow rate of 22-25ml / min At the same time, the ammonium paratungstate (APT) mixed with the yttrium nitrate aqueous solution is heated, dried, mixed and stirred, and the tungsten-yttrium coated powder is obtained after drying; wherein, the heating, drying, mixing and stirring is specifically performed by using steam at a temperature of 100-105 ° C to mix the The stirred yttrium nitrate aqueous solution and ammonium paratungstate (APT) are heated and dried with a steam pressure of 0.3Mpa. After 0.8 to 1 hour, the tempe...

Embodiment 2

[0030] The present embodiment provides a kind of preparation method of tungsten yttrium billet, specifically as follows:

[0031] Preparation of tungsten yttrium coated powder:

[0032] The yttrium tungsten coating is prepared by mixing yttrium nitrate and water with a concentration of 1.5g / ml yttrium nitrate aqueous solution and solid raw material APT, and mixing and doping in a doping machine by spraying and heating and drying. Powder, specifically:

[0033] (1) 24.6 kilograms of yttrium nitrate are dissolved with deionized water to make concentration be the yttrium nitrate aqueous solution of 1.5g / ml;

[0034] (2) 450Kg APT is put into the doping machine and the configured yttrium nitrate aqueous solution is sprayed into the doping machine to coat the APT surface, and mixed and stirred for doping;

[0035] (3) Control the injection flow rate: 22-24ml / min, and the injection time: 40 minutes to 60 minutes;

[0036] (4) Continue to stir for about 20 minutes after spraying t...

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of tungsten yttrium billet, specifically as follows:

[0040] Preparation of tungsten-yttrium coated powder: using yttrium nitrate aqueous solution prepared from yttrium nitrate and solid raw material APT, the tungsten-yttrium coated powder prepared by doping in the doping machine, spray drying and other processes, specifically:

[0041] Dissolve 23 to 24 kg of yttrium nitrate in deionized water to make an aqueous solution of yttrium nitrate with a concentration of 1.7 g / ml. In practice, the concentration of the aqueous solution of yttrium nitrate can also be in accordance with the requirements of the yttrium tungsten billet corresponding to the prepared tungsten yttrium electrode grade to prepare;

[0042] Put 450Kg APT into the doping machine and spray the prepared yttrium nitrate aqueous solution into the doping machine to cover the surface of APT. When spraying, use vacuum equipment to disperse the yttrium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com