Butanol-octanol waste oil and 2-PH waste oil resource treatment method

A treatment method and a resource-based technology, applied in the field of treatment of butyl-octyl alcohol waste oil and 2PH waste oil, can solve problems such as pollution, difficult treatment and disposal, waste of energy, etc., and achieve a reasonable process route, high product quality, and reasonable construction economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

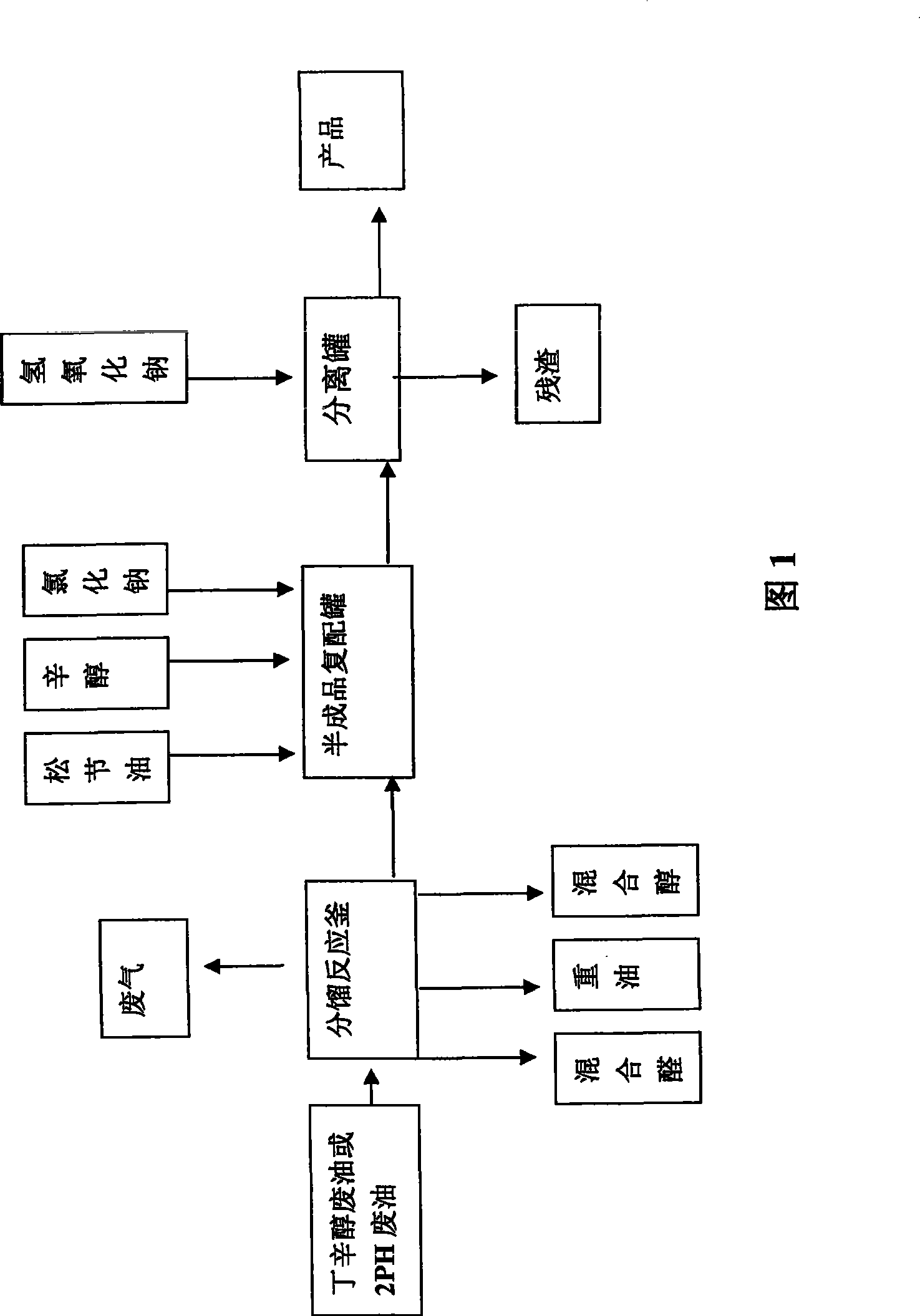

Image

Examples

Embodiment 1

[0030] Put 80 tons of butyl-octyl alcohol waste oil into the rectification reactor, heat it up to 80°C-120°C with steam, fractionate it according to the boiling point of different substances under normal pressure, and send the fractionated fraction to the intermediate tank; among them, the mixed alcohol 11 tons, 13 tons of heavy oil, and gas containing hydrocarbons will be emitted at the same time, and sent to the incinerator for incineration. From the mixed alcohol, 9 tons of n-butanol and 4 tons of isobutanol are obtained, and the heavy oil is mainly C8-C12 alkanes, which can be used as boiler fuel.

[0031] Then add 10 tons of turpentine, 25 tons of octanol and 11 tons of sodium hydroxide to the rectification reaction kettle to participate in the compounding, and control the reaction temperature at about 100°C, keep the normal pressure and constant temperature for 5 to 6 hours, and get the semi-finished product;

[0032] Then send the reaction semi-finished product in the r...

Embodiment 2

[0035] Put 85 tons of 2-PH waste oil into the rectification reactor, heat it with steam to 80°C~120°C, fractionate according to the boiling point of different substances under negative pressure (-0.095KPa), and send the fractionated fraction to the intermediate tank; 11.5 tons of mixed alcohol and 13.2 tons of heavy oil will be obtained by fractional distillation. At the same time, gas containing hydrocarbons will be discharged and sent to the incinerator for incineration.

[0036] Then add 11 tons of turpentine, 28 tons of octanol and 10 tons of sodium hydroxide to the rectification reaction kettle to participate in the compounding, and control the reaction temperature at about 100°C, keep the normal pressure and constant temperature for 5 to 6 hours, and get the semi-finished product;

[0037] Then send the reaction semi-finished product in the rectification reaction kettle to the semi-finished product separation tank, adjust the pH to 7-8 with 30% sodium hydroxide solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com