Synthesis of ion imprinted polymer particle

An ion imprinting, polymer technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of uncommon separation and contact with inorganic ions, and no separation is involved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

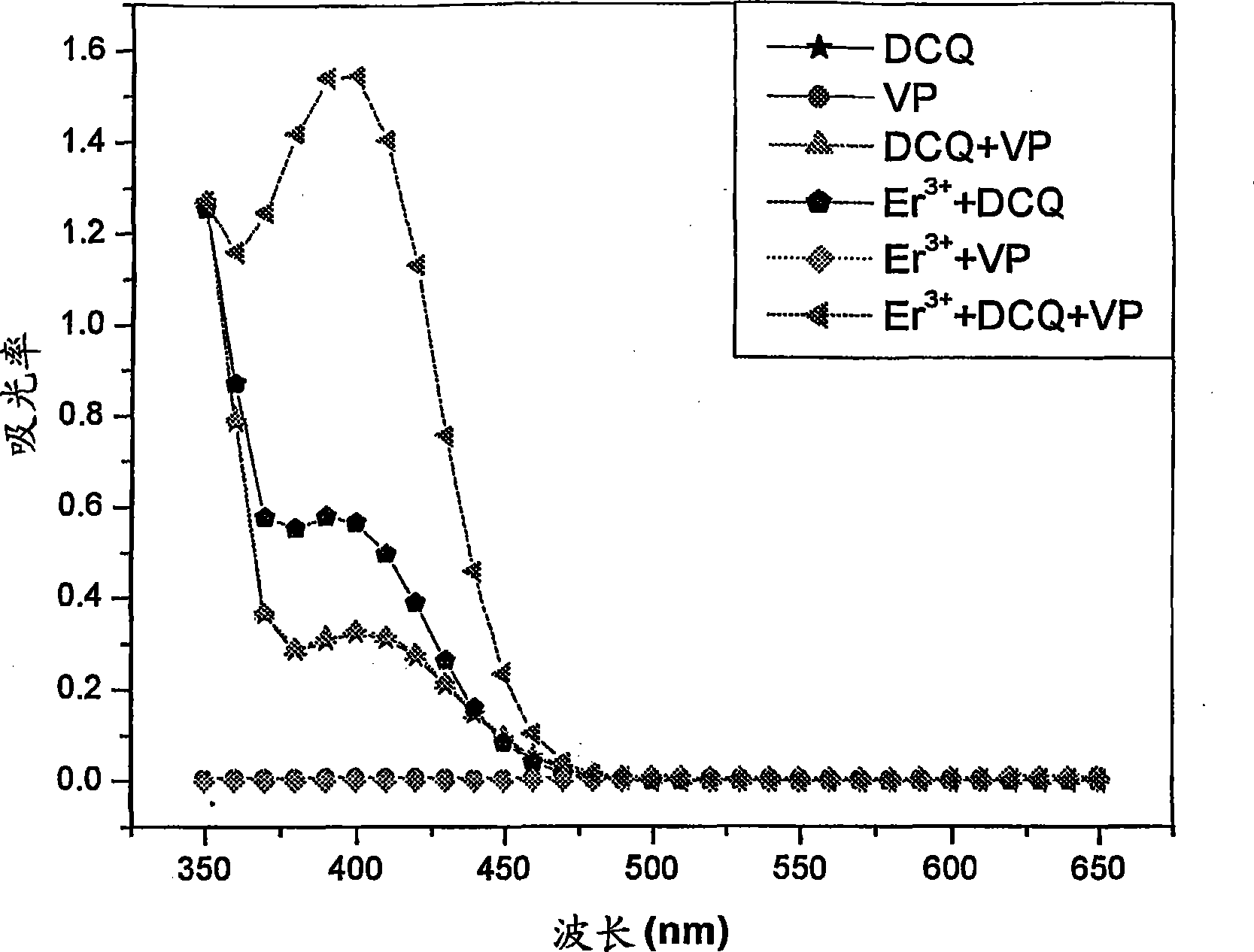

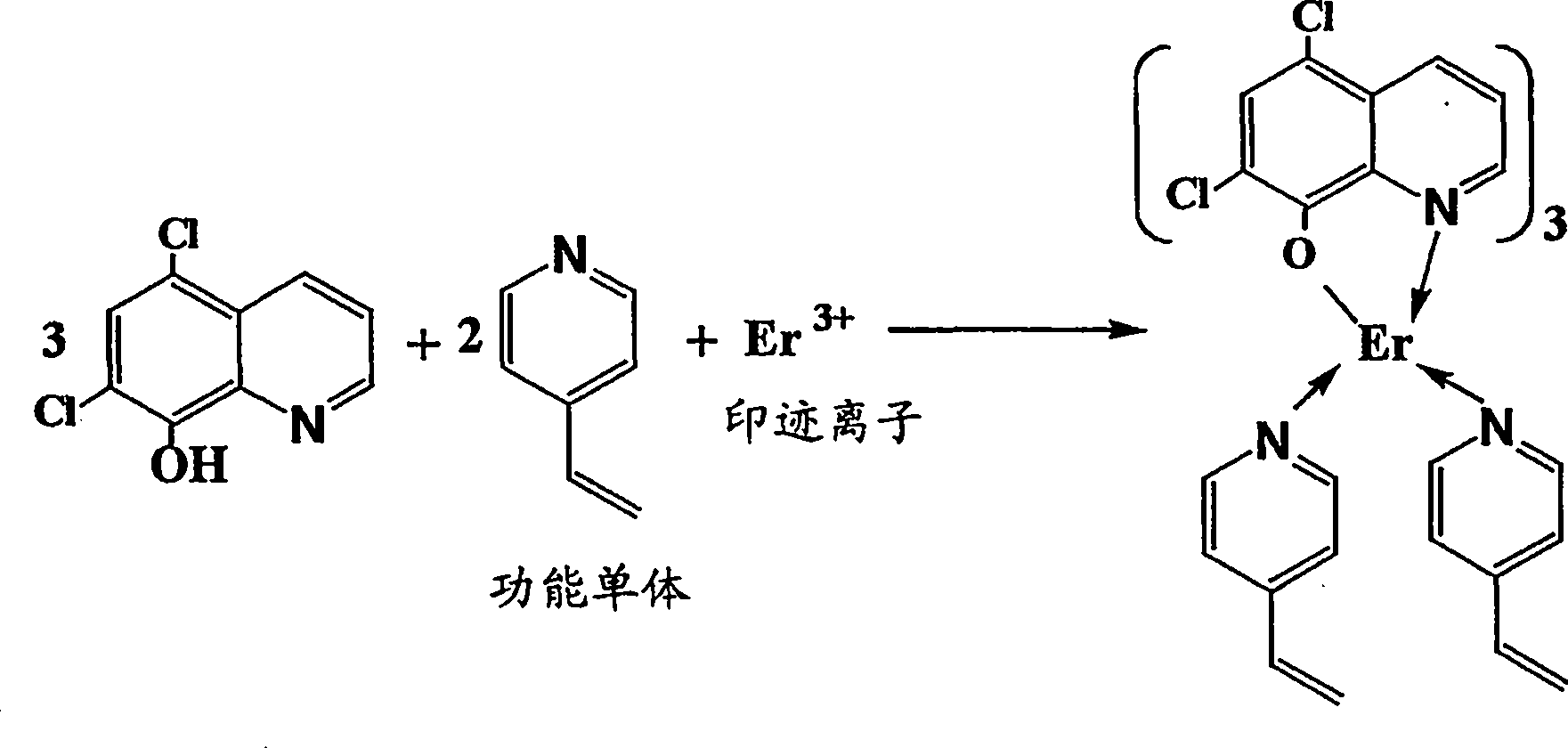

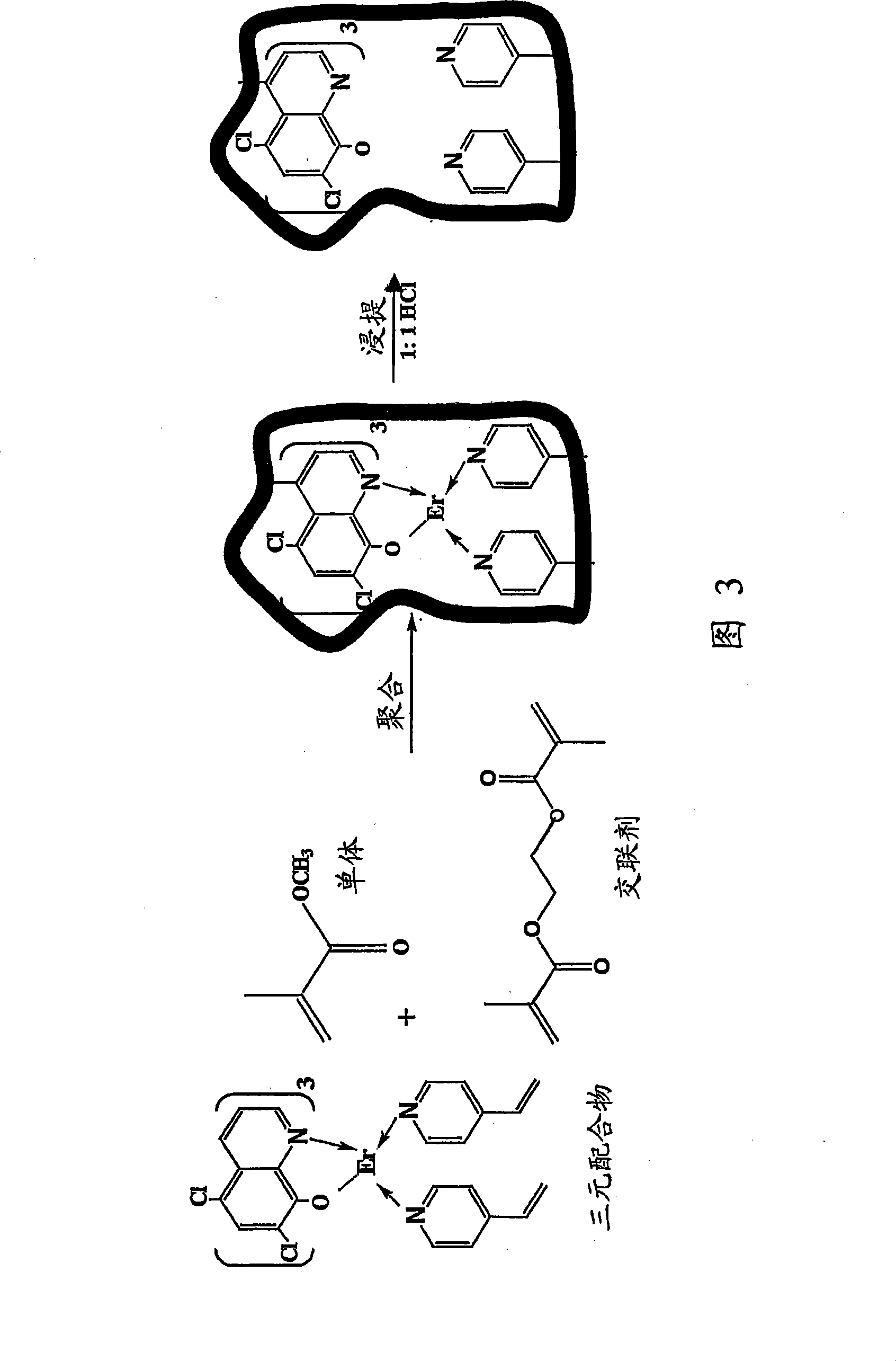

[0061] Example 1: Gamma-radiation polymerization

[0062] In a 50ml round bottom flask, 1.0mM Erbium chloride (0.44g), 3.0mM DCQ (0.64g) and 2mM VP (0.21g) were added and dissolved in 5 or 10ml 2-methoxyethanol with stirring. 4 (0.4g) or 8 (0.8g) and 12 (1.2g) mM MMA and 16 (3.17g) or 32 (6.34g) and 48 (9.52g) mM EGDMA were added and stirred until a homogeneous solution was obtained. Transfer the monomer mixture to a test tube, cool to 0°C, and 2 Purge for 10 minutes and seal.

[0063] Application Co 60 source, these solutions were irradiated for 4 hours under 1 M Rad gamma-irradiation. The solid formed was washed with water and dried in an oven at 50°C. 5.70, 9.43 and 14.27 g of polymeric material were obtained with 4, 8 and 12 mM functional monomer, respectively. The polymer intercalating the erbium ions was leached with 50% (v / v) HCl while stirring for 6 hours. After drying in an oven at 50°C, 4.14, 7.52 and 11.29 g of polymeric material were obtained with 4, 8 and 12...

Embodiment 2

[0064] Embodiment 2: photochemical method polymerization

[0065] In a 50ml round bottom flask, 1.0mM Erbium chloride (0.44g), 3.0mM DCQ (0.64g) and 2.0mM VP (0.21g) were added and dissolved in 10ml of 2-methoxyethanol with stirring. 8mM MMA (0.8g), 32mM EGDMA (6.35g) and 50mg AIBN were added and stirred until a homogeneous solution was obtained. Transfer the monomer mixture to a test tube, cool to 0°C, and 2 Purge for 10 minutes and seal. These solutions were polymerized by UV radiation (300 nm) for 4, 8 and 16 hours. The solid formed was washed with water and dried in an oven at 50°C. 7.55, 9.85 and 9.95 g of polymer material were obtained with UV radiation (300 nm) for 4, 8 and 16 h. The polymer intercalating the erbium ions was leached with 50% (v / v) HCl while stirring for 6 hours. After drying in an oven at 50° C., 5.35, 7.31 and 7.36 g of polymeric material were obtained after UV irradiation for 4, 8 and 16 h, respectively.

Embodiment 3

[0066] Example 3: thermal polymerization

[0067] In a 50ml round bottom flask, 1.0mM Erbium chloride (0.44g), 3.0mM DCQ (0.64g) and 2.0mM VP (0.21g) were added and dissolved in 10ml of 2-methoxyethanol with stirring. 8.0 mM MMA (0.8 g), 8, 16 and 32 mM EGDMA (1.59, 3.17 and 6.34 g) and 50 mg AIBN were added and stirred until a homogeneous solution was obtained. The polymerization mixture was cooled to 0 °C with N 2 Purge for 10 minutes, seal and heat and stir in an oil bath at about 80°C for 2 hours. The solid formed was washed with water and dried in an oven at 50°C. 4.32, 5.50 and 8.84 g of polymer material were obtained with 50%, 66% and 80% crosslinking monomer. The polymer intercalated with erbium ions was extracted with 100 ml of 50% (v / v) HCl, stirred for 6 hours, filtered, and dried in an oven at 50°C. 2.59, 3.90 and 7.90 g of erbium ion imprinted polymer material were obtained.

[0068] Advantages of the present invention:

[0069] Liquid-liquid extraction meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com