Nano-hollow sphere structured amorphous zinc oxide and method for producing the same

A technology of hollow spheres and amorphous state, which is applied in the field of nano-hollow sphere structure amorphous zinc oxide and its preparation, can solve problems that have not been seen yet, and achieve the effects of maximum utilization, good dispersion, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Using oxygen in the air as an active oxygen source to prepare amorphous zinc oxide with nano hollow spheres

[0024] Step 1: Weigh 126.466mg of zinc stearate, 2.0g of n-hexadecylamine, 143.6mg of 1,2-hexadecanediol and 2.0g of tri-n-octylphosphine oxide, and put the above precursors into a capacity of 25ml In the three-necked flask, the middle one was plugged with a rubber stopper, and a thermometer was inserted into the stopper, while nitrogen gas was introduced into the other two ports, while nitrogen gas was discharged, and the nitrogen gas was discharged from one port, which was immersed in water with a rubber tube.

[0025] Step 2: Keep nitrogen protection all the time, and then start to raise the temperature slowly, with an average of 0.5 degrees / min. The solution in the bottle is always clear throughout the process until the temperature rises to 260°C. Keep this temperature for 2 hours, and the reaction solution turns light yellow;

[0026] Step 3: rem...

Embodiment 2

[0029] Example 2: Using hydrogen peroxide as an active oxygen source to prepare amorphous zinc oxide with nano hollow sphere structure

[0030] Step 1: This operation is exactly the same as Step 1 in Example 1.

[0031] Step 2: This operation is exactly the same as Step 2 in Example 1.

[0032] Step 3: Add 1 mL of hydrogen peroxide dropwise, keep warm at 260° C. for 4 hours, and cool down naturally. The reaction solution turns orange, which is the crude reaction product.

[0033] Step 4: This operation is exactly the same as Step 4 in Example 1.

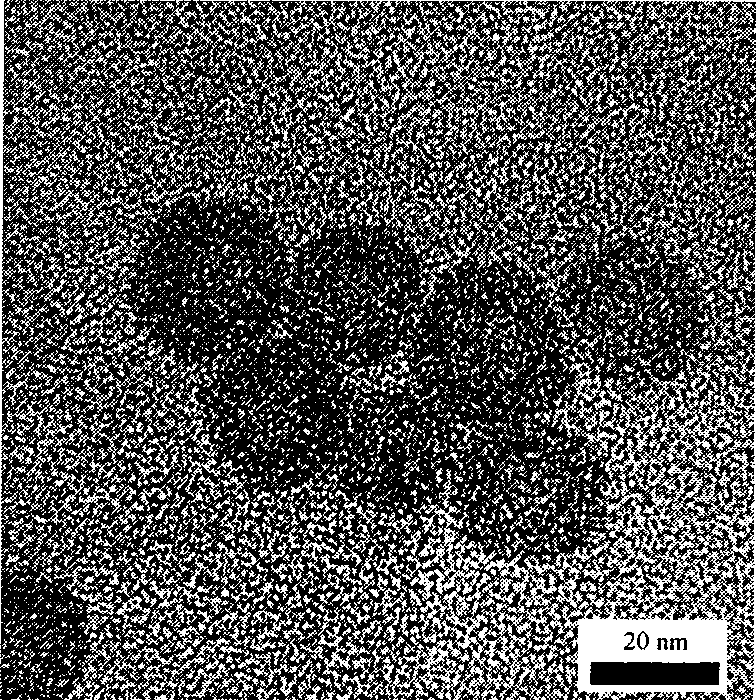

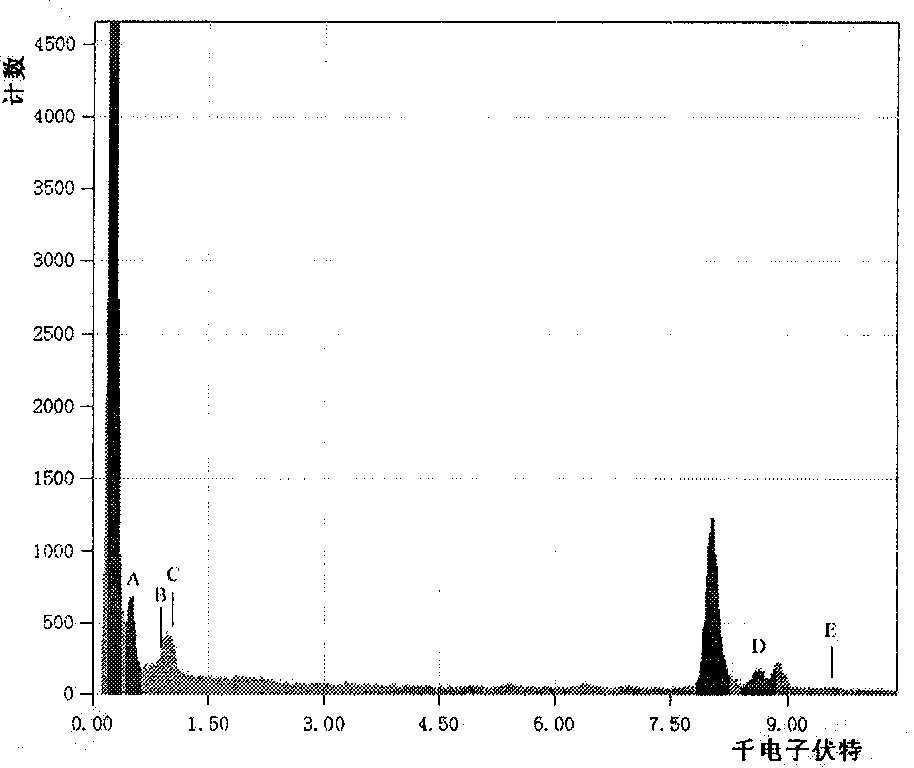

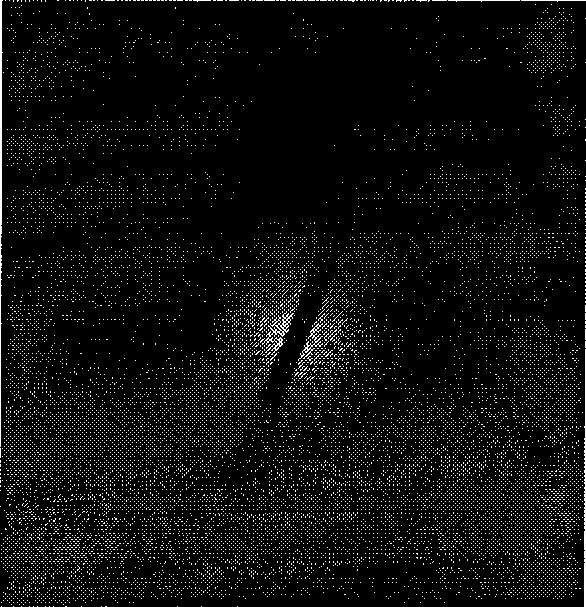

[0034] From its transmission electron microscope photo Figure 7 As shown, the obvious hollow structure can be seen, with a diameter of 15nm±3nm; from the X-ray energy scattering spectrum Figure 8 It can be seen that the A signal peak comes from the oxygen element in the product, and the B, C, D, and E signal peaks come from the zinc element in the product.

[0035] It can be seen from the above embodiments of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com