Optical waveguide laser, optical waveguide amplifier and preparation method thereof

A technology of waveguide amplifiers and waveguide lasers, applied in the field of lasers, can solve problems such as complex processes, reduced utilization value, and high material requirements, and achieve the effect of simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

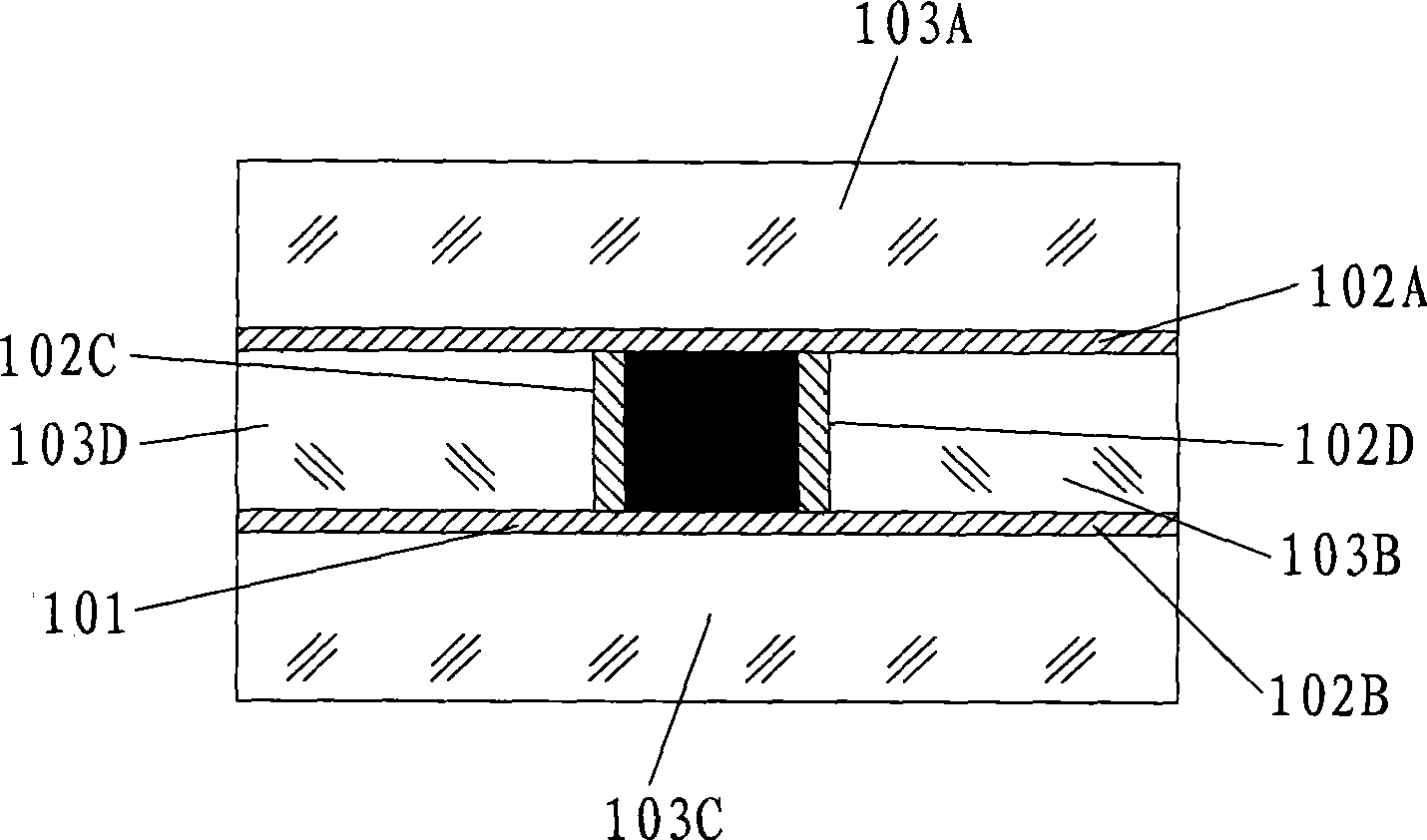

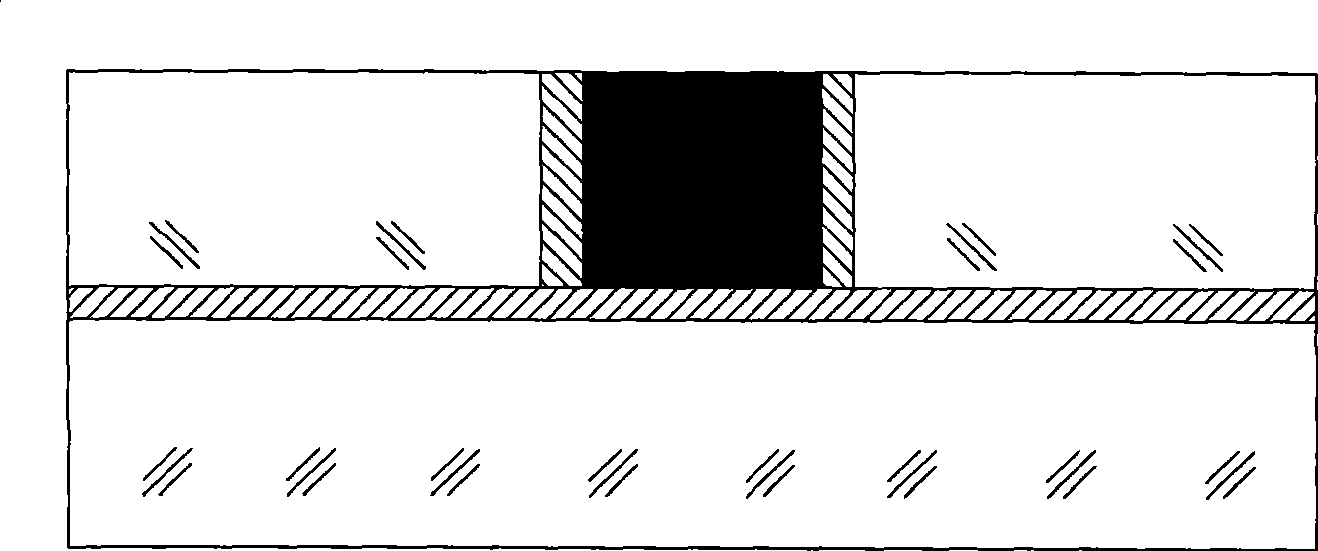

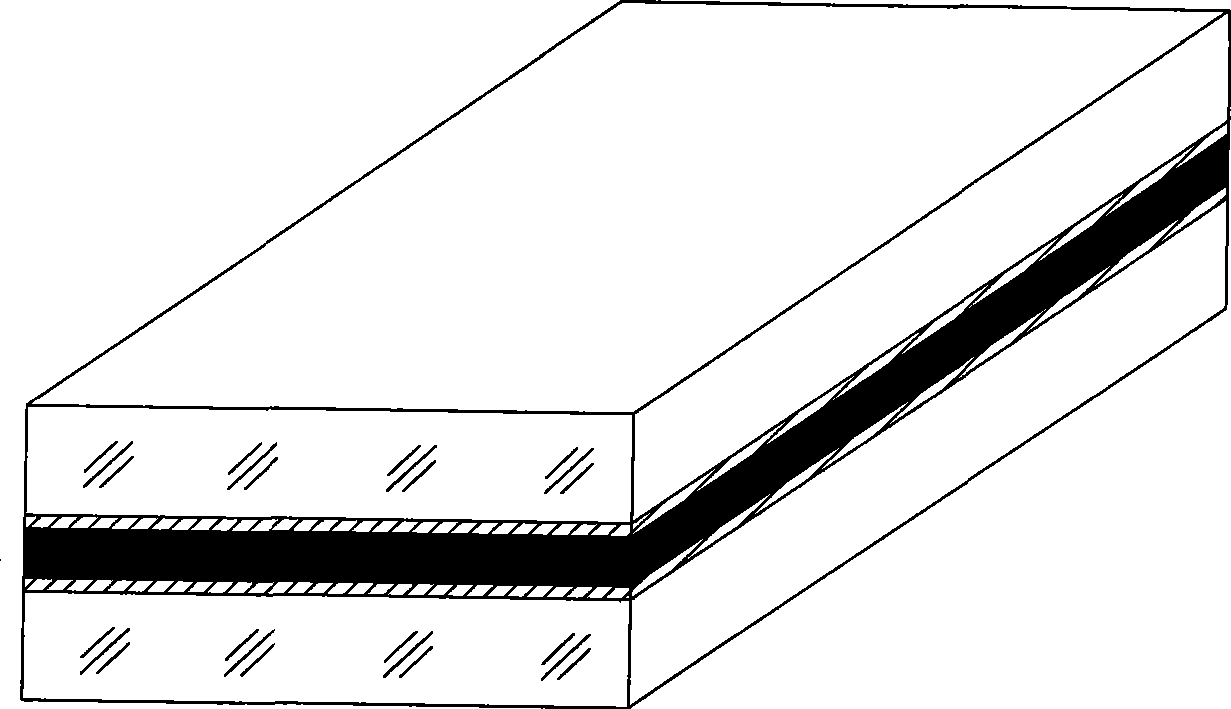

[0054]As shown in Figure 1 (a), it is a schematic cross-sectional view of the first waveguide cavity structure of the present invention, wherein 101 is a laser gain medium with a refractive index n1; 102A, 102B, 102C, and 102D are adhesive layers or deepening optical adhesive films layer; the refractive index is n2, wherein the refractive index is n1>n2; 103A, 103B, 103C, and 103D are optical substrate materials, thus forming a waveguide structure at 101. The structure in Figure 1(b) is similar to that in Figure 1(a), which is a waveguide structure with adhesive layers on three sides and air on one side. Figure 1(c) The upper and lower sides of the waveguide cavity gain medium are surrounded by substrate material or adhesive layer, and the left and right sides are air.

[0055] For LD pumping, the divergence angle in the fast axis direction is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com