Dielectric composite material and preparation method thereof

A composite material and dielectric technology, which is applied to the parts of fixed capacitors and the dielectric of fixed capacitors, can solve the problems of poor machining performance, and achieve the effects of good machining performance, low cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: preparation f Al Al-BaTiO = 0.05 3 / PVDF dielectric composites.

[0035] The preparation steps are as follows:

[0036] (1) According to the volume fraction percentage f Al =0.05,f BaTiO3 =0.20,f PVDF =0.75 Weigh the raw materials, convert the volume fraction into mass and weigh 0.0450g, 0.3900g, 0.4500g in turn.

[0037] (2) Add 0.4500g of PVDF weighed into 40ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0038] (3) BaTiO 3 and Al powder were added to the above solution, and ultrasonically oscillated for 20 minutes to make Al powder, BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0039] (4) Pour the above suspension into a watch glass, and dry in an oven at 100° C. to obtain a dielectric film.

[0040] (5) The above-mentioned dielectric film is hot-pressed into a sheet, and its dielectric properties are tested. Hot pressing conditions: 210°C, 10MPa, 25min.

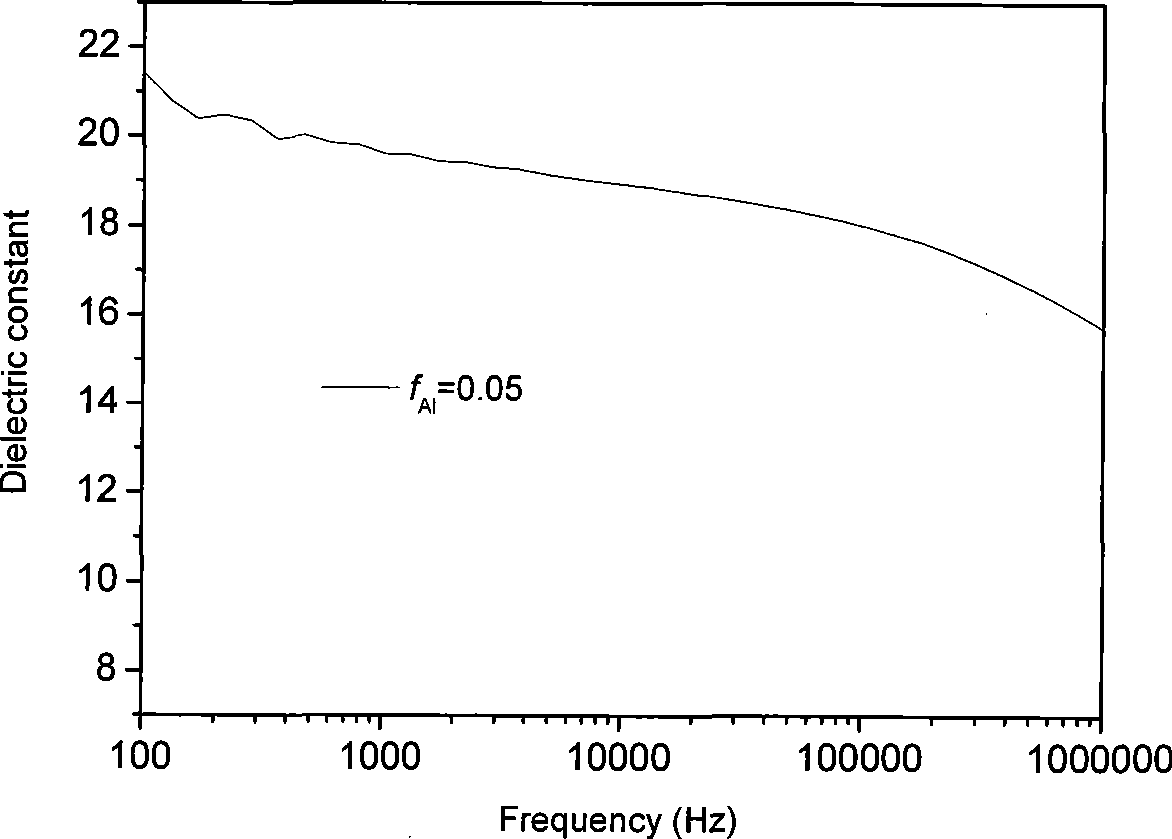

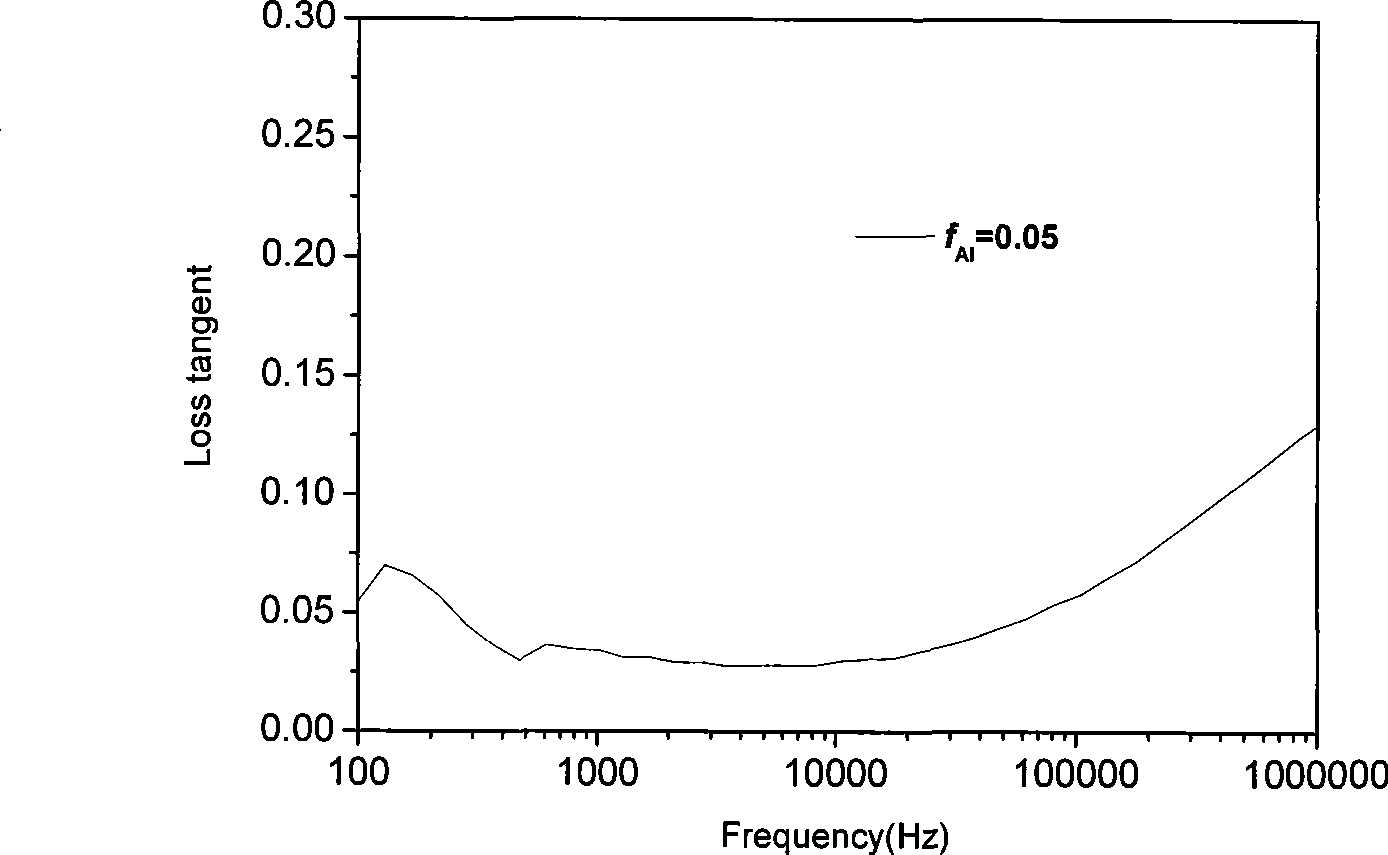

[0041] Figure 1a It is Al-BaT...

Embodiment 2

[0042] Example 2: preparation f Al Al-BaTiO = 0.25 3 / PVDF dielectric composites. The preparation steps are as follows:

[0043] (1) According to the volume fraction percentage f Al =0.25,f BaTiO3 =0.20,f PVDF =0.55 Weigh the raw materials, convert the volume fraction into mass and weigh 0.2250g, 0.3900g, 0.3300g in turn.

[0044](2) Add the weighed PVDF into 30ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0045] (3) BaTiO 3 and Al powder were added to the above solution, and ultrasonically oscillated for 20 minutes to make Al powder, BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0046] (4) Pour the above suspension into a watch glass, and dry in an oven at 100° C. to obtain a dielectric film.

[0047] (5) The above-mentioned dielectric film is hot-pressed into a sheet, and its dielectric properties are tested. Hot pressing conditions: 210°C, 10MPa, 25min.

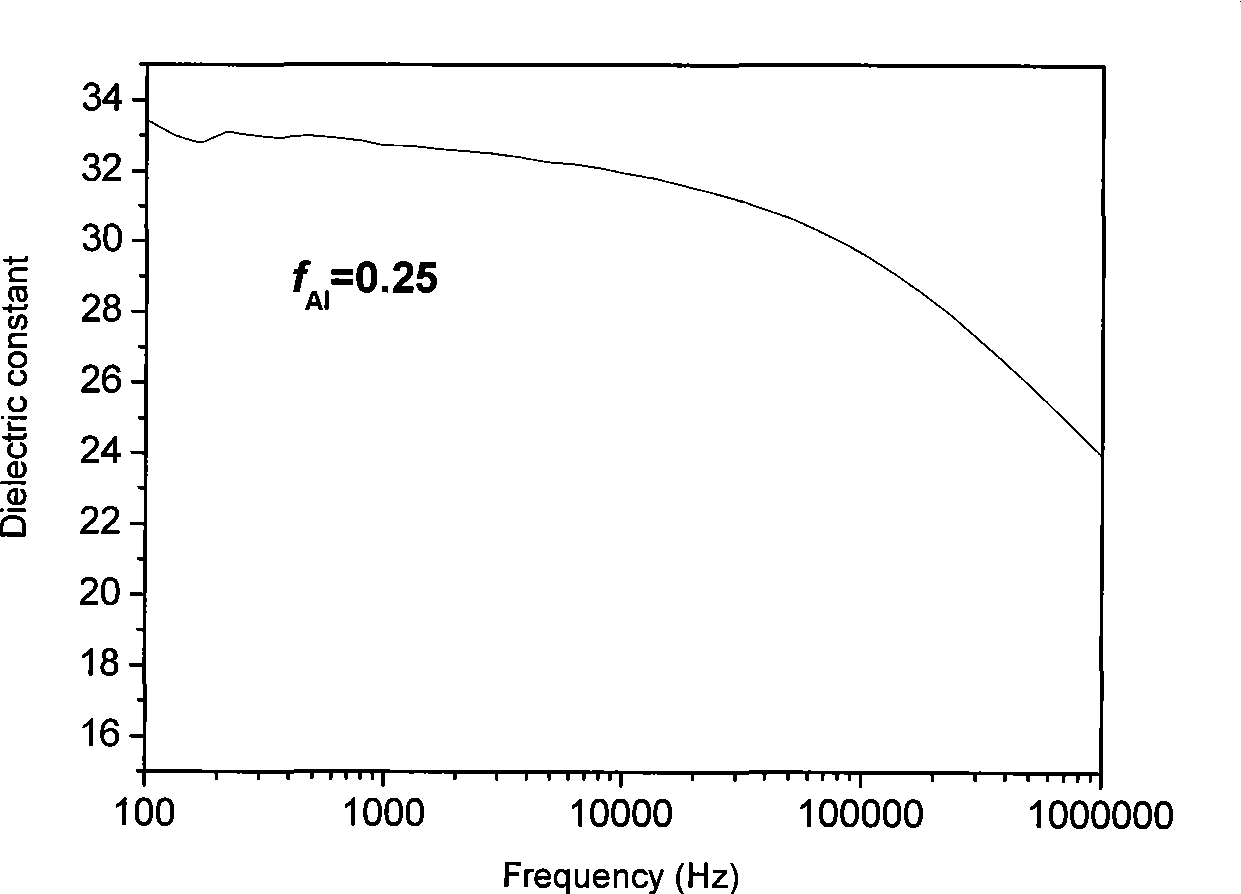

[0048] Figure 2a It is a graph of the relatio...

Embodiment 3

[0049] Example 3: preparation f Al Al-BaTiO = 0.18 3 / PVDF dielectric composites. The preparation steps are as follows:

[0050] (1) According to the volume fraction percentage f Al =0.18,f BaTiO3 =0.20,f PVDF =0.62, convert the volume fraction into mass and weigh 0.1620g, 0.3900g, 0.3720g in turn.

[0051] (2) Add the weighed PVDF into 35ml of N,N-dimethylformamide (DMF), fully dissolve to form a transparent solution.

[0052] (3) BaTiO 3 and Al were added to the above transparent solution, and ultrasonically oscillated for 20 minutes to make Al powder, BaTiO 3 Disperses evenly in solution to form a stable suspension.

[0053] (4) Pour the above suspension into a watch glass, and dry in an oven at 100° C. to obtain a dielectric film.

[0054] (5) The above-mentioned dielectric film is hot-pressed into a sheet, and the dielectric properties are tested. Hot pressing conditions: 210°C, 10MPa, 25min.

[0055] Figure 3a It is a graph of the relationship between diel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com