Preparation of high-purity tin diselenide nano-plate

A technology for tin diselenide and nanosheets, which is applied in the field of preparation of tin diselenide nanosheets synthesized by hydrothermal method, can solve the problems such as insufficient purity of the nanosheets, and achieves good dispersibility, uniform shape, and safe process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

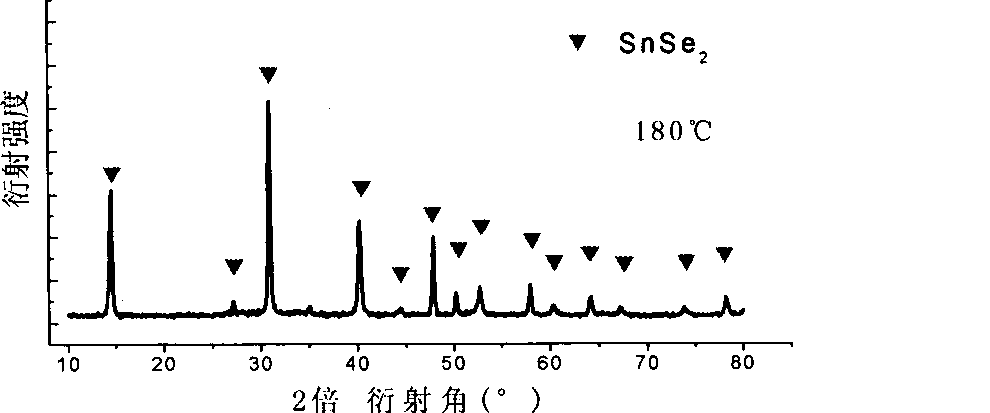

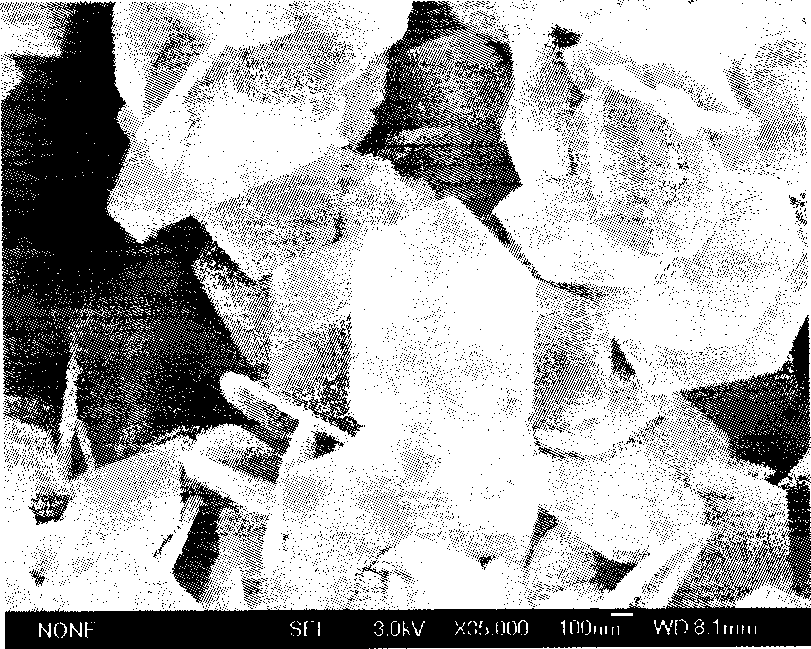

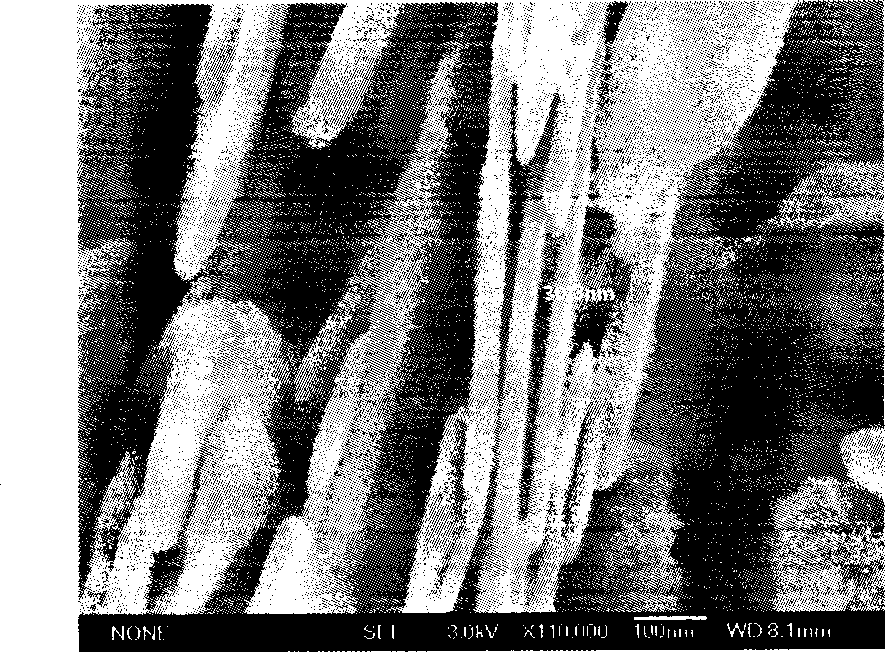

Embodiment 1

[0024] 1.0 parts of SnCl 2 2H 2 O, 0.984 parts of SeO 2 , 0.210 parts of NaOH three solid powders were evenly mixed, and then 12 parts of deionized water were added, and the method of ultrasonic vibration and stirring was used to make them evenly mixed. The above mixture solution was poured into a polytetrafluoroethylene-lined autoclave, and then 0.95 parts of 85% hydrazine and 1.2 parts of 17% ammonia water were added. Heat the above-mentioned reaction tank to 180°C for 20 hours, then cool to room temperature and take it out. The reacted solution is filtered through a water-based microporous membrane, repeatedly washed with deionized water and absolute ethanol, filtered and separated to remove impurities, and washed until neutral. The obtained product after the above washing was dried in a vacuum oven at 70° C. to obtain tin diselenide powder. After detection, the obtained SnSe 2 The purity is 100%.

Embodiment 2

[0026] 0.8 parts of SnCl 2 2H 2 O, 0.787 parts of SeO 2 , 0.280 parts of NaOH three solid powders were evenly mixed, and then 14 parts of deionized water were added, and the method of ultrasonic vibration and stirring was used to make them uniformly mixed. The above mixture solution was poured into a polytetrafluoroethylene-lined autoclave, and then 1.9 parts of 80% hydrazine and 0.80 parts of 20% ammonia water were added. Heat the above reaction tank to 160°C, keep it warm for 24 hours, then cool to room temperature and take it out. The reacted solution is filtered through a water-based microporous membrane, repeatedly washed with deionized water and absolute ethanol, filtered and separated to remove impurities, and washed until neutral. The obtained product after the above washing was dried in a vacuum oven at 50° C. to obtain tin diselenide powder. After detection, the obtained SnSe 2 The purity is 99.5%.

Embodiment 3

[0028] 1.2 parts of SnCl 2 2H 2 O, 1.18 parts of SeO 2 , 0.400 parts of NaOH three solid powders were evenly mixed, and then 16 parts of deionized water were added, and the method of ultrasonic vibration and stirring was used to make them uniformly mixed. The above mixture solution was poured into a polytetrafluoroethylene-lined autoclave, and then 1.5 parts of 85% hydrazine and 1.6 parts of 15% ammonia water were added. The above reaction tank was heated to 200°C for 16 hours, then cooled to room temperature and taken out. The reacted solution is filtered through a water-based microporous membrane, repeatedly washed with deionized water and absolute ethanol, filtered and separated to remove impurities, and washed until neutral. The obtained product after the above washing was dried in a vacuum oven at 80° C. to obtain tin diselenide powder. After detection, the obtained SnSe 2 The purity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com