Chinese medicine glue rapid-release preparation for oral cavity and method for producing the same

An immediate-release preparation and manufacturing method technology, applied in the field of traditional Chinese medicine glue oral immediate-release preparations and its manufacturing, can solve problems such as disappearance and variety shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

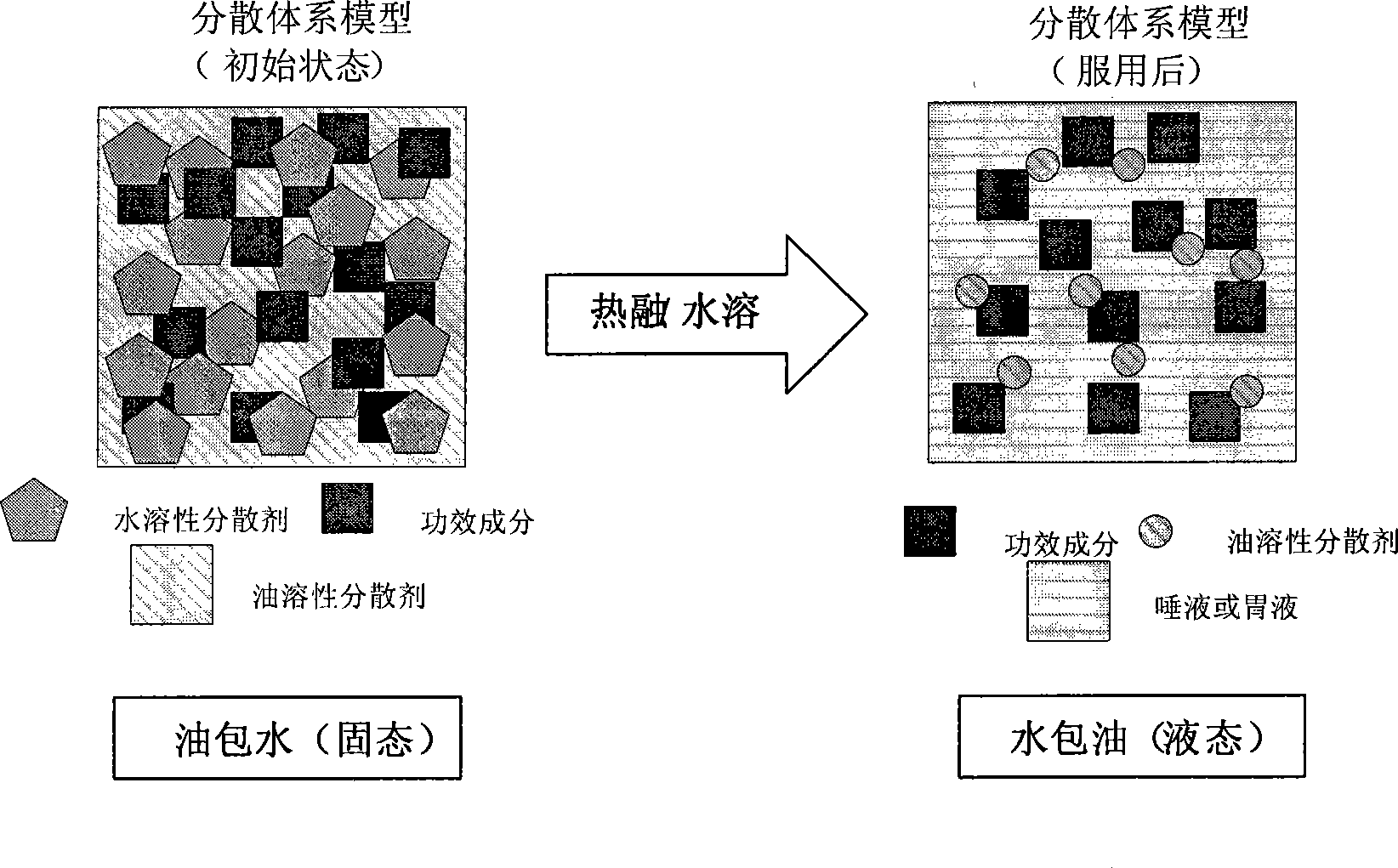

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] Embodiment 1: the manufacture method of donkey-hide gelatin preparation

[0147] (1) Material preparation: 200kg of main ingredients (6 parts of donkey-hide gelatin, 7 parts of hawthorn, 2 parts of wolfberry, 2 parts of jujube), auxiliary materials (100 kg of xylitol, 150 kg of hydrogenated vegetable oil, 10 kg of lecithin)

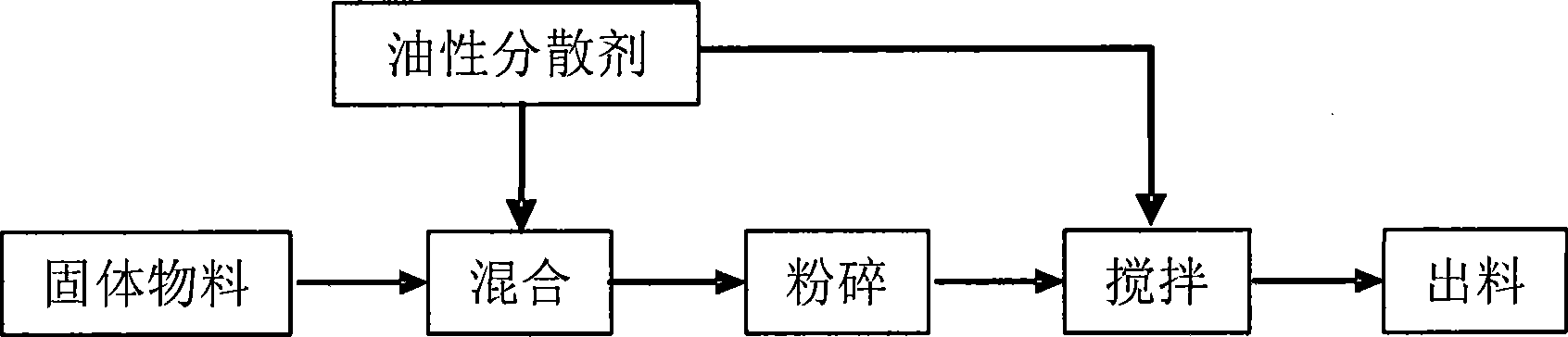

[0148] (2) Slurry preparation: refinement first - using semi-dry method, roller grinding method (see Image 6). Specifically: crush 200kg of main ingredients to 100-200 meshes, add 100kg of xylitol and 90kg of hydrogenated vegetable oil (36-60°C) and mix them, and pre-grind them in a two-roll mill (or three-roll mill) to 60-150 microns , and then enter the five-roll mill (or three-roll mill) for grinding to 20-33 microns. Liquefaction—put the material into a refiner (blender) for refining (stirring) for 3 to 6 hours, during which the remaining hydrogenated vegetable oil and lecithin are gradually added according to the viscosity of the material u...

Embodiment 2

[0150] Embodiment 2: the manufacture method of deer horn glue preparation

[0151] (1) Material preparation: 200kg of main ingredients (9 parts of deer horn glue, 1 part of microcrystalline cellulose), auxiliary materials (300kg of sugar, 300kg of refined vegetable oil, 10kg of lecithin)

[0152] (2) Slurry preparation: refinement and liquefaction at the same time - using wet method and fine grinding method (see Figure 7 ). Specifically: mix and grind 200kg of the main ingredients to 15-200 meshes, add 300kg of sugar powder and 270kg of refined vegetable oil (38-60°C) successively (or add them after mixing) and grind them to 26-30 microns. Reserve 30kg of refined vegetable oil and add it together with lecithin 1 hour before the end.

[0153] (3) Molding: after fine grinding, the material is discharged, poured into the preformed aluminum-plastic mold and sealed, cooled and shaped, 10g / piece.

Embodiment 3

[0154] Embodiment 3: the manufacture method of tortoise shell gum preparation

[0155] (1) Materials: 200kg tortoise shell glue, auxiliary materials (200kg isomalt, 100kg lactose, 300kg cocoa butter, 10kg lecithin)

[0156] (2) Slurry preparation: refinement and liquefaction at the same time -: wet method, ball milling method (see Figure 8 ). Specifically: crush 200kg of tortoise shell gum to 10-200 mesh, add 200kg of isomalt, 100kg of lactose and 300kg of cocoa butter (39-60°C) successively (or add after mixing) into a ball mill and grind to 30-33 microns . Lecithin is added successively during the grinding process.

[0157] (3) Molding: Discharge after ball milling, pour into a pre-set mold after temperature adjustment, then cool and solidify, take out the package, 10g / piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com