Packaging technique for solid electrolyte capacitor

A technology of solid electrolysis and capacitors, which is applied in the direction of solid electrolytic capacitors, capacitor shells/packages, capacitor parts, etc., can solve the problems of dielectric film defects on the surface of the anode body, increased leakage current of capacitors, and large mechanical damage. Leakage current pass rate, quality assurance, and effects of avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

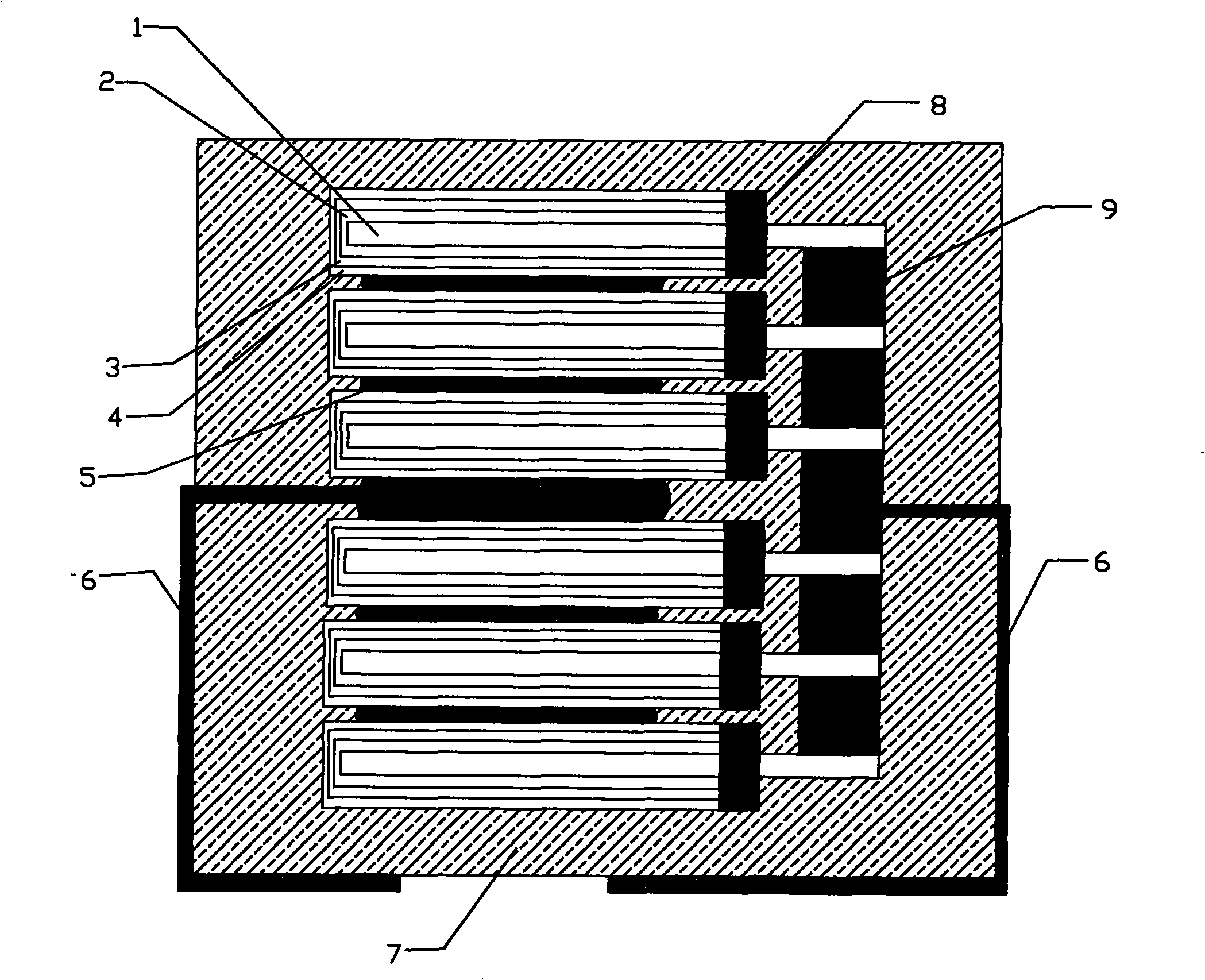

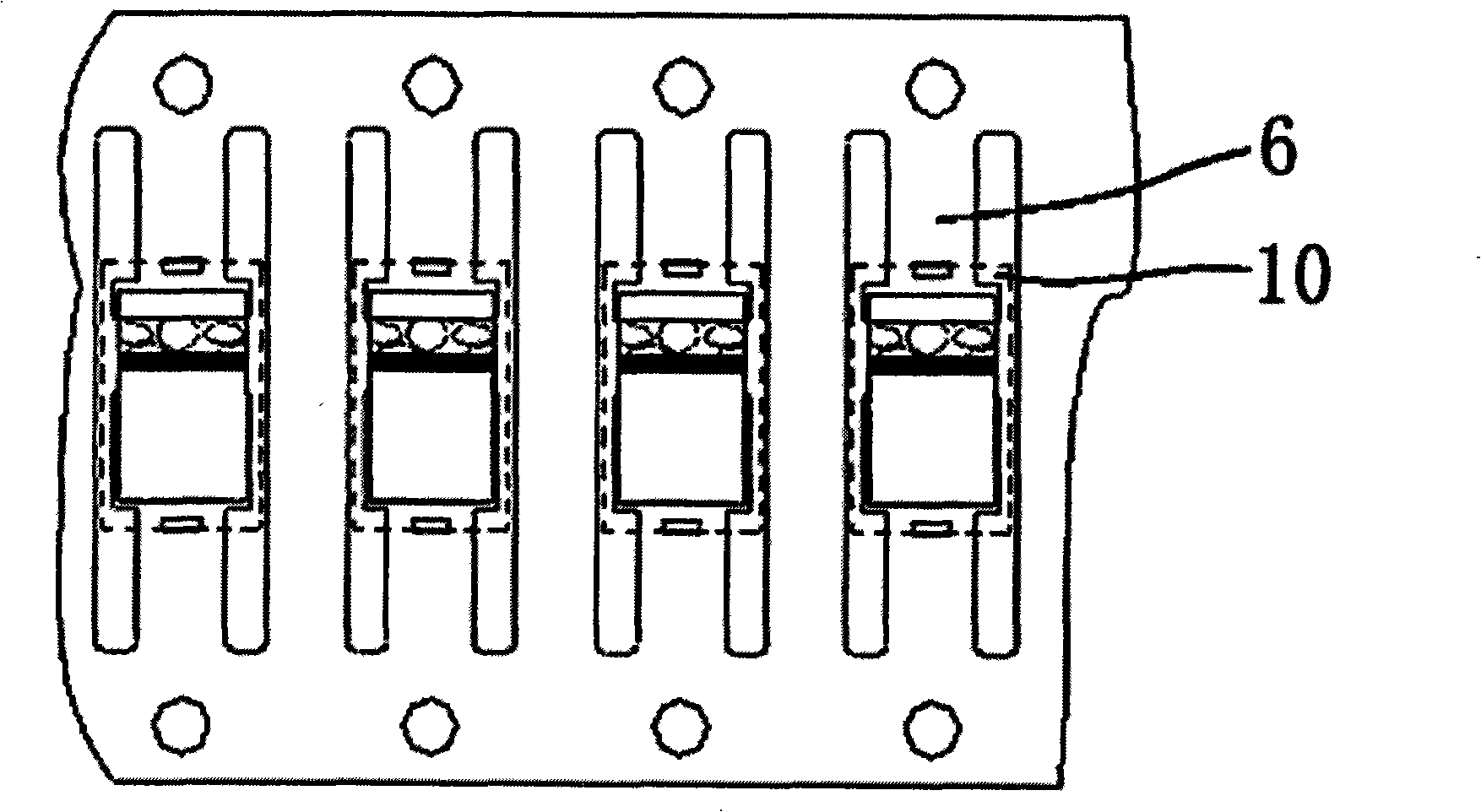

[0017] The 13V aluminum foil with the energizing voltage is cut and welded to the iron craft bar. After processing and forming the cutting edge, the solid electrolyte layer composed of polypyrrole, the cathode lead-out layer composed of carbon layer and silver layer are sequentially produced. Get the capacitor core. Then, a plurality of chips are placed on the lead frame by welding and bonding. Finally, place them in the cavity of an injection molding mold at 125°C, inject a liquid resin with a viscosity of 20,000mpa·s and a curing hardness of 100shoreD at 0.3MPa for 10 seconds, and keep it for 60 seconds to cure it into a package shell. into 6.3V solid aluminum electrolytic capacitors, followed by aging screening. The viscosity of liquid resin is relatively high at normal temperature, but the viscosity drops sharply at high temperature, so there is no problem in the formation of low-pressure injection.

Embodiment 2

[0019] During the injection molding, place it in the cavity of an injection molding mold at 150°C, inject a liquid resin with a viscosity of 45000mpa·s and a curing hardness of 120shoreD at 0.5MPa for 5 seconds, and keep it for 180 seconds to cure it into a package The shell is made into a 6.3V solid aluminum electrolytic capacitor, and the others are the same as in Embodiment 1

Embodiment 3

[0021] During the injection molding, place it in the cavity of an injection molding mold at 180°C, inject a liquid resin with a viscosity of 45,000mpa·s and a curing hardness of 120shoreD at 1MPa for 5 seconds, and keep it for 180 seconds to cure it into a package shell , make a 6.3V solid aluminum electrolytic capacitor, others are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com