Gas-stripping internal circulation filter and liquid membrane filter method

A membrane filter, internal circulation technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of broken wires, affecting membrane filtration flux, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

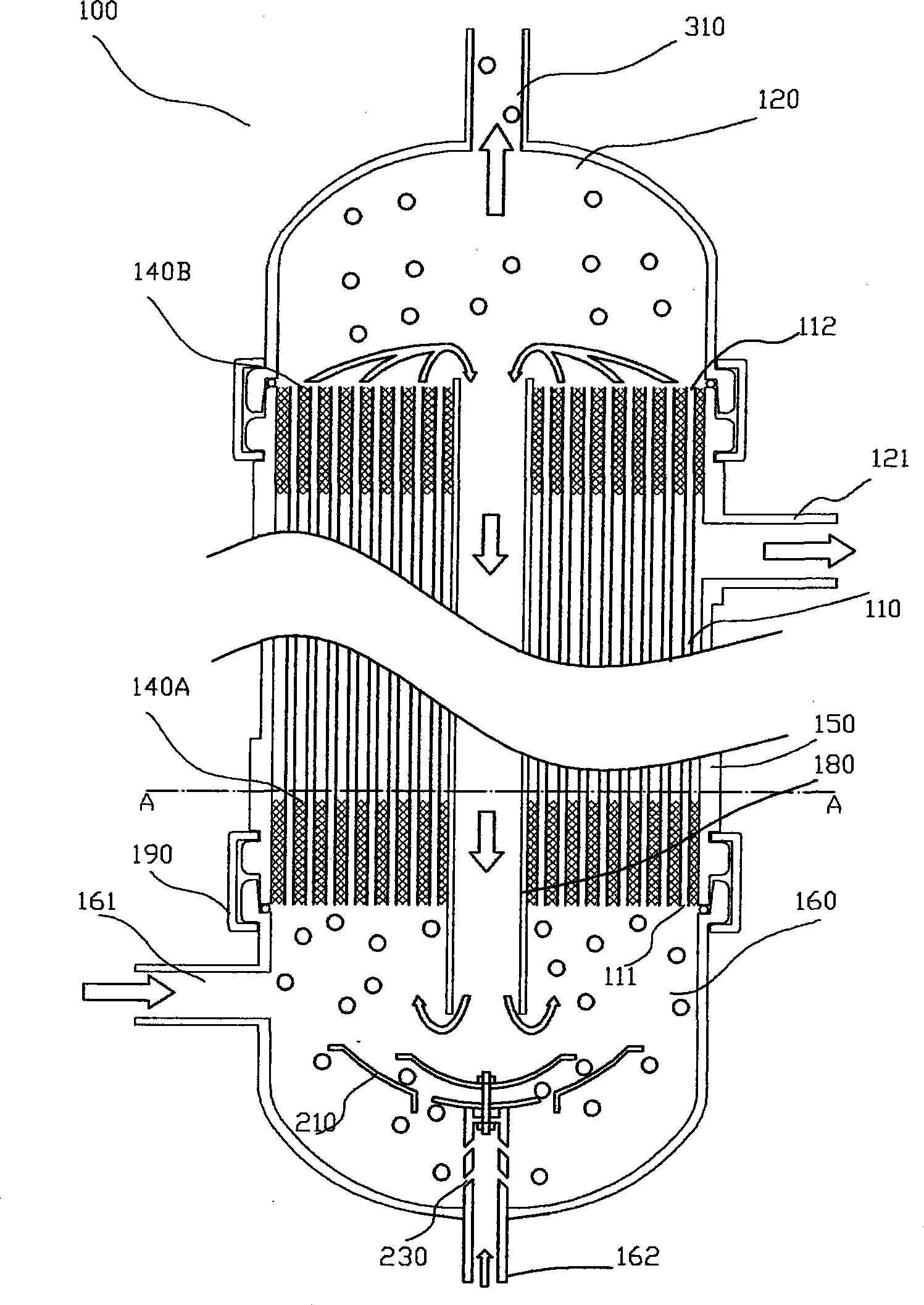

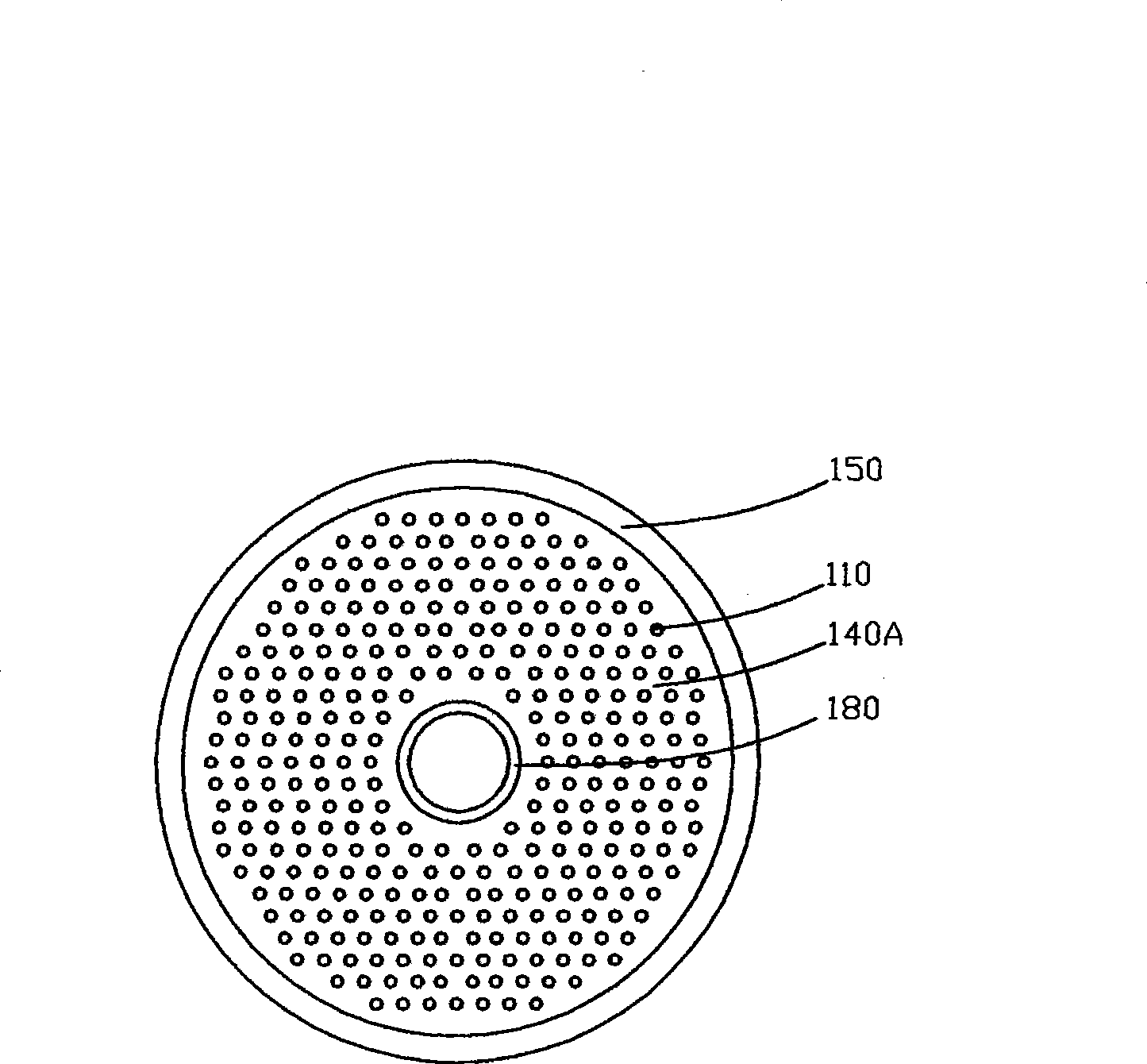

Embodiment 1

[0041] Embodiment 1: as Figure 7 As shown, in the internal pressure airlift internal circulation membrane filter, the outer diameter of the shell 150 is 250mm, the inner diameter of the capillary 110 is 1.2mm, the outer diameter is 1.8mm, the length of the capillary 110 is 1.5m, and the number of capillaries is 6300. The liquid return channel 184 is 6 plastic pipes with an inner diameter of 20mm, and the aeration device 211 is a rubber microporous aeration head. This membrane filter is used in a membrane bioreactor. The treated water is domestic sewage, the COD content is 200-500mg / L, and the biochemical sludge content is 3000-4500mg / L.

[0042] Water supply pressure 0.15MPa, product water pressure 0MPa, aeration rate 200L / min; backwash cycle 60 minutes, backwash flow 6m 3 / hr., backwash time 1 minute. Every 24 hours of operation, a chemical enhanced backwash is used. The chemical enhanced backwash uses 200mg / L sodium hypochlorite solution, the chemical enhanced backwash f...

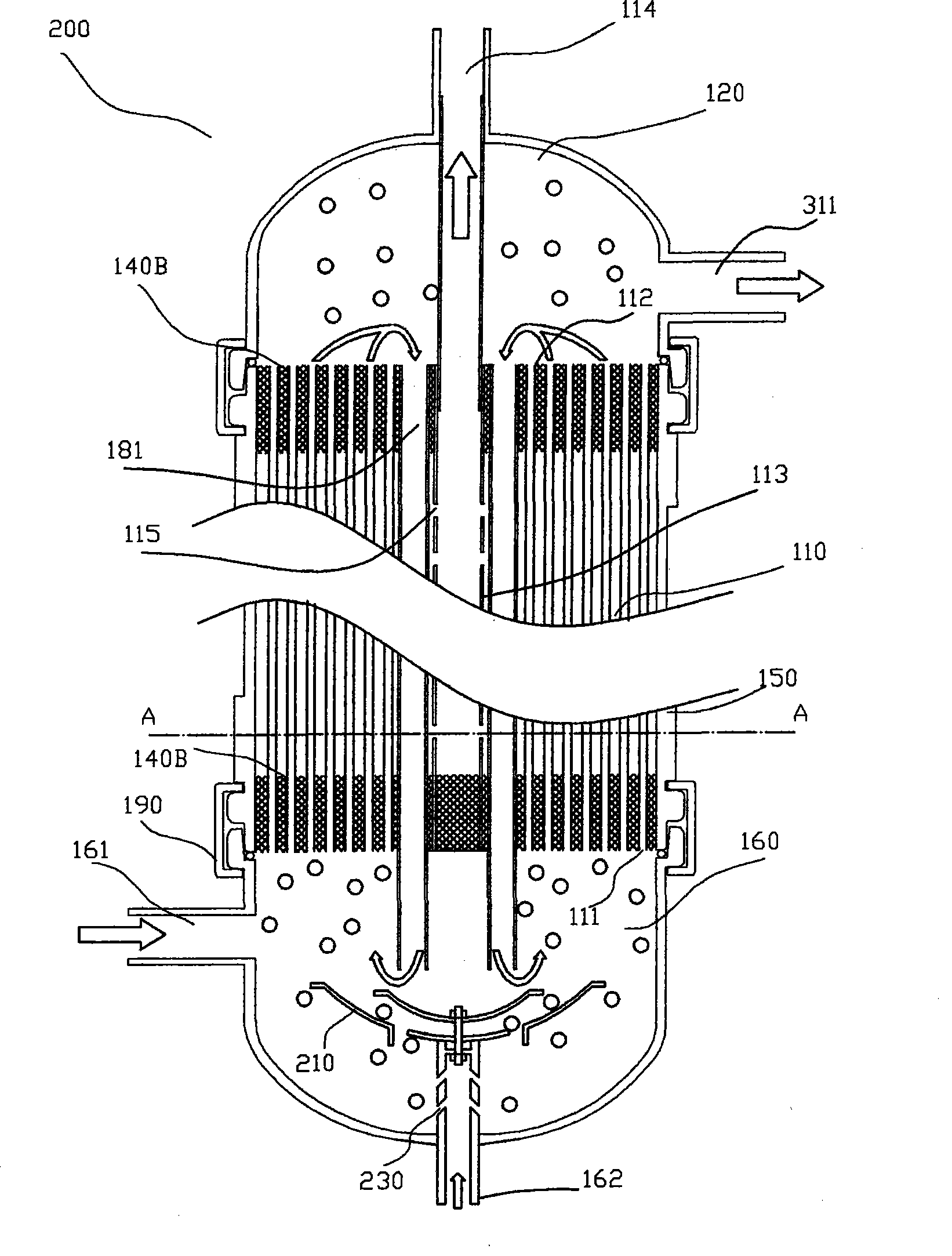

Embodiment 2

[0046] Such as Figure 14 As shown, the external pressure airlift internal circulation membrane filter, the outer diameter of the membrane filter housing 150 is 250mm, the inner diameter of the capillary 110 is 1.2mm, the outer diameter is 1.8mm, the length of the capillary 110 is 1.5m, and the number of capillaries is 5800. The liquid backflow channel 186 is 6 plastic pipes with an inner diameter of 20mm, and the aeration device 211 is a rubber microporous aeration head. This membrane filter is used in a membrane bioreactor. The treated water is domestic sewage, the COD content is 200-500mg / L, and the biochemical sludge content is 3000-4500mg / L.

[0047] Water supply pressure 0.15MPa, product water pressure 0MPa, aeration rate 200L / min; backwash cycle 60 minutes, backwash flow 6m 3 / hr., backwash time 1 minute. Every 24 hours of operation, a chemical enhanced backwash is used. The chemical enhanced backwash uses 200mg / L sodium hypochlorite solution, the chemical enhanced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com