Method for rapid medium-low temperature dry distillation of coal by using microwave

A low-temperature, rapid technology, applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of reducing the content of active components in gas, unfavorable comprehensive utilization of gas, and low coal pyrolysis speed, so as to improve the pyrolysis speed and effectively Conducive to comprehensive utilization and recycling, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

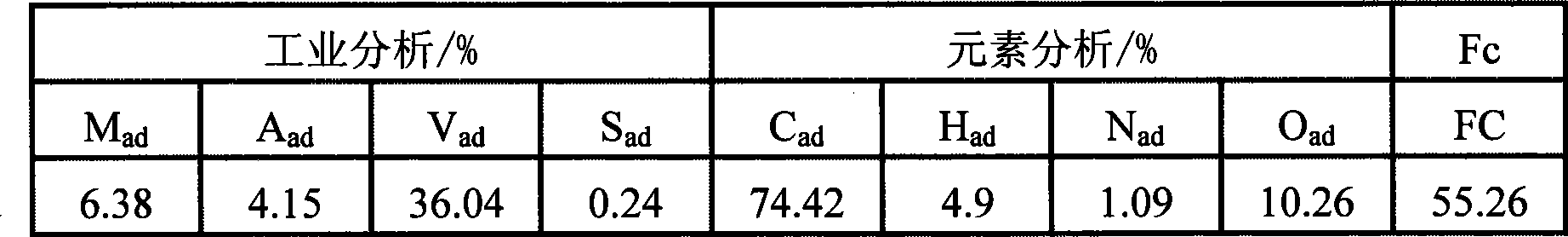

[0024] Take 50g of Jurassic coal from a certain area in northern Shaanxi, the particle size is 200mm, and its composition is shown in Table 1. Put the Jurassic coal into a microwave-heated reactor with a microwave frequency of 0.3GHz to 300GHz, a final heating temperature of 700°C, and pyrolysis for 7min to 30min. After the tar was collected, the dry distillation gas was sampled and analyzed.

[0025] Table 1 Analysis results of raw coal

[0026]

[0027] Table 2 Analysis results of dry distillation gas

[0028] N 2 CO CH 4 CO 2 H 2 O 2 C 2 2.59 16.19 21.31 -- 59.76 0.15 2.24

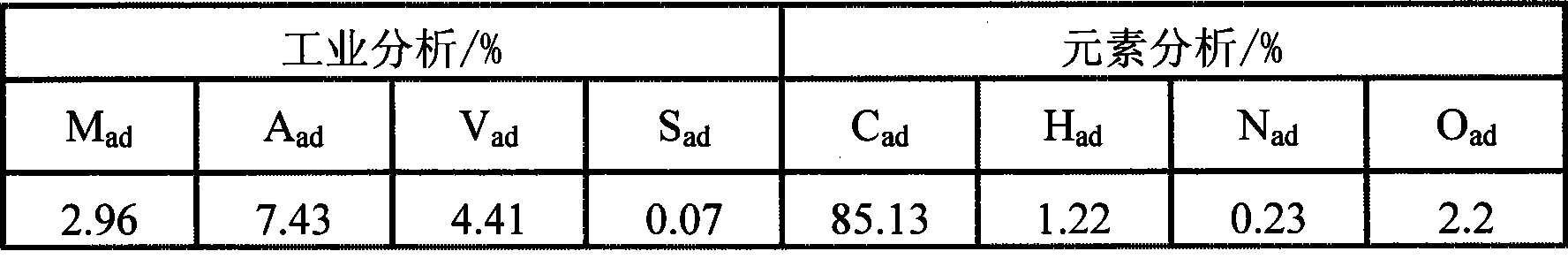

[0029] Table 3 Analysis results of semi-coke (semi-coke)

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com