Formula and preparation of biocatalyst for modification and improvement of petroleum fuel oil

A biocatalyst, fuel oil technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of reducing viscosity value, improving combustion efficiency, and improving equipment operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

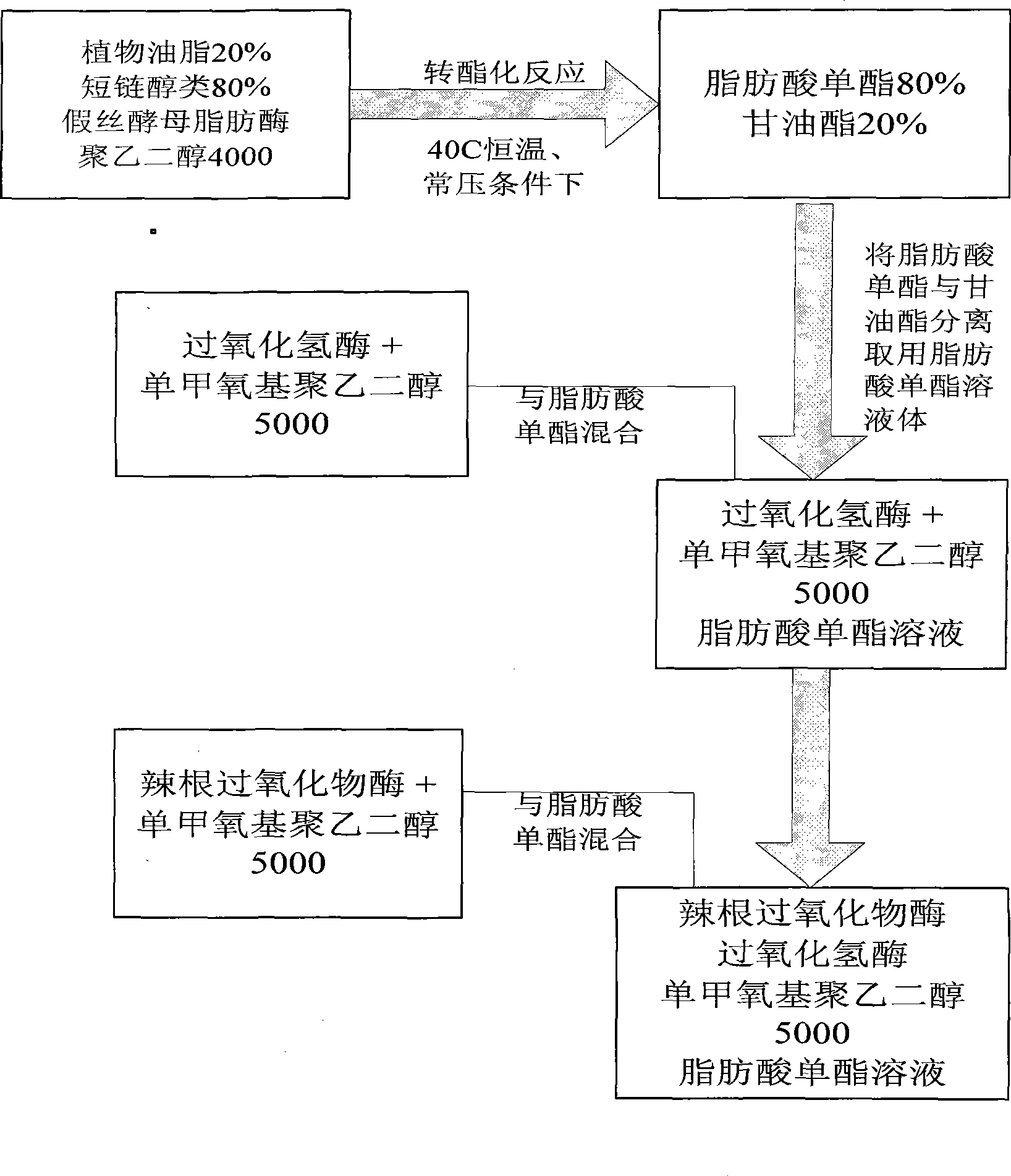

[0013] A biocatalyst used for the modification and improvement of petroleum fuel oil. Its main ingredients are: 1. Vegetable oil; 2. Methanol; 3. Bioethanol; 4. Candida lipase; 5. Horseradish peroxidase; 6. Catalase; 7. Polyethylene glycol 1000 ~5000 (abbreviation: PEG); 8. Monomethoxypolyethylene glycol 5000~10000; (abbreviation: MPEG). According to the example of one-time production of 1,000 liters of biocatalyst products for petroleum fuel oil upgrading and improvement, the preparation of raw materials, the production process steps and the proportion of raw materials used are as follows:

[0014] 1. The first step: use "biogenerator" equipment to produce "fatty acid methyl ester or ethyl ester"; when producing biocatalysts for gasoline, use bioethanol as raw material to generate fatty acid ethyl ester; produce diesel oil and heavy oil When using methanol as a biocatalyst, methanol is used as a raw material to generate fatty acid methyl esters (collectively referred to as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com