Gingeli antioxidation polypeptide composition and method for producing the same

A technology for antioxidant peptides and peptide compositions, which is applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., and can solve the problems of no patent reports in process research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

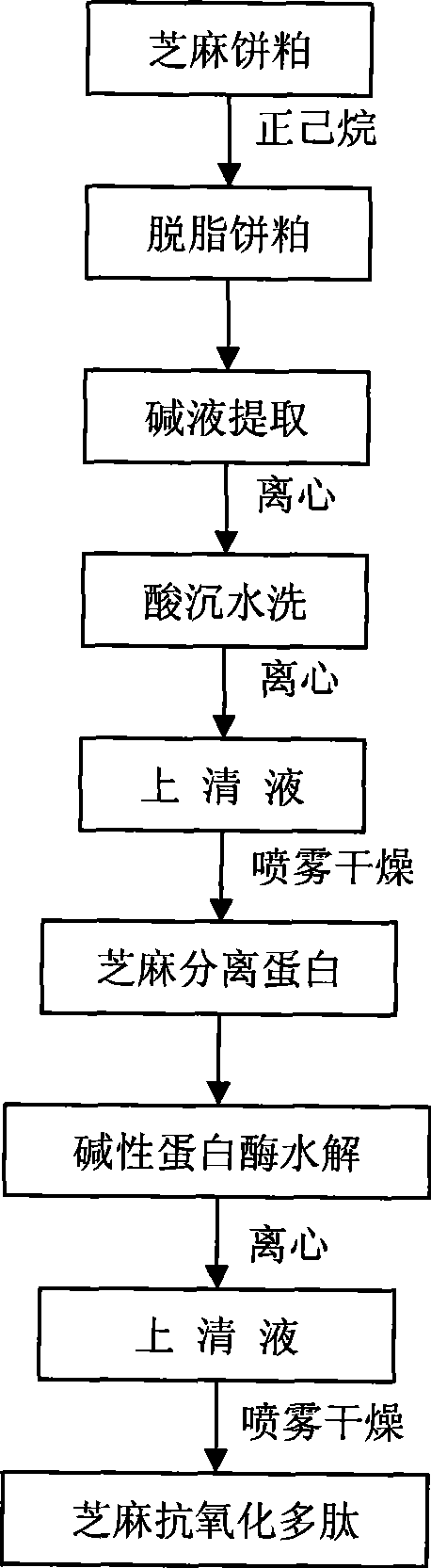

Method used

Image

Examples

Embodiment 1

[0020] (1) Sesame cake protein extraction

[0021] The sesame cake was pulverized with a pulverizer, and dried in an oven at 105°C for 1 h. Weigh 500g, according to the volume-to-mass ratio of n-hexane and sesame cake 3:1, stir and degrease in a water bath at 45°C for 3h, and centrifuge at 4000r / min for 15min. The supernatant was rotatably evaporated to recover n-hexane, the residue was extracted sesame oil, and the centrifuged sediment was repeated twice, and naturally dried to obtain defatted sesame cake with a residual oil rate of <1%.

[0022] Take 500g of defatted sesame cake, and dissolve it in NaHCO according to the ratio of material to liquid at 1:20 3 -In NaOH buffer solution, adjust the pH to 12.0, extract at 80°C for 1.5h, centrifuge at 4000r / min for 15min, repeat the extraction twice for the precipitate, combine the supernatant, adjust the pH to 5.0, concentrate, and then adjust the pH of the concentrate to 3.0 , to obtain acid heavy protein. The acid-precipitat...

Embodiment 2

[0042] (1) Sesame cake protein extraction is the same as in Example 1.

[0043] (2) Preparation of sesame antioxidant polypeptide:

[0044] Take 100 g of sesame protein obtained in step (1), dissolve it in 1000 mL of distilled water, adjust the pH to 8.0 with 1 mol / L NaOH solution, and preheat at 65° C. for 30 min. Add the same preheated alkaline protease, the dosage is 13.5:1 according to the ratio of substrate to enzyme, and adjust the pH to 8.0 with 2mol / L NaOH, keep the pH and temperature of the solution constant, stir for 6.6h, and after the reaction , inactivate the enzyme in a water bath at 85°C for 10 minutes, adjust the pH to 5.0, centrifuge at 4500 r / min for 10 minutes, take the supernatant and discard the precipitate.

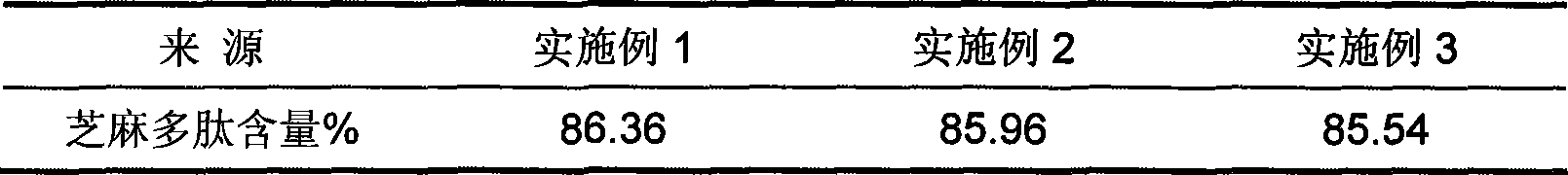

[0045] Spray-dry the enzymatic hydrolysis solution under the following drying conditions: air inlet 185±5°C, outlet air 85±5°C, and should be collected quickly after drying to obtain 90.32g of sesame antioxidant polypeptide composition product. The...

Embodiment 3

[0047] (1) Sesame cake protein extraction is the same as in Example 1.

[0048] (2) Preparation of sesame antioxidant polypeptide:

[0049] Take 100 g of sesame protein obtained in step (1), dissolve it in 1000 mL of distilled water, adjust the pH to 9.0 with 1 mol / L NaOH solution, and preheat at 55 ° C for 30 min. Add the same preheated alkaline protease, the dosage is 15.74:1 according to the ratio of substrate to enzyme, and adjust the pH to 9.0 with 2mol / L NaOH, keep the pH and temperature of the solution constant, stir for 7.45h, and after the reaction, Inactivate the enzyme in a water bath at 90°C for 10 minutes, adjust the pH to 5.5, centrifuge at 4500 r / min for 10 minutes, take the supernatant and discard the precipitate.

[0050] Spray-dry the enzymatic hydrolysis solution under the following drying conditions: air inlet 185±5°C, outlet air 85±5°C, and should be collected quickly after drying to obtain 92.5g of sesame antioxidant polypeptide composition product. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com