Developing solution for heat-sensitive positive picture CTP plate

A heat-sensitive positive image and developer technology, applied in the field of developer, can solve the problems of poor dispersion stability, poor fatigue resistance, and small tolerance of color photoresist, and achieve good dot reduction, good ink retention, and wide operating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

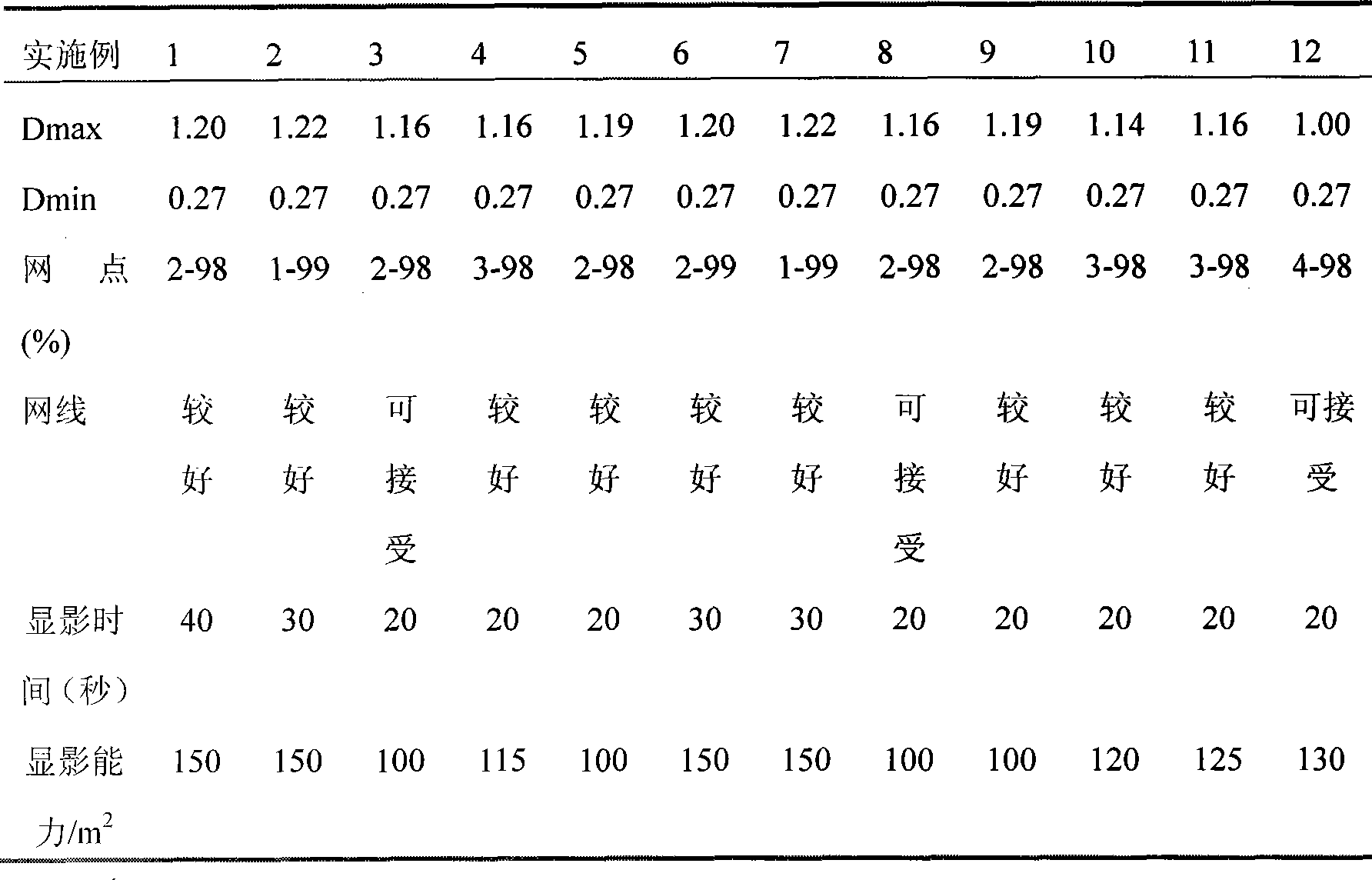

Examples

Embodiment 1

[0035] (1) Preparation of developing solution

[0036] Each component of developing solution and the parts by weight of each component are as follows:

[0037] (A): SiO 2 / Na 2 O 11.1 parts by weight, modulus 3

[0038] KOH 4 parts by weight

[0039] (B): 1 part by weight of sodium phosphate

[0040] (C): 8 parts by weight of glycerin

[0041] (D): Zonyl TM FSN 4 parts by weight

[0042] (E): 71.9 parts by weight of water

[0043] First add 80 parts by weight of water into a plastic container, then add 8 parts by weight of glycerin and 4 parts by weight of ZonylTM FSN, slowly mix until the bottom of the thick matter dissolves, add 11.1 parts by weight of SiO2 / Na2O with a modulus of 3 , and then add 1 weight part of KOH and 1 weight part of sodium phosphate, stir rapidly until dissolved, and add water to 100 weight parts. To test the conductivity, adjust the conductivity to 91-92mS / cm by adjusting the amount of KOH, and the total amount of KOH is 4 parts by weig...

Embodiment 2

[0048] (1) Preparation of developing solution

[0049] Each component of developing solution and the parts by weight of each component are as follows:

[0050] (A): SiO 2 / Na 2 O 13.7 parts by weight Modulus 2.8

[0051] KOH 4 parts by weight

[0052] (B): 1 part by weight of sodium hexametaphosphate

[0053] Sodium phosphate 0.5 parts by weight

[0054] (C): 8 parts by weight of glycerin

[0055] (D): Zonyl TM FS300 4 parts by weight

[0056] (E): 68.8 parts by weight of water

[0057] The method of Example 1 was repeated for each component in the above parts by weight to obtain a developer solution with a pH value of 12.5.

[0058] (2) Evaluation method of developer

[0059] The developing ability of the developing solution was evaluated using the evaluation method in Example 1, and the evaluation results are listed in Table 1.

Embodiment 3

[0061] (2) Preparation of developing solution

[0062] Each component of developing solution and the parts by weight of each component are as follows:

[0063] (A): SiO 2 / Na 2 O 29.8 parts by weight Modulus 2.6

[0064] Diethanolamine 2.8 parts by weight

[0065] KOH 4 parts by weight

[0066] (B): 2 parts by weight of sodium pyrophosphate

[0067] (C): 8 parts by weight of glycerin

[0068] (D): Zonyl TM FSE 4 parts by weight

[0069] (E): 49.4 parts by weight of water

[0070] Repeat the method of Example 1 for each of the above components to obtain a developing solution, the pH of which is 14.

[0071] (2) Evaluation method of developer

[0072] The developing ability of the developing solution was evaluated using the evaluation method in Example 1, and the evaluation results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com