Overlaying welding method of large area carbide alloy of workpiece wear layer

A hard alloy and wear-resistant layer technology, which is applied in the field of large-area wear-resistant layer and large-area cobalt-based hard alloy surfacing welding, can solve the problems of large workpiece size, achieve quality assurance, reduce welding stress, and solve Effect of preheat temperature and discontinuity of soldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

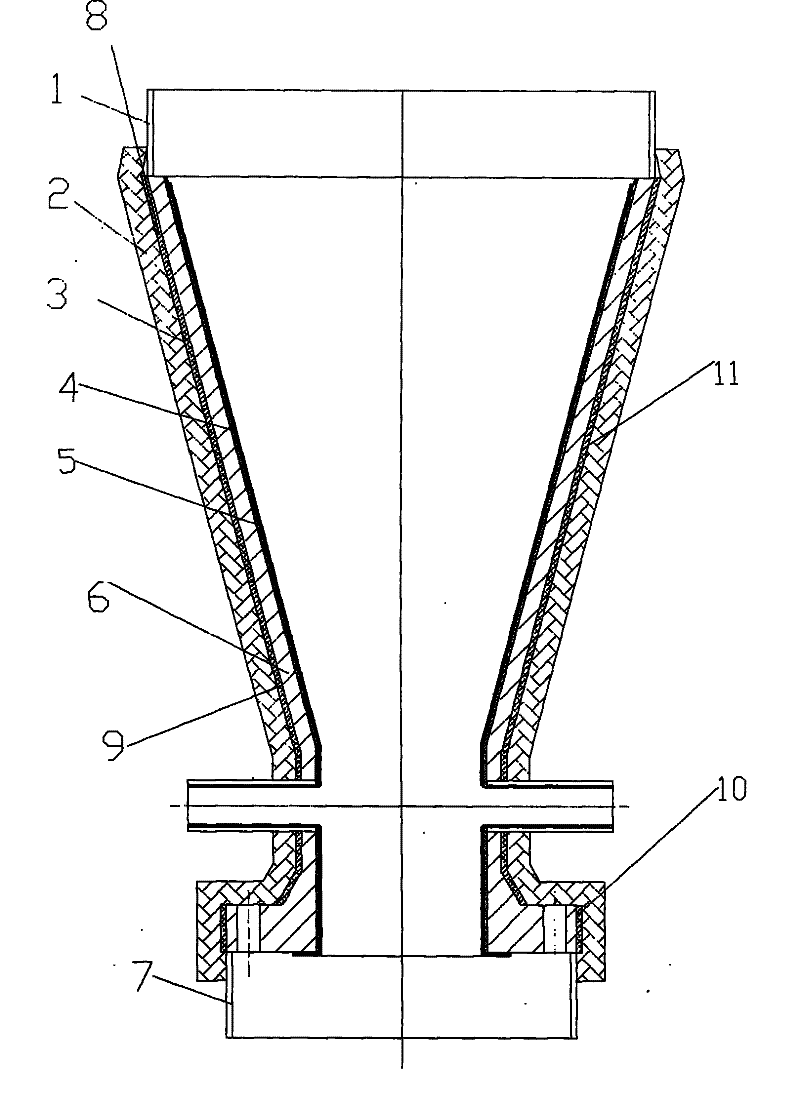

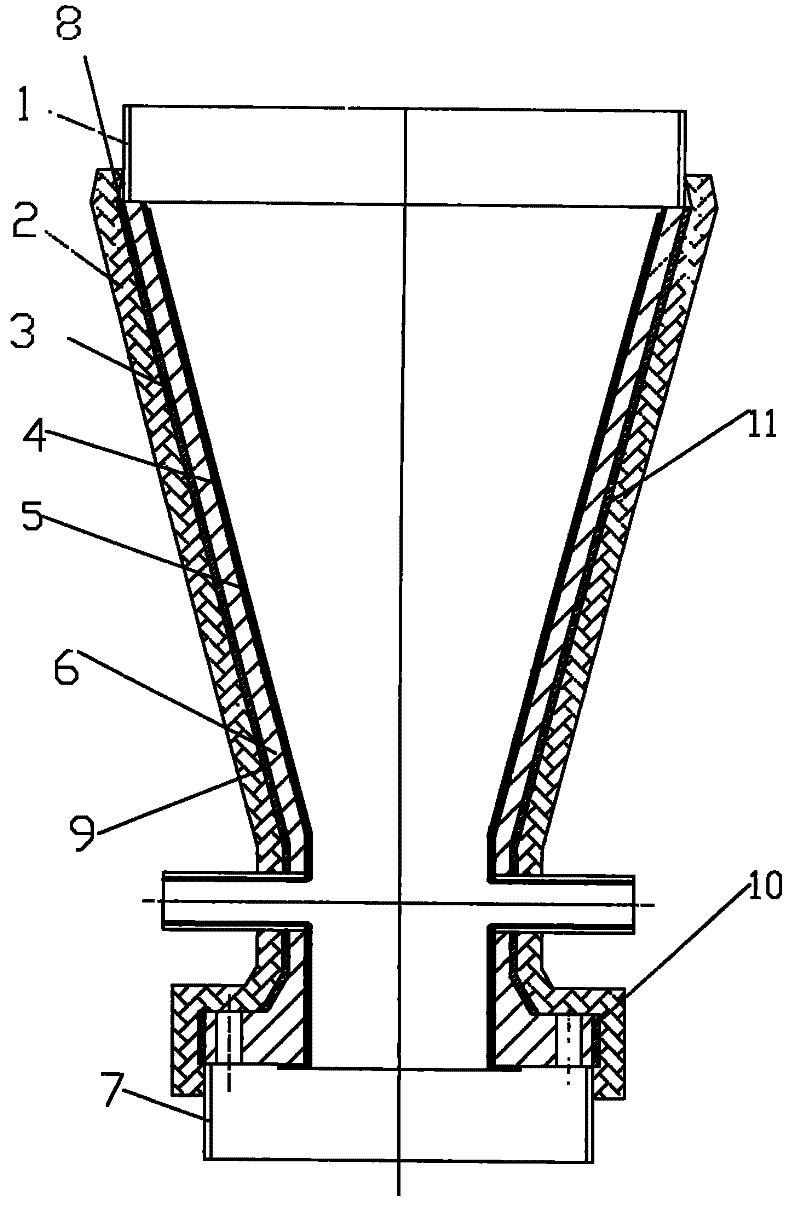

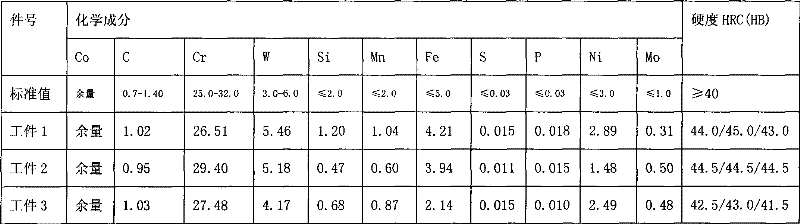

[0034] Referring to Figure 1, the lower part of a piece of equipment (Φ1300 / Φ219×1000mm) needs to be surfacing with a 5mm thick wear-resistant, corrosion-resistant, heat-resistant and oxidation-resistant cobalt-based cemented carbide layer 4 (Stillite6, ECoCr-A).

[0035] Carbide surfacing adopts manual electrode arc welding (SMAW) welding method, the material of the base steel part 6 is 16MnR, the transition layer surfacing material is E309Mo (A312) with a specification of Φ4.0, and the hard alloy surface layer surfacing material Stillite6 (EcoCr-A), the specification is Φ4.0, the transition layer 5 is surfacing with two layers, and the surface layer 4 is surfacing with two layers. The specific implementation measures are as follows:

[0036] 1) Processing of the steel base of the surfacing workpiece: the base of the surfacing workpiece is made of two pieces of tailor welding, and each piece is formed by pressing. The ellipticity of the large and small mouths of the workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com