Method for separating isobutyl acetate, ethanol and water by azeotropic distillation

A technology of isobutyl acetate and isobutyl acetate ternary azeotrope, which is applied in the field of ethanol, water, and azeotropic distillation to separate isobutyl acetate, can solve the problem of increased loss of enterprises, waste of chemical raw materials, and increased operating costs and other issues to achieve the effect of reducing secondary investment, increasing yield, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

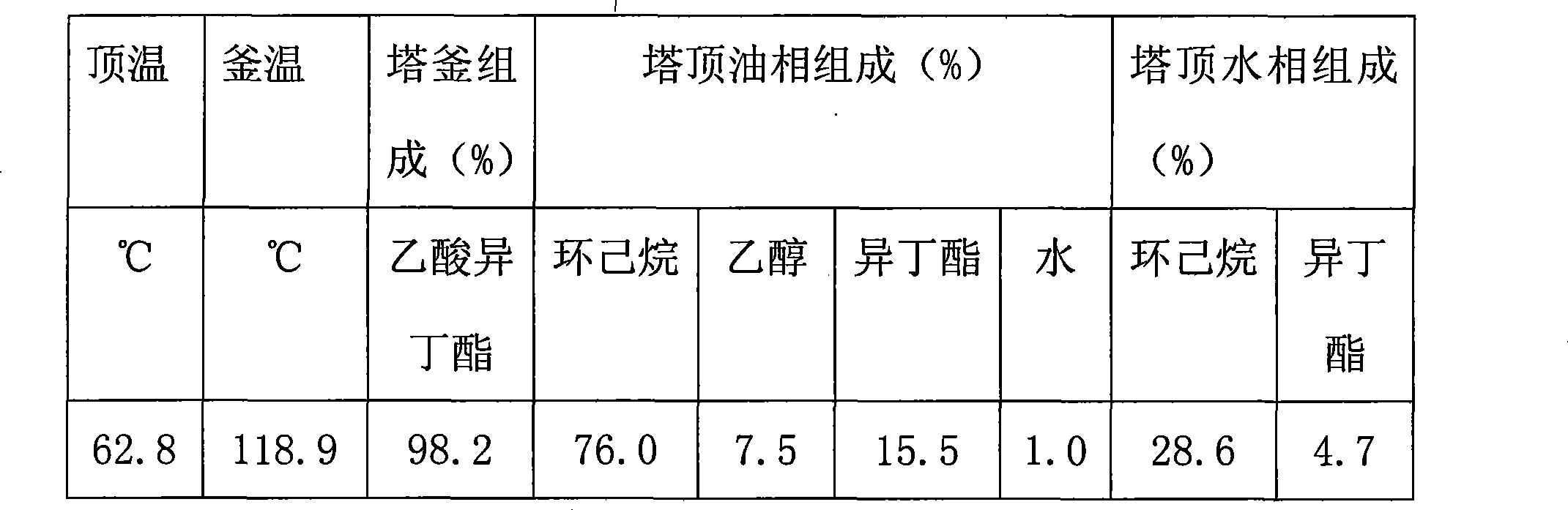

[0017] Embodiment 1, a kind of method of azeotropic rectification separation isobutyl acetate, ethanol, water is to adopt two-tower type continuous rectification process, is to feed the mixed solution of isobutyl acetate, ethanol, water from the middle part of the tower , the entrainer enters the upper part of the azeotropic distillation column, the mass ratio of the dose of the entrainer to the isobutyl acetate ternary azeotrope is 0.5~1.2:1, and the entrainer can be cyclohexane, n-hexane and benzene One of them, the present embodiment adopts cyclohexane, and the added entrainer forms a ternary azeotrope with ethanol and water in the azeotropic rectification tower, and the isobutyl acetate is extracted from the bottom of the azeotropic rectification tower The product, the ternary azeotrope enriched with entrainer, ethanol, and water at the top of the tower, is condensed and separated to form an oil phase and a water phase. The oil phase is used as the reflux liquid of the azeo...

Embodiment 2

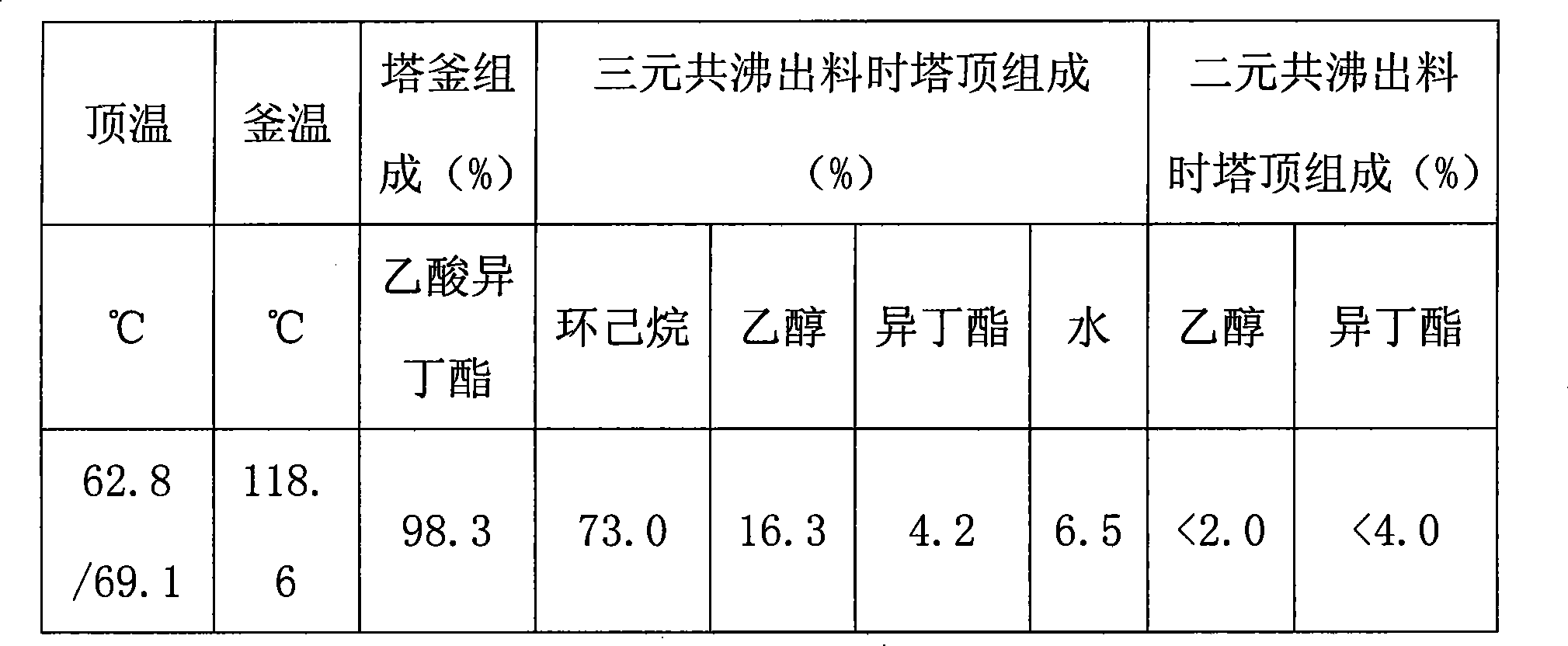

[0020] Embodiment 2, a kind of azeotropic distillation separates the method for isobutyl acetate, ethanol, water, is to adopt two-tower type intermittent rectification process, is the ternary co-aeration of entrainer and isobutyl acetate, ethanol, water Boilers are added to the batch azeotropic rectification column together, wherein the mass ratio of isobutyl acetate, ethanol, water: entrainer is 0.5~1.6:1, entrainer can be cyclohexane, n-hexane and benzene One of them, cyclohexane is used in this embodiment, the condensate from the top of the tower is condensed by the condenser, the oil phase flows back into the tower as the reflux liquid of the intermittent azeotropic distillation tower, and the water phase material is extracted to the corresponding storage tank Inside, the isobutyl acetate product is extracted from the tower kettle, and the entrainer, ethanol, and water ternary azeotrope extracted from the top of the intermittent azeotropic distillation tower are pumped into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com